Business in the 21st Century – 2011 / Issue 01

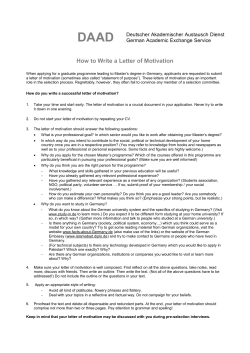

The Ingenics Customer Magazine 2011 / Issue 01 Business in the 21st Century – How to Navigate the Economy’s Roller Coaster Most importantly, you will have to look at quality, and make sure it stays top-notch - in your products, in your procedures, and in the interaction between your processes and your people. After all, the fundamental issue is to empower and motivate your existing employees to increase their value creation. In the short run, this will help you to rapidly increase production as needed, allowing you to always perfectly meet fluctuating demand. And over the long term, synchronizing people and processes will help you overcome issues with personnel, including a decline in skilled labor, demographic workforce changes, and more – which we’re already noticing in a wide range of industries. So far, we’re only seeing the tip of the iceberg. More is yet to come. But for Ingenics, the emerging trend is motivation enough to examine its reasons and offer solutions. The fact is, adapting processes to people is becoming ever more important. And that’s exactly what Ingenics Dear Reader, As the global economy continues to go through its ups and downs, companies are re-evaluating their strategies, looking closely at how they can do more with less in order to stay afloat no matter what the economic climate. For these companies, their main concern is how to optimize the relation- specializes in. True to our credo, “designing systems and enabling people,” our multi-functional industrial consultants offer end-to-end services, simultaneously focusing on people and processes to help you accomplish more with fewer resources - and achieve not only rapid, but also lasting success. Read on to see how our solutions are helping companies all over the world. Enjoy! ship between resources and output. The answer is simple: it’s all about increasing efficiency. But how? Don’t worry! You won’t necessarily have to invest in new facilities and new equipment to achieve this goal. But you will have to pay close attention to several key factors. Oliver Herkommer Managing Partner Jörg Herkommer Managing Partner content ·LeanOffice: Exceptional Space for Extraordinary Solutions · ERP Solution in Record Time · The Latest from the US: Mastering the Challenge of Economic Growth · Happenings in China: BMW Launches New Plant in China in Seven Months · Book Review 2011 / Issue 01 Exceptional Space for Extraordinary Solutions New Ingenics Offices in Hamburg – Stylish. Streamlined. Lean. We’ve recently opened a new office in Hamburg. Situated at the Atlantic Haus, it offers a breathtaking 360-degree view of the city. But what’s truly impressive about the space is that it serves as a convincing real-world model for the power of office optimization – thanks to its modern office concept, sophisticated workplace design, and consistent implementation of LeanOffice principles. When maximizing efficiency for the new space, Change of Perspective we first focused on the basic floor design. on adding value - and no single person must times or staff changes. How? By using One organization. Free from mental and physical take charge of ordering processes; all have Point Lessons that answer the most frequent- distractions, employees are able to use their Employees need take only a few steps from The kind of quality solutions that Ingenics more time to create value. Employees can ly asked questions, succinctly, in clear visuals optimized work space to focus on what really their workstation to access frequently used customers have come to expect require neit- use their spare time and dips in concen- placed directly where the questions arise. matters – creating value, and developing equipment and materials. Conference rooms her stereotypical environments nor creative tration to process the data collected in the and other public areas are strategically po- chaos, but rather the systematic promotion Kanban boxes, following easy and clear Similarly, cabinet visualization ensures a sitioned by the front entrance, allowing of various perspectives. That’s why we have directions. By shifting the Kanban card, they seamless, efficient workflow. Even rarely visitors to enter without interrupting the built creative spaces in variable sizes, decora- signal that the process is in progress. It’s used documents and materials can be instant- regular work routine. But the real impact ted with eclectic furniture in exciting colors only a small step for the individual, but it is ly accessed and properly filed back after use. comes into play when we look into the heart that allow for a quick change of scenery, and a big help for the office community. Work At Ingenics in Hamburg, 5S is no longer an Our new office in Hamburg is not only a of the operation – the offices themselves. help people unwind and keep their minds times are used more efficiently, and mate- abstract ideal, but rather a practical stan- place where we develop top quality solutions fresh throughout the