Document 189923

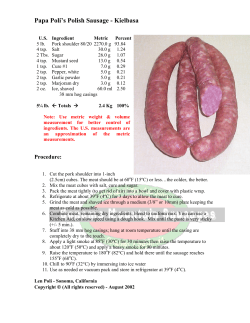

we are e x p e r t s in e m u l s i f i e r s and stabilizers for bakery, confectionery, dairy, ice cream, margarine and fine foods - and we happy to share our expertise. our company values can be defined are in just three words : loyalty, responsibility and we aim to be the preferred partner commitment. and supplier of quality products, application service and knowhow to regional and m u l t i - n a t i o n a l food companies. to Palsgaard l o y a l t y means that we act as a reliable and honourable business partner for our customers. we treat information confidentially and know how to keep a business secret. to Palsgaard r e s p o n s i b i l i t y means caring about the environment and being aware of our corporate social responsibility; we have a goal to be CO 2 neutral by 2020 and are members of SEDEX and RSPO. to Palsgaard c o m m i t m e n t means we are dedicated to getting the best results for our customers’ products - to the benefit of their customers. we care about our employees and have a declared aim that Palsgaard must be a pleasant place to work. Palsgaard we know that our most important resource is the k n o w - h o w and d e d i c a t i o n found in our employees. we are committed to getting the best results with our products in our pilot plants and in your facilities. at Palsgaard we don’t sell standard solutions - we start with your needs. Palsgaard - Heart Working heart work is the best way to achieve success - let us help you get it. our products are produced according to the Heart Working People strictest quality criteria. we are experts in emulsifiers and stabilizers and we are happy to share our expertise with you. let our pilot plants help you shorten the step between idea and your new product. heart work is the best How to improve the quality and reduce the costs of meat products by using emulsifiers Palsgaard Technical Paper, September 2010 way to succeed - let us help you do so. By Cai Clemen Christensen, Business Unit Manager, Lipid & Fine Food Group Palsgaard A/S. The use of emulsifiers in meat product manufacturing A meat batter is a fat in water dispersion, with properties resembling an oil-in-water emulsion. Emulsions are thermodynamically unstable systems that need stabilization by emulsifiers, stabilizers or combinations of both. The emulsifiers already in the batter are the meat proteins which are activated by use of phosphates, sodium chloride and shear force. The stabilizers already in the batter are collagen/ gelatine. Over many years several new types of emulsifiers for use in meat products have been developed. In the following, the use of Palsgaard emulsifiers in sausages and patées will be discussed. It is a well known fact that food manufacturers wish to improve the quality of their products. They do, however, also wish to reduce the costs of their products in order to become more competitive in the market. For meat product manufacturers the use of emulsifiers can make both wishes come true. This paper describes the effects of emulsifiers in both frankfurter sausages, liver sausages and patées. Table 1: List of Palsgaard emulsifiers for meat products. They may be used alone or in combinations for creating a stable emulsion in the meat product. Product name E-number Palsgaard® Citrem 3302 E- 472 c Citric acid esters of mono- and diglycerides of fatty acids Palsgaard® Citrem 3307 E- 472 c Citric acid esters of mono- and diglycerides of fatty acids Palsgaard® 3327 E - 471 and E - 472 c Citric acid esters of mono- and diglycerides + mono- and diglycerides of fatty acids Palsgaard® DMG 0090 E - 471 Distilled mono- and diglycerides of fatty acids Palsgaard® DMG 0093 E - 471 Distilled mono- and diglycerides of fatty acids Palsgaard® MDG 0038 E - 471 Mono- and diglycerides of fatty acids Palsgaard® MDG 0054 E - 471 Mono- and diglycerides of fatty acids all produced under cold conditions ( 0 – 13oC ). Emulsifiers are surface active molecules and examples are proteins, phosphor-lipids and monoand diglycerides of fattty acids and esters of these. This article will focus on the use of the last mentioned group, and the emulsifiers listed in table 1 and illustrated in figure 1 are used alone or in combinations in sausages and patées. Sausages made from cold processed meat emulsions We will first discuss the use of emulsifiers in