Sample-Separation Technologies: Improving Speed and Resolution

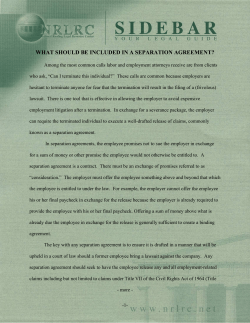

Life Science Technologies Separation Technologies Produced by the Science/AAAS Custom Publishing Office Sample-Separation Technologies: Improving Speed and Resolution Many scientific tasks—including studying the composition of blood and sequencing DNA—depend on being able to separate the parts from the whole. Only then can a scientist begin to understand how the pieces build up a process. To separate a sample into its components, scientists have been continually improving traditional approaches as well as developing new ones. In some cases, the improvements speed up separations; in others, advanced techniques provide new forms of separation that improve the efficiency of the processes. Though technologies are growing increasingly sophisticated, they are also becoming easier to use. By Mike May Gas Chromatography Autosampler “The marketplace is driving toward more speed and [better] resolution. That’s what seems to drive all of the techniques.” Upcoming Features Genomics: Exome Sequencing—October 11 Cell Culture: Scaling Up—December 6 196 areas of applied science, such as drug discovery and development in the pharmaceutical industry. TRENDS IN TECHNOLOGY Although separation technologies include a broad collection of tools, industry representatives can identify some overall trends occurring across the board in the development of these techniques. As an example, Ed Horton, senior marketing manager for analytical products at Beckman Coulter Life Sciences (Indianapolis, Indiana), says, “The marketplace is driving toward more speed and [better] resolution. That’s what seems to drive all of the techniques.” Another important trend that Horton mentions is that “separation technologies are starting to get more turnkey.” That is, the technologies are becoming more application specific. For example, he points out that specific techniques are now available to separate complex sugars, intact proteins, peptides, and ions. In LC, changes in the basic technology can speed up the process. According to Egidijus Machtejevas, global product manager for analytical chromatography at Merck KGaA (Darmstadt, Germany), “Monolithic technology is the future of chromatography.” In traditional chromatography, samples move through columns packed with particles, but monolithic technology uses columns filled with a porous silica-gel rod, such as Merck’s Chromolith High-Performance Liquid Chromatography (HPLC) columns. This monolithic approach can run four times faster than columns based on traditional particles. Also, Machtejevas points out that a scientist can easily upgrade to the monolithic approach by simply changing the column in an LC system. Beyond changing columns, different forms of chromatography can be used to separate the various components of a sample. Some methods are better suited for isolating compounds with specific properties. For instance, hydrophilic interaction liquid chromatography (HILIC) does a good job of pulling out small polar compounds. “We have two HILIC products—ZIC-pHILIC polymeric columns and SeQuant ZIC-cHILIC columns—that can separate very challenging compounds,” Machtejevas says. For example, the ZIC-cHILIC columns can be used to isolate melamine and cyanuric acid in infant formula. Charged components in a sample can also be separated with ion- www.sciencemag.org/products CREDIT: (FROM TOP) TANEWPIX/SHUTTERSTOCK.COM; © ISTOCKPHOTO.COM/ANGELBLUE1 I n many ways, some of the greatest advances in separation science arise from how the technologies are applied. In metabolomics, for instance, researchers try to isolate all of the substances formed via an organism’s metabolism. Studying the byproducts of these biochemical processes provides a challenge for scientists, and technology, since metabolites vary widely in their physical properties, such as size, charge, and concentration. To address these challenges, Vladimir Shulaev, professor of biological sciences at the University of North Texas in Denton, says, “We’re involved in developing new applications for metabolomics and new analysis methods.” For example, Shulaev and his colleagues explore ways to use advanced forms of liquid chromatography (LC) to screen metabolites. Shulaev and other scientists rely on a collection of separation technologies, including LC and gas chromatography (GC), plus approaches that use features of both. The development of new separation techniques helps researchers learn more about basic biological systems by breaking them into parts. Separation technologies are also important for many Inside a Gas Chromatography Analyzer Life Science Technologies Separation Technologies CREDIT: © ISTOCKPHOTO.COM/SELVANEGRA Produced by the Science/AAAS Custom Publishing Office provides “the ability to increase the efficiency and analytical power” of separations. “The major Some scientists run both HPLC and UHPLC. For example, a pharmaceutical company could already rely on separation validated assays for drug processing with HPLC that it challenge is that doesn’t want to change, but still want to explore new these biological assays with UHPLC. Agilent developed its 1290 Infinity Quaternary LC System to run both methods. To run an molecules are HPLC method on UHPLC, Agilent developed its Intelbecoming more ligent System Emulation Technology (ISET). The ISET complex.” transfers the method from one platform to another, including both older Agilent LC platforms and