By Ravi Mullapudi, PhD University of Houston

By Ravi Mullapudi, PhD University of Houston Houston, Texas, USA 1 OUTLINE I. INTRODUCTION II. THEORITICAL MODEL III. EXPERIMENTAL PROGRAM IV. ANALYTICAL STUDY V. TEST RESULTS VI. SUMMARY AND CONCLUDING REMARKS 2 I. INTRODUCTION : General Behavior of RC Columns Investigate the complex behavior of bridge columns under combined loading and its impact on the response of bridge system through experimental and analytical studies Kobe Earthquake Shear Failure Shinkansen bridge Japan Kobe Earthquake Hanshin Express Way Failure by Combined Loadings (Axial + Shear + Bending + Torsion) Northridge Earthquake in California Bending Failure 3 I. INTRODUCTION : NEES Project Overview Investigation of Combined Actions on Bridge Earthquake Response UNR Dynamic Shake Table Tests UH Finite Element Models & Development of Models Missouri S&T Slow cyclic tests & Development of Models UIUC Pseudodynamic tests UCLA Soil Structure Interaction WU Educational, Outreach, and Training Modules Final Deliverables: 1. Further Improved Understanding of Bridge Columns under Combined Loadings 2. Develop Finite Element Simulating Models 3. Interaction Diagram of Moment, Shear and Torsion 4. Development of Design Guidelines 5. Educational Modules 4 I. INTRODUCTION Investigate the structural response of individual column under following loading conditions and develop FE Models • • • Axial + Shear +Bending Axial + Torsion Axial + Shear + Bending + Torsion Analytical Study Experimental Study Develop Useful Design Tools Upgrade Design Details for Columns Investigate the impact of column behavior on whole bridge system Estimate possible critical loading conditions due to • • Geometrical conditions External load (Earthquake etc..) 5 I. INTRODUCTION : Research Significance No analytical models to include the effect of torsion and combined loadings No simplified design guidelines and interaction diagrams No information on quantification of degree of damage and correlation with engineering limit states under combined loading To identify the changes in existing performance levels in the presence of torsional loadings 6 52" (4.33') 175.75" (14.65') 16" 7" Main frame left column Adding 10 more out of plane hydraulic 20 Yokes cylinders 55" 175.75" 55" Main frame bottom beam 40 in plane hydraulic cylinders 8“ bore size, @ 5000 psi, Four out plane beams 200 kip tension Apply 250of kip compression, Supporting beams Main frame right column Out of plane frame 7 II. THEORETICAL MODEL : Universal Panel Tester Main frame top beam II. THEORETICAL MODEL : Fiber Element Micro Models Macro Models – Based on 2D – Based on Frame-Type Membrane/3D Brick Elements Elements – Suitable for System – Suitable for Component Evaluation (e.g. Evaluation (e.g. Joints) Buildings/Bridges) 8 II. THEORETICAL MODEL : Fiber Element Adopt a Timoshenko Beam Formulation with Shear Deformations Impose Equilibrium in Transverse Direction to Determine Concrete Lateral Strain Rotate Stresses to Principal (Crack) Directions Use Concrete Biaxial Constitutive Models (Softened Membrane Model) 9 II. THEORETICAL MODEL : Macro-Modeling of RC Elements y Y j z j Z Y Z X 10 II. THEORETICAL MODEL : Softening (ς) P Stress/Strain Curve in Principal 1-2 Coordinate of Applied Stress Non Softened Curve cracks Softened Curve y lt xy 1 12 2 1 2 ς x 2 1c c 12 12 1 Concrete Element in Concrete Element in Principal Cartesian Coordinate System 1-2 Coordinate of Applied Stress System 2c c 12 2c 1c 12c G 12 11 II. THEORETICAL