Invitation LIGNA 2015 - Homag Group eXtranet

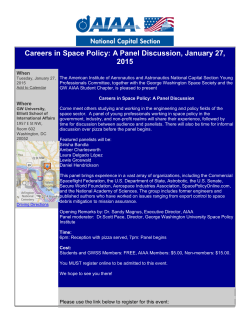

INVITATION LIGNA 2015 We would like to invite you to the LIGNA, taking place from May 11 - 15 in Hanover. As a leading manufacturer of high performance machines and lines for timber construction, WEINMANN has developed innovative and practical solutions for your success. Carpenters as well as manufacturers of prefabricated houses worldwide successfully use WEINMANN systems. At the Ligna, we are going to present you the latest developments in the field of machine technology for timber construction – come and watch our live demos: •Carpentry Machine WBZ 160 powerSIX - processing of all 6 sides without beam tilting •Panel Production Line compactPLUS - flexible and efficient production of wall, roof and gable elements •Assembly Tables for every requirement - production of frame works, creation of roof panels, Invitation LIGNA processing of solid wood elements •All-rounder WMS - from frame work production to panel cutting to solid wood processing You will also receive a lot of information about the new applications in the field of fully-automatic panel cutting with the multifunction bridge. Find out more about the WEINMANN solid wood portal, which is the only solution for machining of multi-layer solid wood and timber frame elements on the market. On the occasion of this year’s anniversary, we would like to offer three edition machines to you: •Panel Production Line compactPLUS: 30 %increased productivity •Carpentry Machine WBZ 160 powerSIX: 30 % inreased efficiency MANN of WEIN rs e a e y 0 3 ormanc her perf 30 % hig •Butterfly Turning Table: 30 % time saving Visit us and let us advise you on site by our specialists. We look forward to seeing you at our stand no. C 23 in hall 15. Your WEINMANN team WEINMANN News y 2015 th of Ma 11th - 15 no. C23 5, stand 1 ll a h in Visit us •Flexible and efficient panel production •Beam processing technology - processing from 6 sides without tilting •Solid wood processing •Fully automated panel cutting Here you can learn more about our A company of the HOMAG Group edition machines: www.weinmann-partner.de Or simply scan the QR code: WEINMANN Holzbausystemtechnik GmbH Forchenstraße 50 72813 St. Johann - Lonsingen Tel. +49 7122 8294 0 [email protected] www.weinmann-partner.com www.youtube.com/WeinmannHolzbau WEINMANN beam processing technology – designed for precision WEINMANN element manufacturingGreater flexibility through automation By means of WEINMANN carpentry machines you are able to perform all cutting and joining work quickly and accurately. From fast cutting to complex joinery, these machines cover a wide range of tasks. The high degree of prefabrication is becoming increasingly important in element manufacturing. The advantages are obvious: a more cost-efficient production plus consistently high quality. Moreover, you will reach the highest processing accuracy with WEINMANN beam processing technology. Thus, the components on the site can be installed quickly, cleanly and easily. Your advantages: WEINMANN assembly tables offer you simple and ergonomic production of high-quality timber frame elements. With the butterfly turner you get a proven solution for fast and safe turning, which is estimated by timber companies worldwide, because it is comfortable and ergonomic. With a multifunction bridge you will benefit twice. With this machine, you will increase the productivity and accuracy in your production. Requiring just a minimum of space! •Profitable within a very short time •Highest accuracy •Efficient production •Space-saving installation Your advantages: • Ergonomic working • Time savings • High flexibility •Precise elements Processing of all six sides - More flexibility in beam processing through WBZ 160 powerSIX The newly developed underfloor unit enables even more flexible beam processing. Equipped with a 6,6 kW drive for disc router, plus a 7,5 kW drive for finger router, dove tail router or drills, machining tasks like classic block house joints, dovetail connections on both sides on purlins, as well as blocking grooves on ridge beams can be created easily. This not only allows a higher level of precision to be achieved, but also offers a great variety of applications and simplifies handling. achine entry M rp a C : W NE IX 0 powerS WBZ 16 One machine, lots of functions Once again the WMS gives proof of its versatility The basic version of the multifunction bridge shows already the great versatilitiy of this machine. Moreover the WMS can be used for additional works: Panel production line compactPLUS: Equipped with a unit for frame work generation, also frame works can be created semi-automatically. What’s more, the multifunction bridge now also enables fully automated panel cutting plus the full nesting functionality. Main functions: •clamping and nailing •sawing, routing and drilling •marking and labelling Additional functions: •gluing •screwing •panel cutting •production of a frame work •processing of solid wood on line ucti nel prod NEW: Pa S LU compactP

© Copyright 2026