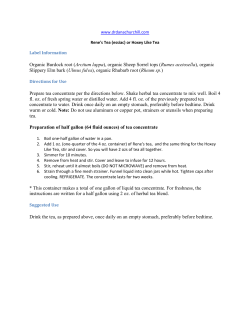

Document 161945