even systems from competitors. Other companies also develop versatile LC tools. For exchange chromatography (IC), which uses columns with charged sites example, Phenomenex (Torrance, California), offers its Kinetex to pull out ions. Linda Lopez, chromatography marketing manager Core-Shell Technology LC columns. “These columns can be used on the at Thermo Fisher Scientific (Sunnyvale, California), says that IC is a newest UHPLC systems as well as older HPLCs that run at lower presgood choice when “you need more information per unit time for closely sures,” says Michael McGinley, product manager at Phenomenex. Late eluting ions.” She adds, “This works well for separating carbohydrates in 2012, Phenomenex added to the Kinetex line with a 5 µm column and glycans. You can do selective separations of highly branched for small-scale preparative LC and a 1.3 µm column for use with UHcarbohydrates.” Researchers interested in metabolomics often study PLC systems. “We offer multiple particle sizes so that our columns are platform these molecules, especially glycans. Thermo Fisher Scientific’s ICS4000 and ICS-5000 are dedicated capillary IC systems. “These systems independent,” McGinley explains. “Older instruments can still run the are reagent free,” Lopez says. “You just add deionized water.” Since the 5 µm and 2.6 µm columns.” separations take place in capillary tubes, these systems don’t even use much water—only about 5.25 L per year for the ICS-4000, according NEXT GENERATION CHROMATOGRAPHY to product literature. Some people think that chromatography expands largely through increMany advances for separation technology focus on the stationary mental advances, but Richard Lee, chromatography marketing manager phase—the component in a column that captures the desired ele- at Bio-Rad (Hercules, CA), believes that his company’s next generaments in a sample—but the mobile phase, or solvent, matters just as tion chromatography (NGC) brings a big change. The NGC systems are much. The solvent that carries the sample through the column plays based on modular components with a plug-and-play format, and the an equally important role in the overall separation and including dif- modularity makes NGC very versatile. “A customer can buy whatever ferent additives in the solvent can also improve the separation. “The component they need—such as a pump to deliver buffers and samples, gold-standard additive for protein and amino-acid separations is tri- different detection systems, or buffer-blending—and add it to their fluoroacetic acid (TFA),” says Tony Nooner, senior chemist at Co- NGC system to expand its capabilities,” says Lee. vaChem (Loves Park, Illinois). If analyzing the separated analytes with “Not all people who use chromatography are experts,” Lee says. “So mass spectrometry (MS), however, TFA can reduce the ionization ef- they may not be familiar with how to properly plumb a system or proficiency of the sample, which effectively hides some of the peptides. gram a method.” With the NGC system’s ChromLab software, when a To maintain the quality of the separation and allow sensitive analysis user clicks a flow path, LED lights flash on the hardware to show where with MS, CovaChem offers a solvent-additive mixture that is 0.1 per- plumbing connections must be made. cent formic acid and 0.01 percent TFA. “This provides a good tradeoff Advanced separation also benefits other techniques. Sage Science between optimal peak separation and efficient analyte ionizations,” (Beverly, Massachusetts) develops separation technologies that prepare Nooner says. DNA for a variety of applications, including next generation sequencing. For many of these applications, says Chris Boles, chief scientific MOVING METHODS TO HPLC officer of Sage Science, “the size distribution has to be very tight.” That Originally, the force of gravity pushed the mobile phase in LC, making means collecting only DNA that is within a few percent of the targeted it so-called low pressure LC. By using a pump to push the mobile phase, length. The technology should also return as much of the targeted DNA scientists developed HPLC. (Sometimes, HPLC is even described as possible and have high reproducibility. In most cases, a standard DC power supply drives the electrophoresis as “high-pressure” LC, instead of “high-performance” LC.) Typically, HPLC operates at pressures up to 5,000 pounds per square inch (psi). that separates DNA moving through an agarose gel. “Last year,” says Ultra-HPLC (UHPLC) systems use pressures as high as 18,000 psi, or Boles, “we introduced an instrument, the BluePippin, that does pulsed-field electrophoresis. The traditional range of DC power lets even higher. Adding pressure to LC helps scientists separate compounds more you separate DNA samples as large as 10,000–15,000 bases, but our completely. As Jens Trafkowski, product manager, analytical HPLC pulse-field approach expands that range up to 50,000 bases.” He adds, at Agilent Technologies (Santa Clara, California), says, UHPLC “Pulsing the field slows down the electrophoretic continued> www.sciencemag.org/products 197 Life Science Technologies Separation Technologies Produced by the Science/AAAS Custom Publishing Office Featured Participants Agilent Technologies www.agilent.com PerkinElmer www.perkinelmer.com BAC BV/Life Technologies www.lifetechnologies.com Phenomenex www.phenomenex.com Beckman Coulter Life Sciences www.beckmancoulter.com Sage Science www.sagescience.com Biogen-Idec www.biogenidec.com Bio-Rad