workday. rial shortages as a result of the person in dard that is reinforced during regular audits. for our clients. It is also a training facility charge being sick or on holiday are a thing In the office environment, just as in pro- where we teach lean methods to up to 20 of the past. duction, proven standards are the best participants at a time. Feel free to call us Built-in Efficiency As for the interior design, we’ve relied on Many companies wonder what’s better: an professional advice. All of our equipment open-plan space or individual cubicles. Our meets the requirements of the latest ergo- answer may sound paradoxical, but the most nomic standards, and sets the stage for efficient solution is actually a combination maximum staff performance. of both. Why? Because office work is multi- the best solutions for their customers’ busi- breeding ground for a continuous improve- to schedule a training session, or for a tour ment process. of our facilities. Can’t make it in person? Another example that shows that small steps A rules round is also part of everyday life taste of how this ingenious approach can work in your office environment. Download this handy Kanban Card to get a go a long way: Ingenics’ One Point Lessons. at Ingenics, eliminating problems before Finally, we’ve designed and implemented In our Hamburg office, questions like: “How they even arise and promoting a lean spirit “As much as necessary, as little as possible:” One times of communication require different intelligent processes facilitated by transpa- does the copier work” or “How do I use the throughout the organization. Point Lessons, the central Kanban station, uni- environments; and because compromising on rent, powerful tools to ensure that workdays flip chart” never even come up. No one in our Hamburg office produce maximum wastes time looking for the answer or asking and perfect order in the file cabinets – Ingenics Hamburg is a truly lean office environment. either one yields poor results in both. That’s why we’ve allocated a large portion of the value. office space to include silent as well as creative and communicative work islands, with Secure Processes additional silent offices situated just across the hall - providing perfect silos for any A case in point: the Kanban system. Guaran- situation. And since personal items are stored teeing “just-in-time” part supply in produc- in a central location in easily accessible, uni- tion, Kanban also yields numerous benefits in formly labelled boxes, employees can always office environments. No single person needs choose the silo that best fits their needs. to keep track of material orders; all can focus Come and See for Yourself Keep it Simple faceted; because times of concentration and form boxes for consultants’ personal documents, ness success. KANBAN Artikel: Ultimately, all of these concepts in practice colleagues for help. Instead, everyone’s build the foundation for the final element permanently in control, even during holiday of Ingenics’ Lean Office system: staff self- for Lean Office Ingenics Tools an Card Processes: Kanb for free at Download now om/Kanban .c cs www.ingeni Mindestbestand: Optimale Bestellmenge: ProduKtiNf ormAtioNeN Artikelbeschreibung: Lieferant: Bestellnummer: Zusätzliche Informationen : www.ingenics.de 2011 / Issue 01 Process Analysis and Optimization Ensures Success Ingenics at JEOL Germany: Selecting and Implementing an ERP Solution in Record Time The successful deployment of a new IT system depends not only on the software purchased, but also on the selection process. And in fact, a process-oriented approach is critical to helping companies select the most appropriate solution, introduce it in the most efficient manner, enable continuous improvement, and ensure lasting success. Many companies struggle with a similar prob- minimize the risk of spending time and ener- process optimization. Once exact require- lem on the IT front: The need to focus on the gy on a solution that would ultimately prove ments are determined, this process-oriented day-to-day business leads to the introduction lacking. That’s why we turned to a third-party approach helps to align the features available of one partial upgrade after another, causing expert to help us make the right decision: in various ERP systems to these requirements. them to increasingly lose sight of the big Ingenics.” All this can be done without disrupting picture. As a result, they typically end up with ongoing operations. isolated and often incompatible solutions. But The Difference: Process-Oriented System this can all be avoided with the right approach. Selection Coming to America: Mastering the Challenge of Economic Growth Ingenics’ cross-cultural competencies can help companies quickly ramp up production capabilities, without breaking the bank. After identifying the best solution, Ingenics A case in point: JEOL Germany. business unit manager Heiko Finn and his With the economy continuing to recover, workplace trends – specialists like Ingenics. challenging tasks. In the production environ- What