File - Colbourne College

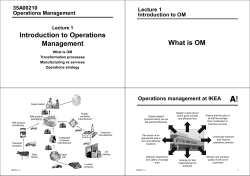

CLAUDETTE P.BENNETT Operation is that part of an organization, which is concerned with the transformation of a range of inputs into services having the required quality level. Management is the process, which combines and transforms various resources used in the operations of the organization into value added services in a controlled manner as per the policies of the organization Operations Management, according to Joseph G .Monks is the process whereby resources, flowing within a defined system, are combined and transformed by a controlled manner to add value in accordance with policies communicated by management. Management activities which are involved in manufacturing certain products, is called production management and if it is services then the management s is called as operations management. Prior to 1900 ◦ ◦ ◦ ◦ Cottage industry produced custom-made goods. Watt’s steam engine in 1785. Whitney’s standardized gun parts in 1801. Industrial Revolution began at mid-century. Scientific Management (Frederick W. Taylor) Other Management Pioneers ◦ Systematic approach to increasing worker productivity through time study, standardization of work, and incentives. ◦ Viewed workers as an interchangeable asset. ◦ Frank and Lillian Gilbreth Motion study and industrial psychology Scheduling and the Gantt chart ◦ Henry L. Gantt Moving Assembly Line (1913) Hawthorne Studies ◦ Labor specialization reduced assembly time. ◦ Yielded unexpected results in the productivity of Western Electric plant workers after changes in their production environment. ◦ Led to recognition of the importance of work design and employee motivation. Operations Research (Management Science) OM Emerges as a Field The Marriage of OM and IT ◦ Outgrowth of WWII needs for logistics control and weapons-systems design. ◦ Seeks to obtain mathematically optimal (quantitative) solutions to complex problems. ◦ 1950–1960, OM moved beyond industrial engineering and operations research to the view of the production operation as a system. ◦ Integrated solutions approaches Business process reengineering Supply chain management Systems integration (SAP) Operations Management in Services Integration of Manufacturing and Services ◦ OM concepts can apply to both manufacturing and service operations. ◦ Conducting world class operations requires compatible manufacturing and service operations. The primary goals of the organizations are related market opportunities. Economy and efficiency of conversion operations are the secondary goals. After assessing the potential within an industry to its competitors. In doing so, priorities are established among the following four characteristics: ◦ Quality (product performance), Cost efficiency (low product price), Dependability (reliable, timely delivery of orders to customers), Flexibility (responding rapidly with new products or changes in volume). 1. Strategic (long-range) Needs of customers (capacity planning) 2. Tactical (medium-range) Efficient scheduling of resources 3. Operational planning and control (short-range) Immediate tasks and activities The operation system includes both manufacturing sector as well as service sector, but when you use the word PM, you should be careful to note that it refers to the manufacturing sector but not the service sector. An operation was defined in terms of the mission for the organization, technology it employs and the human and managerial processes it involves. Operations in an organization can be categorized into Manufacturing Operations and Service operations. Operations Management concern with the conversion of inputs into outputs, using physical resources, so as to provide the desired utilities to the customer while meeting the other organizational objectives of effectiveness, efficiency and adoptability. It distinguishes itself from other functions such as personnel, marketing, finance, etc. by its primary concern for ‘conversion by using physical resources’. Production and Operations Management functions: 1. 2. 3. 4. 5. 6. 7. 8. Location of facilities. Plant layouts and Material Handling. Product Design. Process Design. Production and Planning Control. Quality Control. Materials Management. Maintenance Management. Operational Management’s function focuses on adding value through the transformational process of converting inputs into outputs. ◦ ◦ ◦ ◦ ◦ ◦ Physical: manufacturing Locational: transportation Exchange: retailing Storage: warehousing Physiological: health care Informational: telecommunications Production is defined as ‘the step-by-step conversion of one form of material into another form. Production function is ‘the part of an organization, which is concerned with the transformation of a range of inputs into the required outputs (products) having the requisite quality level’. Production management is ‘a process of planning, organizing, directing and controlling the activities of the production function. It combines and transforms various resources used in the production subsystem of the organization into value added product in a controlled manner as per the policies of the organization’. Effective production and operations management can: 1. Lower a firm’s costs of production. 2. Boost the quality of its goods and services. 3. Allow it to respond dependably to customer demands. 4. Enable it to renew itself by providing new products. A production function can be expressed in a functional form as the right side of Q= f (X1,X2,X3,…..Xn) where: Q=quantity of output X1,X2,X3,…..Xn=quantities of factor inputs (such as capital, labor, land or raw materials). The production managers have the prime responsibility oversee the work of people and machinery to convert inputs (materials and resources) into finished goods and services. • Four main tasks: 1. Planning the Production Process 2. Begins by choosing what goods or services to offer customers. 3. Convert original product ideas into final specifications. 4. Design the most efficient facilities to produce those products. The objective of the production management is ‘to produce goods and services of Right Quality and Quantity at the Right time and Right manufacturing cost’. 