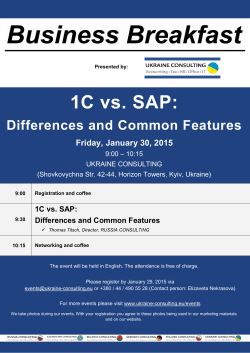

Coffee services