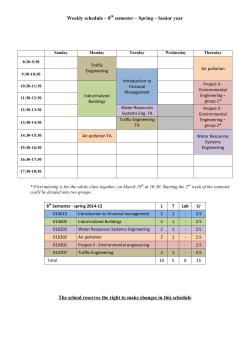

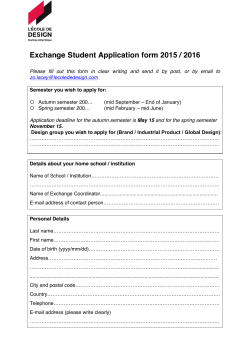

Faculty of Chemical Technology and Engineering 2015/2016