nanocellulose reinforced pvdf speaker

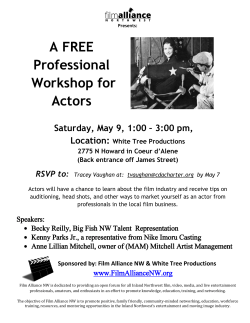

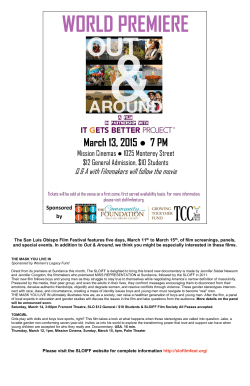

COLLEGE OF ENGINEERING Chemical, Biological & Environmental Engineering NANOCELLULOSE REINFORCED PVDF SPEAKER Background Hussain Al Zayer, Alex Van, Greg Wu Sponsored by Dr. John Simonsen • Piezoelectric materials generate mechanical strain proportional to applied electric charge • PVDF is a piezoelectric polymer when it is in the β-phase (See Figure 2) • PVDF film exhibits piezoelectric behavior in specific planes relative to an applied electric field (See Figure 1) • Crystalline nanocellulose (CNC) filler provides electrical and mechanical properties and potential cost savings • Piezoelectric PVDF films can serve as an audio speaker Objective Investigate the use of crystalline nanocellulose (CNC) as a filler in polyvinylidene fluoride (PVDF) films for use in two-dimensional audio speakers. Tests were performed to investigate the effect of: • Filler content (% CNC) • Thickness of films (µm) The effect of these parameters were analyzed by looking at • Volume and sound quality of speaker • Frequency range of produced sound Results Future Work • Construct high voltage operational amplifier • Try new frame designs (ring-shaped, different sizes) • Poling the PVDF films by subjecting to large electric field • Perform tests to determine mechanical robustness • Cast with other methods to get wrinkle free PVDF films, to improve speaker sound quality • Explore relationship between direction manufacturing geometry and volume produced • Compare thickness and sound results at same content filler of nanocellulose Comparison of frequency vs. audio volume for different filler contents of nanocellulose in PVDF films and film coatings are summarized in the plots below. https://www.americanpiezo.com/knowledge-center/piezo-theory/piezoelectric-constants.html http://pubs.rsc.org/en/content/articlehtml/2013/ra/c3ra45134h -55 -60 Methods • PVDF film is cast in a solution of nanocellulose and DMAC for four hours -75 -90 Acknowledgment Frequency (Hz) Figure 4: Original frame design made use of four c-clamps to secure film and did not include a transformer or coaxial cable. For testing a small weight was placed on the film to help produce noise. Figure 5: Volume between frequencies 800-16,000 Hz for a 0% CNC film that was 30 μm thick. The film has been metalized with silver ink. Large peaks below 1000 Hz is due to background noise. -50 -55 -55 -60 -60 -65 -65 Volume (dB) -50 -70 -75 -85 -85 -90 -90 Figure 6: Volume produced between frequencies 80016,000 Hz for a 16% CNC film that was 37 µm thick film, The film has been metalized with silver ink. The CNC filled film has more peaks that pass -66 dB than the 0% film. • Meisam Shir Mohammadi – PhD Student • Andy Brickman – Electrical Assistance • Milo Clauson – Frame Design • Dr. Phil Harding – General Guidance -75 -80 • Dr. John Simonsen – Project Sponsor • Scott Hong Cheng Tan – Frame reconstruction -70 -80 Frequency (Hz) Figure 3: CNC and DMAC solution is applied in rotary caster with a heat gun to maintain 60 oC for four hours -70 -85 Volume (dB) • Frequency of applied field is adjusted with waveform generator to determine minimum frequency -65 -80 • Thickness is then measured with a micrometer • Film is coated with silver ink on both sides to create conductive film • PVDF films filled with nanocellulose has better sound quality compared to non-filled films • Sputter coated PVDF films produce higher volume compared to films coated with silver ink -50 Volume (dB) Figure 1: Different strains that a piezoelectric film can experience for an electric field in a given direction Conclusion Figure 2(a): α-phase of PVDF Figure 2 (b): β-phase of PVDF where the fluorine atoms are aligned on one side and hydrogen on the other. Frequency (Hz) Figure 7: Volume by a 16% CNC that was 37 µm thick film. The film has been metalized by sputter coating with gold. Large peaks below 1000 Hz is due to both background noise and noise produced by the film.

© Copyright 2026