Methylamine Technology

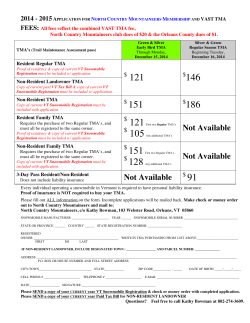

Methylamine Technology Background Davy Process Technology’s Methylamines technology originates in the 1960s with the Leonard Process Company of USA. We acquired the Amine technology rights in 2000 from Acid Amine Technologies. We have used our considerable expertise in developing new technologies towards the enhancement of this mature technology with particular emphasis on improved safety, reduction of fugitive emissions, reduction of effluents and improved product quality coupled with more cost effective design and reduced operating cost (feed and energy). Our position as the world’s leading licensor of methylamines technology has been demonstrated by the successful commercial operation of the latest world scale plant, demonstrating exceptional product quality for Methylamines. Our Amine Technology Portfolio includes: Methyl Amines (MA) Monomethylamine (MMA) Dimethylamine (DMA) Trimethylamine (TMA) Dimethylformamide (DMF) from DMA Choline Chloride (ChCl) from TMA N-Methyl-2-Pyrrolidone (NMP) from MMA We are confident that we can provide a professional tailormade Basic Engineering Package to enable a client to make a smooth transition to Detail Engineering. Methyl Amines (MA) Process MA Product Flexibility Methylamines are primarily used as intermediates in the production of pesticides, solvents, surfactants, and rubber processing chemicals. Methylamines are the major feedstock for the production of alkyl alkanolamines. They are also used in pharmaceuticals, explosives, agricultural and chemical markets, and water-treatment areas. Monomethylamine (MMA) Uses Mono methylamine is a feedstock for N-Methyl-Pyrrolidone (NMP) as well as for carbamate insecticides and surfactants. MMA is also used in the manufacture of Methyldiethanolamine (MDEA) for gas treating and for making Dimethylurea which is used for making synthetic caffeine. Dimethylamine (DMA) Uses Dimethylamine is mostly used for manufacturing Dimethylformamide (DMF) and Dimethylacetamide (DMAC) as well as detergents such as fatty amines and Lauryl Dimethylamine. Trimethylamine (TMA) Uses The major use of Trimethylamine is in the manufacture of the animal feed supplement, Choline Chloride. MA Process Schematic SYNTHESIS DISTILLATION Recycle PRODUCT STORAGE Lights Purge Monomethylamine A schematic flowsheet of our Methylamine process. (MMA) Anhydrous Dimethylamine (DMA) Trimethylamine Ammonia (TMA) Aqueous Methanol Waste Water Methylamines (MA) are produced by reacting ammonia with methanol at an elevated temperature in the presence of a catalyst. Most of the exothermic reaction heat is used in the feed heat recovery system. A mixture of three amines is formed, Monomethylamine (MMA), Dimethylamine (DMA) and Trimethylamine (TMA). They are separated and purified by distillation. By adjustment of the reactor feed ratio (methanol to ammonia) and recycling excess amines, the desired final product slate of Mono:Di:Tri methylamines can be achieved. By-product formation and degradation of the products to light ends is minimised by use of high quality raw material feedstock and state-of-the-art catalyst. A simplified set of the equilibrium chemical reactions for the formation of mono, di and trimethylamine are shown right. The reverse reactions of amines to form other amines occurs by a set of Disproportionation or Transmethylation reactions as shown below: 2CH3NH2 2MMA (CH3)2NH + NH3 DMA 2(CH3)2NH 2DMA CH3NH2 + (CH3)3N MMA + TMA (CH3)3N + NH3 TMA + Ammonia CH3NH2 + (CH3)2NH MMA + DMA CH3OH + NH3 Methanol + Ammonia CH3NH2 + H2O MMA + Water CH3OH + CH3NH2 Methanol + MMA (CH3)2NH + H2O DMA CH3OH + (CH3)2TNH (CH3)3N + H2O Methanol + DMA TMA Crude MA product is purified by firstly separation and recycle to synthesis of excess ammonia. Extractive distillation using recycled water produces pure anhydrous TMA, followed by water separation to produce a water free MMA/DMA mix, which is then separated into pure anhydrous MMA and DMA. Methanol recovery is used to improve process efficiency and extend catalyst life by allowing greater methanol slip from the synthesis section. Anhydrous MMA, DMA and TMA can be diluted with water to produce aqueous product solutions. MA Commercial Status Our Methylamine plants are of world scale capacity varying in size from 8,800 to 50,000 tonnes per year of mixed methylamines. MA Process Benefits Davy Process Technology’s Methylamine Technology builds on an established process that has been commercially operated for over 50 years and offers the following features: Most extensively licensed process in the world. Proven and reliable design produces class leader product qualities. Large capacities available in a single train. Highly flexible technology allows plant to be designed to give optimal product slates with the ability to be adjusted online to match future requirements. Highly efficient, high activity and low by-product catalyst. Optimised heat integration for improved efficiency and reduced operating costs. Low environmental impact including numerous features to prevent atmospheric emissions. For further details please contact: Davy Process Technology 10 Eastbourne Terrace London W2 6LG UK Tel: Fax: Mail: Web: +44 (0)20 7957 4120 +44 (0)20 7957 3535 [email protected] www.davyprotech.com Davy Process Technology is a Johnson Matthey company.

© Copyright 2026