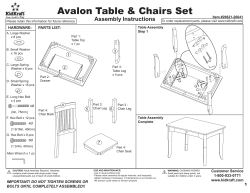

Cap Screws & Bolts