makes Ingenics a valuable partner for team help companies to negotiate the con- the American market presents a wide range With proven expertise in both German and US ment, for instance, clearly defined TAKT times The German subsidiary of a Japanese manu- ERP selection? For one thing: expertise. tract and implement the system. This ensures of business opportunities for German manu- manufacturing operations, Ingenics provides and additional visualization enable route train facturer of scientific equipment, JEOL Germany Ingenics´ specialists tap into an in-depth a seamless deployment that is perfectly in sync facturers. But even as they ramp up pro- them with the insight and support they need conductors to rapidly master their jobs, even had long since planned to introduce a new knowledge of the ERP marketplace, making with customer needs, from start to finish. duction facilities across the US, German to improve efficiencies across multiple inter- without prior work experience. ERP system to better support its specific re- it easier to quickly and effectively zero in companies face a common challenge: how national locations, effectively and affordably. quirements. When the company was put in on the systems that are best suited for each At JEOL, the early results are promising. Thanks to continue to leverage their existing How? By enabling them to first analyze the Once all processes are properly designed, charge of the JEOL subsidiary in Stockholm, company’s needs. to the new ERP system, the company’s sales methods within an entirely different cor- status quo and understand its underlying professional training is the icing on the cake, process has become greatly streamlined – a the timing was ripe to put the wheels in porate culture. Increasingly they are turning workings, then systematically identifying and driving acceptance across all departments – motion. "With several locations involved, we But there is another reason why working critical edge in an industry where large pro- to Ingenics, whose proven cross-cultural applying those elements that are responsible from top management to shop floor person- had to find a way to map out all processes with Ingenics proves so beneficial. When our jects usually take years to complete. Controll- competencies and unique lean consulting for long-term success. nel – and ensuring lasting results. Such train- and their interaction so we could find a so- specialists first develop the specs for a new ing has also been significantly improved. With approach have enabled hundreds of com- lution that leveraged existing synergies, yet system, using a detailed checklist, they also Ingenics’ help, the entire project ran smoothly panies to effectively apply global practices effectively met all needs," explained CEO engage in a comprehensive process analysis – and to perfection, and is well on track to at the local level to achieve success. Dr. Siegfried Falch. “Of course, we wanted to setting the stage for professional, integrated yielding a rapid and lasting ROI. Module 1 Phasen Activities Foundation Define Project Goals and Prerequisites Customize Implementation Approach Strategic Evaluation Define: Methods Coordinate Organizational Administration & Communications Organizational Evaluation • Assess Status • Corporate Goals • Define Target Processes • Core Competencies • Develop Specs • Technology Needs • Check IT • Market Demands • Check Site Define Project Scope Objectives Module 2 Shortlist Final Selection Implementation • Research Available • Develop RFQ Solutions and • Finalize Cost Data Validation Estimates • Consolidate Results • Fine Tune Implementation Plan • Plan Data Transfer and Set-Up • Conduct Testing & Assessment • Develop Training Concept • Contact • Provide RecomSolution Providers mendation • Manage Integration • Present Options • Manage Contract of Subsidiaries Negotiations • Select Top Two Choices • Complete Project Market Research 200 Systems on the Market 10-15 Systems 3-5 Systems Decision & Contract System Selection Process Modeling Project Management Duration Module 3 9 to 15 months Adaptation JEOL Germany develops electron optical equipment and instruments for scientific and industrial research including electron microscopes (SEMs and TEMs). ing requires coaches who offer an industry First Understand, then Act Accordingly insider’s experience while keeping an eye on the big picture, understanding the needs of Let’s look at staff training as an example. both the headquarters and its local subsidia- When it comes to international business, the With employee turnover rates typically ries, and combining lean manufacturing con- usual rules don’t always apply. What works higher in the US than in Germany, Ingenics sulting expertise with cross cultural know how. in one country doesn’t necessarily work in helps German manufacturers adapt and acce- These are the types of trainers and lean con- another. Yet global businesses must have stan- lerate their job orientation practices accordin- sultants you can find at Ingenics in Atlanta. dardized practices