MODEL : Material - Concrete Hsu (1993) fc Non Softened f c' ε20 ε0 f εc ε0 ' c A Softened 0.2ςfc' O 0.8ςfc' o o 2εo fc B c ε20 C c A ( ε0 , fC ) ' Mullapudi and Ayoub (2010) D (1 , f 1 ) m m Stress, fc G EC O EC EC 1F H B(ε20 ,0.2 fC ) ' E 0.5Er C 0.2 fC ' (1t ,0) 1 Er (-εr ,-fr ) R r E20 fr 20 Strain, εc 12 II. THEORETICAL MODEL : Material - Steel 1 2 C 2 (ε0 ,σ0 ) 1 (εr ,σ r ) E1 B R = R0- With Isotropic Strain Hardening Approach (Filippou 1983) a1 ε y (εm - ε0 ) a2 ε y + εm - ε0 Stress σ E0 εy σ = bε + * * ε* = 2 2 (ε r , σ r ) A 1 1 (ε0 ,σ0 ) Strain * (1 - b)ε* (1+ ε*R )1/R ε - εr ε0 - εr σ = σ - σr σ0 - σ r ε Bare steel bar Steel bar in concrete Stress fy fn With Smeared Steel Approach (Belarbi and Hsu 1994, 1995) n y Strain Bauschinger Effect fy 13 II. THEORETICAL MODEL : Softening Models The in-plane element considered in this model (x-y) Coordinate system.......Longitudinal &Transverse steel direction (1-2) Coordinate system……Applied principle stresses direction…reinforced concrete (r-d) Coordinate system……Concrete principle stresses direction… unreinforced concrete αr1β τxy 12c τxy 1 σx x σ2 σ1 12c r 1 σ1 stresses of RC element Rotating Angle αr …Concrete principle stresses Deviation Angle ….source of Contribution of the concrete shear Stress RA-STM………α r SMM/FA-STM………….. 1 r σy σ2 Fixed Angle1 …. Applied principle d y 2 14 II. THEORETICAL MODEL : Mohr Circle - Angles Rotating Matrix 2 cos R( ) = sin2 -cos sin sin cos 2 cos sin 2 2cos sin -2cos sin cos 2 - sin 2 2 ( xc , xy ) 21 2 r d ( 2c , 12c ) 2αr1 r 2 12c r σy αr1 τxy c 12 γ 2 σ 2c d ( 2 , 0.5 12 ) τxy σ c 12 ( x , 0.5 xy ) σ 1c 21 2 r 2αr1 (1c , 12c ) 2αr1 y d r 1 1 σx c 1 σ 2c (1 , 0.5 12 ) r 2αr1 12 2α*r ( y , 0.5 xy ) ( yc , xy ) 1 2 1c 2c tan 2αr 2 xy c x c y tan 2α1 2 xy x y xy tan 2αr x y 15 x II. THEORETICAL MODEL : Constitutive Model Compression/Tension region (Hsu and Zhu 2002) 2 p f c f1 1 f 2 f c f3 1 5.8 f1 1 f 2 f c 0.9 f 1 3 1 4001 fc 24 Biaxial Tension region Biaxial Compression region (Kupfer et al.) ip i fc i 1 0.92 ip 0.76 ip f c f c 2 Tensile strength is constant 16 II. THEORETICAL MODEL : Fiber Element – 2D Modeling Local Stiffness Uniaxial Strains x 1 2 R(α1 ) y 0.5 0.5 12 xy Dlo c Equivalent Uniaxial Strains 1 1 2 2 0.5 0.5 12 12 12 1 12 21 1 1 12 21 0 0 0 1 E1c 12 1 12 21 E2c 1 12 21 0 0 0 c G12 c 12 1c 2c 0.5 12 1 2 c G12 Hsu/Zhu Ratios (Modified Poisson Ratios) 1 1 12 21 21 1 12 21 0 E1c 1 12 21 E2c 21 1 12 21 0 D c 12 c lo 12 Global Stiffness Dgl R(1 ) Dlo R(1 ) c x x Dgl * y y xy xy c 17 II. THEORETICAL MODEL : Fiber Element – Equilibrium At each fiber equilibrium equations that relate the applied stresses to the internal stress of reinforcements and of concrete are as follows: σ x cos 2 α1 2 σ y = sin α1 τ cosα sinα 1 1 xy sin 2 α1 cos 2 θ -cosα1 sinα1 -2cosα1 sinα1 σ 1c f stx 2cosα1 sinα1 σ 2c + ρsty f sty c cos 2 α1 - sin 2 α1 τ12 0 Transverse strain can be evaluated with help of equilibrium equations 18 II. THEORETICAL MODEL : Force Based Formulation N Force-based frame models assume “exact” force Interpolation functions P Element result is exact for the beam theory Very few structural DOF’s Accurate in representation of curvature localization at plastic zone L x 1 Force Interpolation N ( x) 0 function 0 Section Force = 0 0 1 1 L L x x 1 L L N N V N ( x) M 1 M M 2 Moment Mu Curvature κ 0 ( x) N Strains ( x) f ( x) V ( x) M f ( x) = Flexibility Matrix 19 III. EXPERIMENT : MS&T Column Axial Force using Prestressing (approximately 7 % of predicted axial capacity) Belarbi et al.