Arria 10 Hard Processor System Technical Reference Manual 101 Innovation Drive

Arria 10 Hard Processor System Technical

Reference Manual

Subscribe

Send Feedback

a10_5v4

2014.08.18

101 Innovation Drive

San Jose, CA 95134

www.altera.com

TOC-2

Arria 10 Hard Processor System Technical Reference Manual

Contents

Introduction to Arria 10 Hard Processor System..............................................1-1

Features of the HPS......................................................................................................................................1-3

HPS Block Diagram and System Integration...........................................................................................1-4

HPS Block Diagram.........................................................................................................................1-4

MPU Subsystem...............................................................................................................................1-5

Coresight Debug and Trace............................................................................................................1-5

System Interconnect........................................................................................................................1-5

Memory Controllers........................................................................................................................1-6

Support Peripherals.........................................................................................................................1-8

Interface Peripherals......................................................................................................................1-10

On-Chip Memory..........................................................................................................................1-12

Endian Support..........................................................................................................................................1-12

HPS-FPGA Interfaces................................................................................................................................1-13

HPS Address Map......................................................................................................................................1-14

HPS Address Spaces......................................................................................................................1-14

Address Map and Register Definitions.......................................................................................1-16

Document Revision History.....................................................................................................................1-16

Clock Manager.....................................................................................................2-1

Features of the Clock Manager..................................................................................................................2-1

Clock Manager Block Diagram and System Integration........................................................................2-3

Functional Description of the Clock Manager........................................................................................2-4

Clock Manager Building Blocks.....................................................................................................2-4

PLL Integration................................................................................................................................2-6

Hardware-Managed and Software-Managed Clocks..................................................................2-8

Hardware Sequenced Clock Groups.............................................................................................2-8

Software Sequenced Clocks..........................................................................................................2-10

Resets...............................................................................................................................................2-12

Security............................................................................................................................................2-13

Interrupts........................................................................................................................................2-14

Address Map and Register Definitions...................................................................................................2-15

Document Revision History.....................................................................................................................2-15

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-3

Reset Manager.....................................................................................................3-1

Reset Manager Block Diagram and System Integration.........................................................................3-3

Reset Controller................................................................................................................................3-4

Security Reset Functions.................................................................................................................3-7

Module Reset Signals.......................................................................................................................3-7

Slave Interface and Status Register..............................................................................................3-12

Functional Description of the Reset Manager.......................................................................................3-13

Reset Sequencing............................................................................................................................3-14

Reset Pins........................................................................................................................................3-18

Reset Effects....................................................................................................................................3-18

Reset Handshaking........................................................................................................................3-19

Address Map and Register Definitions...................................................................................................3-19

Document Revision History.....................................................................................................................3-19

FPGA Manager....................................................................................................4-1

Features of the FPGA Manager..................................................................................................................4-1

FPGA Manager Block Diagram and System Integration.......................................................................4-2

Functional Description of the FPGA Manager........................................................................................4-3

FPGA Configuration.......................................................................................................................4-3

FPGA Status......................................................................................................................................4-4

Error Message Extraction................................................................................................................4-4

Data AES Decryption......................................................................................................................4-4

JTAG Hosting...................................................................................................................................4-4

Boot Handshake...............................................................................................................................4-5

General Purpose I/O........................................................................................................................4-5

Clock..................................................................................................................................................4-5

Reset...................................................................................................................................................4-5

Address Map and Register Definitions.....................................................................................................4-5

Document Revision History.......................................................................................................................4-6

System Manager...................................................................................................5-1

Features of the System Manager................................................................................................................5-1

System Manager Block Diagram and System Integration......................................................................5-2

Functional Description of the System Manager......................................................................................5-3

Boot Configuration and System Information..............................................................................5-3

Additional Module Control............................................................................................................5-3

Altera Corporation

TOC-4

Arria 10 Hard Processor System Technical Reference Manual

FPGA Interface Enables..................................................................................................................5-6

ECC and Parity Control..................................................................................................................5-7

Preloader Handoff Information.....................................................................................................5-7

Clocks.................................................................................................................................................5-7

Resets.................................................................................................................................................5-8

Address Map and Register Definitions.....................................................................................................5-8

Document Revision History.......................................................................................................................5-8

SoC Security.........................................................................................................6-1

Security Manager.........................................................................................................................................6-2

Security Manager Block Diagram..................................................................................................6-2

Functional Overview.......................................................................................................................6-2

Functional Description....................................................................................................................6-3