in place to increase effi- gly. However, bringing new personnel rapidly To find out how you can benefit from our ciencies across the board, while keeping costs up to speed does not have to mean straying industrial engineering consulting services in at bay. Finding the right balance between from the systematic work methods and high the US, contact us today. global directives and local requirements is quality standards for which Germany compa- 2839 Paces Ferry Road key. That’s why many German companies nies have become famous. With well-defined, Suite 1045, Atlanta, GA 30339 coming to the US are now turning to outside simply structured, properly documented, and Phone +1 678 528-7042 specialists who are as familiar with German transparent processes, new employees in the [email protected] engineering practices as they are with US US can quickly learn to master even the most www.ingenics.com 2011 / Issue 01 As Markets Set the Pace, Companies Turn to Unconventional Solutions to Charge Ahead 市场需求决定企业发展速度,各公司突破常规方案,共同开拓进取 BMW Launches New Plant in China in Seven Months 宝马七个月内将在中国开设新厂 With demand for German cars at an all time high in China, German car manufacturers are racing to ramp up their local production capabilities while keeping their budgets under control - charging ahead, while keeping a light foot on the brake. BMW is one company that has successfully risen to the challenge, staying true to the motto “Think outside the box.” 由于中国市场对德国汽车的需求创历史新高,德国各大汽车制造商正卯足劲扩大各自在中国的产能,而与此同时还要严格控制 预算支出——高速前进时不忘轻踩刹车。宝马公司本着“解放思想,突破常规”的理念,成功应对挑战,成为同行中的佼佼者。 Though BMW already had plans to move to a Together, BMW and Ingenics focused on: plan- which the collaboration between all parties house structure including incoming parts; and other global clients, Ingenics is available new plant in China for the production of its ning streamlined processes; defining staff, involved, including BMW headquarters, the setting up special cargo carriers for kitting; to help manufacturers around the world real- next model, local demand was rapidly gro- equipment, and structural building needs; joint venture BMW Brilliance Automotive and, last but not least, efficiently bridging the ize even their most ambitious expansion plans. wing for its current 3Series, making it neces- developing individual training concepts to Ltd., BMW’s SAP experts from South Africa, open spaces between the four facilities. sary for the company to increase manufac- adequately prepare local staff for the tasks and various external partners, needed to work turing capacities immediately. The situation ahead; monitoring the implementation; and to perfection. Seven months during which Despite these challenges, BMW was able to called for an interim site, one that could be finally, supporting the launch. The project re- Ingenics’ logistics experts were required to successfully reach its ambitious project mile- completed within just seven months. To meet quired maximum performance at every level, be on site around the clock. Seven months stones in record time. How? By leveraging this aggressive goal - and plan the logistics while balancing seamless adaptation to local during which seamless communication flexible, low-cost concepts, implemented in layout and processes for production from the requirements and conditions. While these may between all project members was required - strict compliance with lean philosophies, and arrival of ready-to-install parts to the final have seemed like routine tasks for BMW’s since every little misunderstanding, any minor by keeping the project pace high and spend- assembly - BMW called on a trusted partner experts and Ingenics’ logistics planner, the delay would have jeopardized the timing and ing low. with proven experience in the Chinese mar- companies also faced some unique challenges success of the entire operation. ketplace: Ingenics. along the way. For example: the new processes Simply Lean had to be synchronized with the plant layout “This was certainly one of the most uncon- of a site that was already selected and rented, ventional tasks I’ve ever faced,” admits Dr. Today, BMW’s interim production site sports encompassing four hangars in an existing Jens Nitsche, Ingenics Partner and head of two logistics and two assembly halls, each al- industrial park. In addition, spending had to the Ingenics team for this project. “But since lowing for seamless expansion as needed. Best be kept to a minimum. Substantially changing BMW laid the groundwork, we could proceed practices are at play throughout the facility. the existing architecture was out of the without delay.” For instance, Kanban-scheduled route trains feature flow racks that enable highly effi- question for an interim site. As a result, the processes had to be designed to adapt both in According to Nitsche, proven methods and cient supply to the entire assembly plant. Many time and in space to existing physical conditi- best practices always need to be adapted to other flexible, low-cost concepts have been im- ons, which were less than optimal. the specifics of each project, but the neces- plemented in accordance with lean principles. sary changes are rarely as complex as for this Ramping Up Resources Just-in-Time particular endeavour. Key tasks included: line The BMW project is a great example of how side planning; conceiving material delivery; manufacturers can ramp up to deliver a top The companies had only seven months from creating kitting and sequencing areas; timing quality product in record time, without high project start to finish. Seven months during and placing route trains; planning the ware- costs. Tapping into its experience with BMW 虽然宝马已经决定在中国开设新工厂生产其新 车型,但中国当地对宝马3系的需求增长迅速, 因此提升产能势在必行且迫在眉睫。