(2007) Strong Wall Load Cell Hydralic Jack Load Stub Two Hydraulic Actuators Steel Strands (Inside Column) 12 ft Test Unit Support Blocks Strong Floor f c' = 4.85 ksi Longitudinal yield stress = 66.4 ksi Transverse yield stress = 65.2 ksi 2 ft 20 III. EXPERIMENT : Test Matrix and Column Details Reinforcement Detail Reinforcement Ratios 12 #8 (25 mm) Longitudinal bars l For Flexure Design Purpose #3 (9.5 mm) or #4 (12.7 mm) Spiral at 2.75 in. (70 mm) C/C t 100 Al 2.10% Ag 100 dc Asp sAc 0.73% or = 1.32% 1 in. (25 mm) Clear Cover COLUMNS PROPERTY H/D(6) T/M(0) H/D(6) T/M(∞) H/D(3) T/M(∞ ) H/D(6) T/M(0.4) H/D(6) T/M(0.2) H/D(6) T/M(0.4) 37.9 27.2 25.7 41.2 Average Compressive Strength26.5 was 40 MPa H/D(6) T/M(0.2) Compressive Strength (f’c,MPa) 33.4 Modulus of Rupture (fcr, MPa) 3.52 3.86 3.25 3.52 3.38 3.93 3.86 Spiral Reinforcement Ratio (%) 0.73 0.73 1.32 0.73 0.73 1.32 1.32 Longitudinal Reinforcement Ratio (%) 2.10 Spiral Yield Strength (fty, MPa) 450 Longitudinal Yield Strength (fly, MPa) 457 41.2 21 1V. ANALYTICAL STUDY : Cyclic Curve 12 ft Column MS&T Column Axial Load = 113 kip 60 Experiment Load (k) 30 Fiber Element Analysis 0 -30 -60 -10 0 10 20 Displacement (in) Strength and energy dissipation are well represented by the developed element. 22 V. TEST RESULTS Progression of Damage under Flexure Buckling of Longitudinal Rebars Ductility-1 At yielding of the longitudinal reinforcement in the first layer Ductility-3 At ultimate Ductility-12 The test column could not resist any further load due to the buckling of the longitudinal reinforcement 23 1V. ANALYTICAL STUDY : Load Displacement MS&T Column 6 ft Column Axial Load = 113 kip Shear Force (kip) 200 160 120 Experiment Force Model - 1 Element Displ. Model - 1 Element Displ. Model - 5 Element Displ. Model - 15 Element 80 40 0 0 2 4 6 Displacement (in) 8 10 Force-based model was able to capture the behavior with only one element. 15 elements of the displacement-based model are required to reach convergence. 24 1V. ANALYTICAL STUDY : Earthquake Analysis Axial Load = 355 kN UNR Column- 9S1 Laplace et al. (2001) Cover Region 0.4 Core Region Acceleration (g) Transverse Reinforcement 0.92% Longitudinal Reinforcement 3.5% 406.4 mm (16 in.) Dia. 1.0 x EL Centro 0.3 0.2 0.1 0 -0.1 -0.2 16” -0.3 -0.4 0 10 20 30 40 50 60 Time (sec) 2.5 x EL Centro NS 25 1V. ANALYTICAL STUDY : Load Displacement UNR Column- 9S1 500 400 300 Experiment Shear Element Base shear (kN) 200 100 0 -100 -200 -300 -400 -500 -50 -45 -40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 Displacement (mm) 26 1V. ANALYTICAL STUDY : Longitudinal Reinforcement UNR Column- 9S1 1400 . Shear Element - 2.5 x El Centro Experiment - 2.5 x El Centro Shear Element - 1.0 x El Centro Experiment - 1.0 x El Centro Column Height (mm) 1200 1000 800 Loading 600 Gauge 1 400 200 0 -0.002 -0.001 0 0.001 0.002 Bar Strain (mm/mm) 0.003 0.004 Shear element predicted fairly accurate comparing to experimental values 27 1V. ANALYTICAL STUDY : Spiral Reinforcement 1400 . UNR Column- 9S1 1200 Column Height (mm) 1000 800 Shear Element - 2.5 El Centro Experiment - 2.5 El Centro Shear Element - 1.0 El Centro Experiment - 1.0 El Centro 600 400 Loading Gauge 2 200 0 0 0.001 0.002 0.003 Bar Strain (mm/mm) 0.004 The shear model accurately predicted the transverse strains along the plastic hinge length, but slightly overestimated the values near the column ends. This is in part due to the presence of the loading blocks which were not accounted for in the finite element model. 