1. Right Quality: The quality of product is established based upon the customers need. 2. Right Quantity: The manufacturing organization should produce the products in right number. Right Time: Timeliness of delivery is one of the important parameter to judge the effectiveness of production department. Right Manufacturing Cost: Manufacturing costs are established before the product is actually manufactured. Job-Shop Production: manufacturing one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost. Batch Production: job pass through the functional departments in lots or batches and each lot may have a different routing. Mass Production: Manufacture of discrete parts or assemblies using a continuous process are called Mass Production. This production system is justified by very large volume. Continuous Production: Production facilities are arranged as per the sequence of production operations from the first operations to the finished product. The items are made to flow through the sequence of operations through material handling devices such as conveyors, transfer devices, etc. Managing Operations involves planning, organizing, and controlling the activities, which affect human behavior through models. ◦ Planning is the activity that establishes a course of action and guide future decision-making. ◦ Organizing is the activities that establish a structure of tasks and authority. ◦ Controlling is the activities that assure the actual performance in accordance with planned performance. Controlling costs, quality, and schedules are the important functions here. 1. Behavior: Operations managers are concerned with the activities, which affect human behavior through models. 2. Models: Models represents schematic representation of the situation, which will be used as a tool for decisionmaking. Following are some of the models used. Objectives of Operations Management can be categorized into Customer Service and Resource Utilization. ◦ Customer Service - the satisfaction of customer wants. ◦ Resource Utilization - to utilize resources for the satisfaction of customer wants effectively. Operations management is concerned essentially with the utilization of resources, i.e. obtaining maximum effect from resources or minimizing their loss, under utilization or waste. Operations management is concerned with the achievement of both satisfactory customer service and resource utilization The operations managers have the prime responsibility for processing inputs into outputs. They must bring together under production plan that effectively uses the materials, capacity and knowledge available in the production facility. Strategic planning is the process of thinking through the current mission of the organization and the current environmental conditions facing it, then setting forth a guide for tomorrow’s decisions and results. Strategic planning is built on fundamental concepts: that current decisions are based on future conditions and results. Strategic Planning for Production and Operations: - In the production or operations function, strategic planning is the broad, overall planning that precedes the more detailed operational planning. Strategic Planning Approaches for Production/Operations:- There are many approaches to strategic planning. The key point is that operations strategies must be consistent with the overall strategies of the firm. Strategic Planning—Forced Choice Model: - This model forcing management to develop strategic options for operations A Strategic Planning Operations Model: - Concept is that manufacturing strategy tries to link the policy decisions associated with operations to the marketplace, the environment, and the company’s overall goals. Productivity is defined in terms of utilization of resources, like material and labor. Productivity is closely inked with quality, technology and profitability. Hence, there is a strong stress on productivity improvement in competitive business environment. Productivity can be improved by (a) controlling inputs, (b) improving process so that the same input yields higher output, and (c) by improvement of technology. These aspects are discussed in more detail in the lesson on Productivity Management. Productivity Analysis: Trend analysis: Studying productivity changes for the firm over a period of time. 2. Horizontal analysis: Studying productivity in comparison with other firms of same size and engaged in similar business. 3. Vertical analysis: Studying productivity in comparison with other industries and other firms of different sizes in the same industry. 4. Budgetary analysis: Setting up a norm for productivity for a future period as budget, based on studies as above, and planning strategies to achieve it. Reasons for changes in productivity. Capital/labor ratio: It is a measure of whether enough investment is being made in plant, machinery, and tools to make effective use of labor hours. Scarcity of some resources: Resources such as energy, water and number of metals will create productivity problems. Work-force changes: Change in work-force effect productivity to a larger extent, because of the labor turnover. Innovations and technology: This is the major cause of increasing productivity. Regulatory effects: These impose substantial constraints on some firms, which lead to change in productivity. Bargaining power: Bargaining power of organized labor to command wage increases excess of output increases has had a detrimental effect on productivity. Managerial factors: Managerial factors are the ways an organization benefits from the unique planning and managerial skills of its manager. Quality of work life: It is a term that describes the organizational culture, and the extent to which it motivates and satisfies employees. International dimension of productivity: to remain competitive in the business. 1. Moving to a new and more advanced products, and 2. Employing better and more flexible system. Higher Standard of Living –Ability to increase productivity –Lower cost of goods and services Better Quality Goods and Services –Competition increases quality Improved Working Conditions –Better job design and employee participation 1. Define Operations management. Explain the key concepts of Operations management 2. Distinguish between manufacturing and service operation with example. 3. What is strategic planning? Explain the role of models in strategic planning. 4. Define the term operations management. Briefly explain the strategic role of operations. 5. Briefly explain how service producers differ from goods producers in important aspects of their operations. 8. State the important objectives of production management. 9. Define the term productive system. 10. Explain the concept of productivity. 1. 2. 3. 4. 5. Everett, E. Adam, Jr.Ronald J.Ebert, Production and Operations Management, Prentice-Hall of India Private Limited, 5th Edition, 1994. R. Pannerselvam, Production and Operations Management, Prentice-Hall of India Private Limited, 9th print, 2004. Joseph, G. Monks, Theory and Problems of Operations Management, Tata McGraw-Hill Publishing Company Limited, 2nd Edition, 2004. Joseph, G. Monks, Operations Management, McGraw-Hill International Edition, 3rd Edition. S. Anil Kumar, N. Suresh, Production and Operations Management, New Age International (P) Limited Publishers, 2nd Edition, 2008.

© Copyright 2026