www.bio-rad.com CovaChem www.covachem.com Thermo Fisher Scientific www.thermofisher.com University of North Texas www.unt.edu Waters www.waters.com Merck KGaA www.emdgroup.com process for large DNA molecules and gives you tremendous resolution in terms of separating by molecular weight.” This technology can also separate proteins. BIG OPPORTUNITIES WITH BIOPHARMACEUTICALS Many of today’s drugs—including growth factors and interferons—are biological molecules. “The major separation challenge is that these biological molecules are becoming more complex,” says Laurens Sierkstra, chief executive officer at BAC BV, which was recently acquired by Life Technologies (Carlsbad, California). “Lots of biologicals have been pretty simple in the past, with simpler recombinant proteins and straightforward antibodies, but now there’s a totally new wave of molecules, including improved biologics with extended half-lives and antibody fragments.” He adds, “This makes everything more complicated from a separation point of view, and the process development is complicated and becoming even more [so].” BAC’s CaptureSelect technology—an antibody-based approach to separation—can be used in large-scale manufacturing for purifying biologics. Life Technologies offers a range of products that purify antibodies, viruses, and other biologics. Sierkstra indicates that Biogen-Idec, a U.S.-based biotechnology company, used CaptureSelect technology in developing a purification strategy for its recombinant Factor VIII-Fc fusion molecule, and has submitted a biologics license application to the U.S. Food and Drug Administration. This biologic treats hemophilia A—an inherited defect that reduces blood’s ability to clot—and is a long acting recombinant Factor VIII. “Biogen wanted a non-animal–derived purification process,” says Sierkstra, “and we made this very simple by supplying to them an off-the-shelf purification product.” Work in such biological drugs and biosimilars—biological pharmaceuticals that closely resemble innovative biotherapeutics—could drive increasing needs in separation technology. Both the original biologics and the biosimilars must be characterized during development. For such characterization, Horton says that many companies use Beckman 198 Coulter’s PA 800 plus Pharmaceutical Analysis System. This platform performs separations with sodium dodecyl sulfate (SDS)-based capillary electrophoresis. “This can be used to analyze samples for charge heterogeneity, molecular-weight heterogeneity, and other features,” Horton says. This platform can also be used in other application areas, such as metabolomics. Urine, which often includes highly charged components, often serves as a sample for these studies. Because of that charge, says Horton, “you miss a large subset of the metabolites unless you use capillary electrophoresis.” COMBINING TECHNOLOGIES Separation often gets combined with detection. In fact, Hayley Crowe, global mass spectrometry commercialization leader at PerkinElmer (Waltham, Massachusetts), says, “In LC/MS or GC/MS, the instruments are being used in more labs as detectors.” She adds, “With that concept comes people who might not have much training in MS. So we have to come up with easier-to-use instruments that still give the quality MS results.” To address this need, PerkinElmer developed the AxION iQT GC/ MS/MS. This instrument includes a proprietary approach to MS that, Crowe says, provides a broad dynamic range that is similar to the triple-quadrupole MS, but has the accuracy and speed of a quadrupole time-of-flight MS instrument. To enable easy-to-run experiments, especially for inexperienced users, software handles much of the operation, including automatically optimizing the settings when working with known compounds. It is especially useful, Crowe says, “where someone needs to detect something that is at trace levels in a really dirty sample.” To get even more information about the components in a sample, a scientist can use a different technology for separations. For example, the ACQUITY UPC2 System from Waters (Milford, Massachusetts) provides convergence chromatography. Program Manager Mark Baynham explains that this system “uses compressed CO2 gas and liquids as cosolvents.” With this combination of solvents, this technology can pull out components that might be overlapping in LC or GC separations. If a sample’s components are not clearly separated, the detector might miss them. “For instance if you’re looking for pharmaceutical impurities,” says Baynham, “you want to make sure that nothing is hiding, and [the ACQUITY UPC2] can help find things that other techniques miss.” He adds, “Neither the separation nor the detection is king; it is the optimization of both that leads to the best analytical answers, and we are working to make sure [our technology] is compatible with the full suite of mass spectrometers.” Separating the many different components of a sample can require a range of tools, but in the end, the separation technique that a scientist chooses must also be optimized for the subsequent detection method, such as MS. Sample separations are often not meant to stand alone, but instead perform a crucial, early step in the scientific processes that underlie many new discoveries, ranging from deciphering an organism’s metabolome to finding key molecules for fighting cancer. Mike May is a publishing consultant for science and technology. DOI: 10.1126/science.opms.p1300078 www.sciencemag.org/products

© Copyright 2026