28 II. THEORETICAL MODEL : 3D Modeling To Develop a Beam Element for Analysis of combined loadings including the torsion. y yy yz zy zz z yx zx xy xz xx x 29 II. THEORETICAL MODEL : 3D – Beam Element Y u1 1 x z2 z1 v1 v2 X u2 L, EI x2 w2 w1 1y y2 Y V1 1 x T N1 M 1z M z2 V2 X N2 L, EI Tx2 W2 W1 M 1y M y2 Timoshenko Beam formulation Displacement and Force Formulations STM/SMM Constitutive Laws 30 II. THEORETICAL MODEL : 3D – Constitutive Model Vecchio & Selby Approach xx xx yy zz yy zz xy D 2 xy yz yz 2 xz xz 2 f1 1 f 2 fc f3 1 0.9 1 4001 f c' ( MPa) 5.8 1 24 No Complete 3D- Model available Assuming the same relation ship for intermediate stress calculation Implemented the 3D procedure to SMM 3 f ( 3 , 1 ) 1 f (1 , 3 ) 2 f ( 2 , 1 ) 31 1V. ANALYTICAL STUDY : Wall Peng and Wong (2010) Longitudinal Steel: 8, 12 mm dia. Transverse Steel: 10 mm dia, 200 C/C f c' = 40.2 Mpa Longitudinal yield stress = 535 MPa Transverse yield stress = 564 MPai Eccentricities 0mm 100 mm 400 mm 32 1V. ANALYTICAL STUDY : Wall Peng and Wong (2010) 400 mm Eccentricity SW10-400 wall 350 Flexural Shear (kN) 300 250 SW10-0 Analysis SW10-400 Experiment SW10-400 Analysis 200 150 100 50 0 0 5 10 15 20 25 30 Lateral Displacement (mm) Failed in shear mode Flexural strength was reduced to 60% and the flexural ductility reduced to 90% comparing to the SW10-0 wall response. 33 1V. ANALYTICAL STUDY : Wall Peng and Wong (2010) SW10-400 wall 400 mm Eccentricity 70 Torque (kNm) 60 50 40 SW10-400 Experiment SW10-400 Analysis 30 20 10 0 0 1 2 3 Twist Angle (deg./m) 4 5 At first yield, transverse reinforcement was yielded first but at peak load both the longitudinal and transverse steel has been yielded. 34 III. EXPERIMENT : MS&T Column Axial Force using Prestressing (approximately 7 % of predicted axial capacity) Belarbi et al. Strong Wall Load Cell Hydralic Jack Load Stub Two Hydraulic Actuators Steel Strands (Inside Column) 12 ft Test Unit Support Blocks Strong Floor f c' = 4.85 ksi Longitudinal yield stress = 66.4 ksi Transverse yield stress = 65.2 ksi 2 ft Spiral reinforcement ratio 0.73% Longitudinal reinforcement ratio 2.1% 35 1V. ANALYTICAL STUDY : Load Displacement MS&T Column (Combined Bending/Torsion) Column H/D(6)-T/M(0.2) 60 50 Load (kip) 40 Experiment T/M 0.2 Analysis T/M 0 Analysis T/M 0.2 30 20 10 0 0 2 4 6 8 10 Displacement (in) Load - Displacement response matched well with the experiment Increase of the torque reduced the load resisting capacity 36 1V. ANALYTICAL STUDY : Load - Steel Strain MS&T Column (Combined Bending/Torsion) Column H/D(6)-T/M(0.2) 50 40 Experiment T/M 0.2 Analysis T/M 0.2 Load (kip) 30 20 Gauge 1 17 in 10 0 0 500 1000 1500 2000 2500 3000 3500 4000 Micro Strain Longitudinal steel response matched well with the experiment Model captured the yielding and strains values 37 1V. ANALYTICAL STUDY : Load Displacement MS&T Column (Combined Bending/Shear/Torsion) Column H/D(3)-T/M(0.2) Spiral reinforcement ratio 1.32% Longitudinal reinforcement ratio 2.1% 120 Shear Force (kip) 100 80 Analysis Experiment 60 40 20 0 0 1 2 3 4 5 Displacement (in) Column failed in flexure shear mode Column showed stable flexural capacity because of the higher spiral ratio 38 1V. ANALYTICAL STUDY : Torque -Twist MS&T Column (Combined Bending/Torsion) Column H/D(3)-T/M(0.2) Spiral reinforcement ratio 1.32% Longitudinal reinforcement ratio 2.1% 1600 Analysis Experiment 1400 Torque (k-in) 1200 1000 800 600 400 200 0 0 1 2 3 4 Twist (deg.) Peak torsional moment was reached at a twisting angle of 0.85 deg. At peak longitudinal steel at bottom of the column was yielded first and after spiral reinforcement was yielded at bottom of the column. 