要在短短七 个月内完成产能扩张,只能选择临时厂房。为科 学规划物流布局和包括零部件运输与组装在内的 生产流程,同时完成扩张目标,宝马选择在中 国市场具有实战经验且值得信赖的英见公司作为 合作伙伴。 合作伊始,双方共同致力于:规划先进的生产流 程,置办生产设备,遴选厂房;招聘高素质本地 员工并进行宝马独特的企业文化培训,使其足以 胜任工作岗位;全程监督各项工作的进展,确保 整个目标的实现。整个项目的完成有赖于各方面 的全力以赴,包括参与者入乡随俗、因地制宜、 物尽所用、人尽其才。上述任务对于这支由宝马 专家和英见物流规划精英组成的合作团队自是驾 轻就熟,然而挑战不仅限于此。例如:生产线的 建设必须与厂房规划同步。由于已经选定并租下 工业园区一处带有四个大仓库的厂房作为厂址, 为使支出最小化,不可能对现有厂房结构进行 大规模的改动。因此,生产线的设计就必须立 足实际,在项目时间和现有空间两方面都做出 相应调整。 汇聚力量、及时高效 从项目的启动到落成,合作双方只有短短七个月 的时间。在此期间,包括宝马总部、中德合资华 晨宝马有限公司、来自南非的宝马SAP系统专家 以及其他参与此项目的合作者必须通力合作,力 臻完美;在此期间,英见的物流专家必须随时待 命,确保全天候的服务;在此期间,所有项目参 与者必须实现无障碍沟通交流,因为任何看似不 起眼的沟通失误和短暂延迟都会影响整个工程按 时保质地完成。英见合伙人、参与本次项目合作 的领队Jens Nitsche博士认为:“这是我所参与过 的最不同寻常的项目之一;鉴于宝马公司已经打 好基础,我们应该争分夺秒,勇往直前。” 博士认为,尽管实证理论和最优方法必须与实际 情况相结合,但这个项目所作的针对性调整的复 杂程度是罕见的。关键任务包括:规划生产线、 构思原材料输送、设立配套装配及顺序排列区 域、调试并安装输送流水线、以发展的思路规划 仓库结构、为配套装配提供专用运货工具;最 后,有效利用四座厂房之间的空间。面对众多挑 战,宝马公司还是按时保质完成了其里程碑式的 扩张项目。原因何在?严格落实精益生产,灵 活多变、低投入、高产出,确保整个工程进展 快、成本低。 精益生产、大道至简 如今,宝马的临时生产线由两个物流供给线和两 个组装线组成,每条生产线皆可根据需要进行无 缝扩展。各种先进技术和操作规范贯穿整个生产 流程。例如,基于看板系统制定的输送流水线给 整个组装线提供了高效支持;其它灵活多变的、 低成本的做法淋漓尽致地体现了精益生产的理 念。宝马公司的这个项目是制造商追求短时间、 低成本、高质量运营的经典范例。经过与宝马以 及其他全球客户的成功合作,英见公司愿全力协 助全球制造商开拓进取,大展宏图。 2011 / Issue 01 Book Review "Too Big to Fail". By Andrew Ross Sorkin Too Big to Fail: The Inside Story of How Wall Street and Washington Fought to Save the Financial System – and Themselves. Perhaps nobody understands the impact of the recent recession better As an acclaimed reporter at one of the world’s than manufacturers. In the wake of the crisis they have been working tire- premier newspapers, Sorkin was able to interview lessly to restructure their businesses to become leaner and better prepared many policymakers as well as key players at the Wall Street banks for any economic scenario. But what led to the downturn, and could we whose actions contributed to the fall of the economy. The result is a have spotted early warning signs? New York Times reporter Andrew Ross startling look behind-the-scenes at the relationship between the country’s Sorkin seeks to answer these questions revealing the true stories behind financial institutions and its government. Sorkin has kept most editorial the recent financial collapse in the United States – a fascinating read for opinion out of the story to offer a thorough chronology and compelling in- all who were affected by it. side look at a situation that some have said “reads like a fictional spy novel.” The 11th Ulm Dialogues – May 26 2011, City Hall, Ulm, Germany Visions, Strategies, and Methods to Shape the Future: Addressing Demographic Changes in Your Business. The prospect of exciting presentations, stimulating discussions, and valuable insights always turns our annual Ulm Dialogues event into a popular meeting place for international decision makers. This year, we address the growing challenge of integrating a changing workforce. The topic: Demographic Changes in the Workplace – Breaking Down the Hype: How Companies Can Prepare for the New Reality of Business When it comes to aging workers, less skilled workers entering the market, and other demographic changes to today’s labor force, everyone has something to say – whether it’s making the situation sound dire, or completely downplaying it. Ingenics experts and renowned speakers will discuss the changing workforce that often raises controversial yet rarely productive dialogue. Our program will include a thorough theoretical and strategic analysis of this emerging trend. TV anchor Peter Hahne will give the keynote address. And as always, all our presentations promise to be clear, concise, newsworthy, entertaining, and informative. To receive your personal invitation, please contact Selina Berendorf at Ulm Dialogues 2011: Peter Hahne Expected to Keynote +49 731 93680-211 News Ingenics is growing! We’ve expanded our training facilities in Hamburg and Shanghai, and we’ve opened a brand new office in Paris. True to our commitment to be available wherever you are, our larger presence allows us to offer consistent industrial engineering consulting services and reliable quality across all your global facilities. For a list of our offices around the world, please visit our new website: www.ingenics.com Contact information inGenics Corporation · 2839 Paces Ferry Road · Suite 1045 · Atlanta, GA 30339 [email protected] · www.ingenics.com · Phone +1 678 528-7042 · Fax 261-8699 Ulm · Stuttgart · Munich · Hamburg · Paris · Shanghai · Atlanta

© Copyright 2026