frankfurters, wieners, hotdog sausages, bolognas and mortadella types, which are Type of emulsifier The sausages are all based on a meat emulsion (a suspension of fat particles in a gellified meat and water phase) and they are all stuffed in suitable casings. Figure 1: Palsgaard emulsifier for meat products. For these types of sausages we will mainly recommend the use of Palsgaard® Citrem 3302 and Palsgaard® Citrem 3307. In order to illustrate the functionality of the emulsifiers, trials with Palsgaard® Citrem 3307 (E472c) in frankfurter sausages were performed. Palsgaard Technical Paper - September 2010 How to improve the quality and reduce the costs of meat products by using emulsifiers 2 Palsgaard® Citrem 3302 Palsgaard® Citrem 3307 Frankfurter sausages Wiener sausage Bologna Palsgaard® Citrem 3327 Palsgaard® DMG 0093 Palsgaard® DMG 0090 Palsgaard® 0054 Palsgaard® 0038 Retorted liver pâté Fine liver sausage Table 2: Overview of Palsgaard’s product range for use in sausage products. In table 3 the test system is described and in figure 2 the process is illustrated. Frankfurters with 0.3 % dextrose, 0.3 % casinate or 0.3 Palsgaard® Citrem 3307 were produced. Figure 2: The manufacturing process of the frankfurter sausages used in this trial. Minced meat, Phosphate, salt Palsgaard® Citrem 3307 Cut for 30 seconds at high speed Cool sausages and store at temperature = 5oC 2/3 ice water, dextrose, ascorbic acid, seasoning Cut to temperature = 5oC Cook sausages in stam to core temperature = 70oC 1/3 ice water, minced fat, starch, soy isolate Cut to temperature = 13oC Smoke sausages for 60 minutes Temperature = 65oC Fill batter into casings Dry sausages at low RH. Temperature = 60oC Table 3: Recipe suggestion for frankfurter sausages Ingredient Mass % Beef III (18 - 20 %) 10.20 Pork II (12 - 12 %) 38.80 Pork backfat 22.00 Ice water 23.30 Nitrite curing salt 1.60 Dextrose 0.20 Ascorbic acid 0.05 Phosphate 0.25 Starch 1.00 Soy isolate 1.80 Palsgaard Citrem 3307 0.30 ® Seasoning Sum 0.50 100 % Palsgaard Technical Paper - September 2010 How to improve the quality and reduce the costs of meat products by using emulsifiers 3 In order to evaluate the functionality of Palsgaard® Citrem 3307 in the produced sausages the purge loss and the cooking loss were measured, and as shown in figure 3, a clear difference can be observed. The cost factor is always important, and 2 different frankfurter sausages were produced; with and without Palsgaard® Citrem 3307. The recipes are listed in table 4. Based on our raw material cost information, we calculated a cost reduction of up to 5 % in the frankfurter with Palsgaard® Citrem 3307, because of the increased use of pork backfat and water addition and less Pork II with 10 – 12 % fat content. By using Palsgaard emulsifiers in sausages we obtained: • A very good dispersibility in the meat batters, processed under cold conditions • Stable emulsions also in products with high fat and water content • Reduction of purge loss and cooking loss • High quality of the produced sausages • Possible to optimize the cost profile of the sausages • Flexibility in raw material selection 7 days 14 days 28 days 0.3 % Dextrose 0.3 % Caseinate 0.3 % Palsgaard® Citrem 3307 Figure 3: The diagramme on the left shows the purge loss % during vacuum storage and the diagramme on the right shows the cooking loss %. Ingredient Sausage 1 Sausage 2 Beef III (18 - 20 %) 10.20 10.20 Pork II (10 - 12 %) 40.80 36.80 Pork backfat 20.00 22.00 Ice water 23.30 25.30 Nitrite curing salt 1.60 1.60 Dextrose 0.30 0.30 Ascorbic acid 0.05 0.05 Phosphate 0.25 0.25 Starch 1.00 1.00 Soy isolate 2.00 1.70 Palsgaard® Citrem 3307 0.00 0.30 Seasoning Sum 0.50 0.50 100 % 100 % Table 4: Recipes of two different frankfurters with and without Palsgaard® Citrem 3307. Warm processed emulsified meat products This group includes the products liver patées and liver sausages and are produced by using a hot process ( 50oC – 80oC ). The products are packed in casings or in cans. For these products a wide range of the emulsifiers from Palsgaard can be used; please look at table 5. As for frankfurter sausages we have chosen a test system for these types of products: Liver sausages and as emulsifier we have selected Palsgaard® DMG 0090, which is a distilled monoglyceride Palsgaard Technical Paper - September 2010 How to improve the quality and reduce the