Counter Model Design Guide

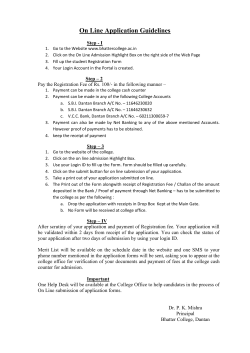

Counter Model Design Guide Tips on integrating your 32”D Structural Concepts under counter display case into a counter. The shape of the under counter display cases makes them ideal for integrating into counters so that all customers see is fresh food. These models are modular, and are designed to slide into/between counters. They include a self-contained refrigeration system in the base and a 6’ power cord for simple plug & play installation. Planning the space in the counter to accommodate the modular display takes careful consideration of key dimensions and ventilation requirements. To ensure a surprise free installation, the items in this guide should be addressed early in the design process. Structural Concepts under counter models are available in 32” & 24” depths. This guide is for the 32”D models. Models are available for under counter, counter height & freestanding applications. The under counter models (–UC suffix) are the ones that should be specified for building into counters. Table of Contents Installation Examples ……………. 2-3 Venting Requirements …………… 4 Counter Details …………………….. 5 Countertop & Electrical ………….. 6 Important Notes …………………… 7 Refrigerated under counter models are designed to integrate with counters when properly planned into the space. To avoid gaps like shown here, refer to the critical dimensions noted in this Design Guide. 2 The upper display is supplied by others. Countertop & front wall of counter extend over top board & end panels. 3 VENTING The design of the counter must allow proper air intake and discharge for the refrigeration system. The refrigeration system breathes in from the rear of the display. This area must remain completely open for proper air intake, as well as to provide access to the condensing unit for maintenance and service. The condensing unit slides out the rear of the display. Compressor air intake Counter Opening Keep area behind the display open for ventilation & condensing unit access. Warm air from the condensing unit is discharged out the front of the display at the toe kick. The toe kick in the front of the counter should match the toe kick on the equipment (Option 1). The toe kick is recessed 3 1/4” from the front panel and left open at the top to allow discharge of hot air. If this same design is not followed in the counter toe kick, vents are required to provide the square inch openings noted below. Also, if vents are part of the counter toe kick, the toe kick on the equipment must be removed (Option 2). Case Front Option 1 Option 2 4 Model Discharge Opening CO33R 109 in^2 CO43R 142 in^2 CO53R 178 in^2 CO63R 214 in^2 Toe kick on case is removed when customer supplied toe kick is provided with the counter. CRITICAL COUNTER DIMENSIONS The top board of the equipment is designed to be under the counter surface. The display equipment is supplied with recessed casters and a leveling leg next to it. The 32 3/4” AFF dimension provided is to the bottom of the caster. The leveling leg can drop down up to an additional 1” below the caster. Any adjustment to the leveling leg needs to be considered relative to the AFF dimension provided. The dimension to the top of the end panels is the same as the top board on the equipment. To front of display, not including the wall & with counter extended in front of top board 1/16” Inside of end panels Inside of end panels Counter 5 COUNTERTOP SURFACE Once the modular equipment is pushed into the opening in the counter, the counter surface can be positioned over the entire counter and display. In most installations, the counter surface extends over the end panels and the entire top board of the display. NOTE: The overall depth of the counter should be determined based on the 32 3/8” depth of the equipment and the depth of the front wall. To front of display, not including the wall & with counter extended in front of top board 1/16” Case Front Inside of end panels ELECTRICAL CONNECTION 6 A 6’ power cord is supplied and exits the display through the lower rear panel. See dimensions below. Refer to model specification sheet for electrical requirements and plug configuration. Important Items to Consider All food display cases are designed to operate in a controlled environment of 75°F and 55% relative humidity. Structural Concepts under counter models are designed to operate in higher ambient environments of 80° F. and 60% relative humidity. Keep in mind that energy management & smart thermostats can alter ambient conditions over a 24 hour period. Equipment designed to work in higher ambient conditions (noted above) is well equipped to perform in these environments. Even so, a pull down night curtain is recommended for non-operating hours. Where GFI is required by code, the display equipment must connect to a GFI breaker, not a GFI wall receptacle. The cycling of the compressor will trip a GFI wall receptacle. Avoid placing food display cases in locations near exterior doors, HVAC ceiling vents or where the display will be exposed to direct sunlight. These areas can cause issues with temperature performance. See illustration below as a typical example of how far to stay away from these areas. 7 For additional details on Structural Concepts refrigerated under counter models, refer to model specification sheets on the website. To build these types of models into counters, refer to the models with the -UC suffix. STRUCTURAL CONCEPTS CORPORATION 888 E. Porter Road Muskegon, MI 49441 t. 231.798.8888 f. 231.798.4960 w. www.structuralconcepts.com April 2015

© Copyright 2026