39 V. TEST RESULTS H/D(6)-T/M(0) 0.84 m 0.67 m 0.54 m 2.43 m 3.70 m Effect of Torsional Moment (Long Column) H/D(6)-T/M(0.1) H/D(6)-T/M(0.2) Torsional Moment Increase H/D(6)-T/M(0.4) H/D(6)-T/M(∞) 40 V. TEST RESULTS H/D(3)-T/M(0) 1.83 m 0.73 m 0.45 m 1.3 m Effect of Torsional Moment (Short Column) H/D(3)-T/M(0.2) H/D(3)-T/M(0.4) Torsional Moment Increase H/D(3)-T/M(∞) 41 III. EXPERIMENT : Earthquake Analysis UNR Column- C1 Arias-Acosta and Sanders (2010) f ' = 32 MPa c X Y 0.6x Petrolia at Mendocino (1992) 42 Earthquake 1V. ANALYTICAL STUDY : Load - Displacement UNR Column- C1 X C om ponent Y C om ponent 60 150 E x p e r im e n t E x p e r im e n t 100 40 A n a ly s is B a se S h e a r (k N ) B a se S h e a r (k N ) A n a ly s is 50 0 -5 0 -1 0 0 20 0 -2 0 -4 0 -1 5 0 -6 0 -4 0 -2 0 0 20 D ix p la c e m e n t ( m m ) 40 60 -3 0 -2 0 -1 0 0 10 20 30 D ix p la c e m e n t ( m m ) Shear element predicted fairly accurate comparing to experimental values 43 V. TEST RESULTS: Effect of Spiral Ratio on T-M Interaction T-M Interaction at Peak Torque 450 400 Spiral Ratio-0.73% 350 Spiral Ratio-1.32% Analytical Predictions T (kN-m) 300 250 Prediction from Analytical Model 200 150 100 50 First longitudinal bar yielding Flexural cracking 0 0 100 200 300 400 500 600 700 800 900 1000 M (kN-m) Increase in torsional and flexural strength under combined bending and torsion and pure torsion is clearly evident in the interaction diagram with increase in spiral ratio 44 VI. SUMMARY AND CONCLUDING REMARKS The numerical method of analysis developed in the study, which is based on SMM, is able to predict the response of beams, walls, columns subjected to static, reverse cyclic, and dynamic loading. The stiffness, cracking, yield point, ultimate strength, energy dissipation and failure modes have been predicted satisfactorily in most cases. Displacement and force based fiber beam element for analysis of combined loadings including torsion was developed. For bending-shear load, columns with aspect ratio more than three and walls with aspect ratio more than two are failed under flexure-shear mode with the formation of plastic hinge at the base of the column or wall followed by core degradation. Failure of columns under combined loadings including torsion, the location of the plastic hinge zone shift upwards from the base of the column or wall based on the increase of T/M ratio. 45 VI. SUMMARY AND CONCLUDING REMARKS Increase of bending and torsional moments reduces the torsional moment required to cause yielding of the transverse reinforcement and yielding of the longitudinal reinforcement. An increase of spiral reinforcement ratio increases the confinement to the concrete core, decreases the spiral yielding occurrence, increases the peak torsional strength and improves the torsional strength and twist ductility with a better redistribution of the shear stresses. With a reduction in aspect ratio, reduces the displacement and twist at ultimate resisting load and prone to fail predominantly in shear. Fiber element accounts for the torsional sensitive structures with 1D frame elements. Model is accurately predicting the combined loadings including torsion. 46 ACKNOWLEDGEMENTS Network for Earthquake Engineering Simulation National Science Foundation 47

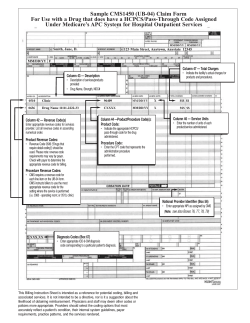

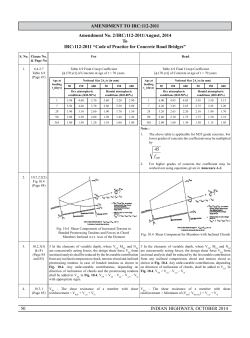

© Copyright 2026