costs of meat products by using emulsifiers 4 Table 5: Overview of Palsgaard’s product range for use in liver sausages and patées. Palsgaard® Citrem 3302 Palsgaard® Citrem 3307 Palsgaard® Citrem 3327 Palsgaard® DMG 0093 Palsgaard® DMG 0090 Palsgaard® 0054 Palsgaard® 0038 Frankfurter sausages Wiener sausage Bologna Retorted liver pâté Fine liver sausage of fatty acids (E-471) based on vegetable fats but with a fatty acid profile like tallow. The recipe and process are shown in table 6 and figure 4. For measuring the quality improvements we have evaluated the emulsion stability and the storage stability: Table 6: Recipe suggestion for liver sausages. Ingredient 25.00 Pork liver 22.40 Pork skin 5.00 Pork fat 34.00 Water 10.00 Nitrite curing salt 1.50 Ascorbic acid 0.10 Starch 1.00 Palsgaard Seasoning Sum Meat, fat, pork skin Boil to 70oC Hot water, curing salt, Palsgaard® 0090 Cut for approx. 6 minutes Chopped liver, ascorbic acid At temperature < 60oC and cut for approx. 4 minutes Cool sausages and store at temperature = 5oC Fill batter into casings Boil to core temperature of 75oC Mass % Posr II (10 - 12 %) ® Figure 4: The manufacturing process of liver sausages used in this trial. 0090 0.50 0.50 100 % Palsgaard Technical Paper - September 2010 How to improve the quality and reduce the costs of meat products by using emulsifiers 5 Figure 5: Stability test of liver sausages with and without addition of Palsgaard® DMG 0090. In different dosages. Storage stability (7 days) % loss ml / 20g emulsion Emulsion stability - centrifugation test water loss without emulsifier 0.3 % Palsgaard® DMG 0090 fat loss 0.5 % Palsgaard® DMG 0090 gel without emulsifier 0.3 % Palsgaard® DMG 0090 fat 0.5 % Palsgaard® DMG 0090 As it can be observed from the above results of our trials in figure 5 it is clear, that the addition of the emulsifier Palsgaard® DMG 0090 has a big impact on these quality parameters, and an increased dosage will improve the results. The emulsifiers impact on the cost of the final liver sausage has also Ingredient Sausage 1 Sausage 2 25.00 22.50 Pork (10-12 % fat) 28.00 24.60 Pork fat 28.10 32.00 5.00 5.00 10.00 12.00 Palsgaard® DMG 0090 0.00 0.50 Nitrite curing salt 1.65 1.65 Starch 1.00 1.00 Dextrose 0.70 0.20 Ascorbic acid 0.05 0.05 Patée seasoning 0.50 0.50 100 % 100 % Water Sum been examined. Please refer to table 7. Based on our trials we find a reduction of the costs of up to 6 % when comparing the liver sausages with and without the emulsifier Palsgaard® DMG 0090. No off flavours or smell Possible to optimize the cost-profile of the meat based product Conclusion In this paper we have discussed the use of emulsifiers like Citric acid esters of mono- and diglycerides of fatty acids (E-472c), monodiglycerides of fatty acids (E-471) and distilled monodiglyceride of fatty acids (E-471) and combinations of these. As described and shown above it is possible to improve both the quality of the meat based product and at the same time to reduce the costs of the product by adding emulsifiers to the products. We have presented the results obtained with Palsgaard® Citrem 3307 and Palsgaard® DMG 0090, but as explained there are more possibilities from Palsgaard A/S. Pork liver Pork skin • • Table 7: Recipes of two different liver sausages with and without Palsgaard® DMG 0090. We can summary our findings as below: • Emulsifiers give a smoother texture to the spreadable patées and the sausages • Use of Palsgaard® DMG 0090 creates a more stable emulsion with minimum fat and water separation during storage Therefore it is, as always, important to test and examine the results of Palsgaard´s emulsifiers in your own products and with your process equipment. However, it is also important to examine the legislation as it might differ from country to country. Palsgaard In addition to the above mentionned emulsifiers for meat products, Palsgaard also manufactures a wide range of emulsifiers and stabilizer blends for fine foods, lipid, bakery, confectionery, dairy and ice cream. For further information on the abilities of Palsgaard’s emulsifiers for meat products or if you would like to order samples, please contact Business Unit Manager Cai Christensen at ccc@ palsgaard.dk or +45 7682 7682. Palsgaard Technical Paper - September 2010 How to improve the quality and reduce the costs of meat products by using emulsifiers 6

© Copyright 2026