Security System Extensions........................................................................................................................6-7

TrustZone..........................................................................................................................................6-7

Secure Firewall................................................................................................................................6-10

Address Map and Register Definitions...................................................................................................6-20

Revision History.........................................................................................................................................6-20

System Interconnect............................................................................................7-1

About the System Interconnect..................................................................................................................7-2

Features of the System Interconnect.............................................................................................7-2

System Interconnect Block Diagram and System Integration...................................................7-2

Secure Firewall..................................................................................................................................7-6

About the Rate Adapter..................................................................................................................7-6

About the Scheduler........................................................................................................................7-7

About the HMC Adapter................................................................................................................7-7

About Arbitration............................................................................................................................7-8

About the Observability Network..................................................................................................7-9

Functional Description of the System Interconnect.............................................................................7-10

SDRAM Address Space.................................................................................................................7-11

L3 Address Space...........................................................................................................................7-11

Address Remapping.......................................................................................................................7-11

Secure Transaction Protection.....................................................................................................7-11

System Interconnect Master Properties......................................................................................7-12

System Interconnect Slave Properties.........................................................................................7-13

Clocks..............................................................................................................................................7-15

Resets...............................................................................................................................................7-15

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-5

Functional Description of the Rate Adapter..............................................................................7-15

Functional Description of the Firewall.......................................................................................7-16

Functional Description of the Scheduler....................................................................................7-17

Functional Description of the SDRAM L3 Interconnect.........................................................7-17

Functional Description of the Arbitration.................................................................................7-19

Functional Description of the Observability Network.............................................................7-20

Configuring the System Interconnect.....................................................................................................7-20

Configuring the Scheduler............................................................................................................7-20

Configuring the HMC Controller...............................................................................................7-21

Configuring the Observability Network.....................................................................................7-21

Address Map and Register Definitions...................................................................................................7-21

Document Revision History.....................................................................................................................7-21

HPS-FPGA Bridges.............................................................................................8-1

Features of the HPS-FPGA Bridges...........................................................................................................8-1

HPS-FPGA Bridges Block Diagram and System Integration................................................................8-3

Functional Description of the HPS-FPGA Bridges.................................................................................8-3

Functional Description of the FPGA-to-HPS Bridge.................................................................8-3

Functional Description of the HPS-to-FPGA Bridge.................................................................8-7

Functional Description of the Lightweight HPS-to-FPGA Bridge.........................................8-10

Clocks and Resets...........................................................................................................................8-13

Data Width Sizing..........................................................................................................................8-14

Address Map and Register Definitions...................................................................................................8-15

Document Revision History.....................................................................................................................8-15

Cortex-A9 Microprocessor Unit Subsystem.......................................................9-1

Features of the Cortex-A9 MPU Subsystem............................................................................................9-1

Cortex-A9 MPU Subsystem Block Diagram and System Integration..................................................9-2

Cortex-A9 MPU Subsystem with System Interconnect.............................................................9-2

Cortex-A9 MPU Subsystem Internals...........................................................................................9-3

Cortex-A9 MPCore......................................................................................................................................9-4

Functional Description....................................................................................................................9-4

Implementation Details...................................................................................................................9-5

Cortex-A9 Processor........................................................................................................................9-5

Interactive Debugging Features.....................................................................................................9-6

L1 Caches..........................................................................................................................................9-7

Preload Engine.................................................................................................................................9-7

Floating Point Unit..........................................................................................................................9-7

Altera Corporation

TOC-6

Arria 10 Hard Processor System Technical Reference Manual

NEON Multimedia Processing Engine.........................................................................................9-8

Memory Management Unit............................................................................................................9-9

Performance Monitoring Unit.....................................................................................................9-11

MPCore Timers..............................................................................................................................9-11

Generic Interrupt Controller........................................................................................................9-11

Global Timer...................................................................................................................................9-25

Snoop Control Unit.......................................................................................................................9-25

Accelerator Coherency Port.........................................................................................................9-27

L2 Cache......................................................................................................................................................9-29

Functional Description.................................................................................................................9-29

ECC Support...................................................................................................................................9-30

Implementation Details................................................................................................................9-31

CPU Prefetch..............................................................................................................................................9-33

TrustZone....................................................................................................................................................9-33

Secure Partitioning........................................................................................................................9-34

Virtual Processor Operation........................................................................................................9-35

Debugging Modules...................................................................................................................................9-36

Program Trace................................................................................................................................9-36

Event Trace.....................................................................................................................................9-37

Cross-Triggering............................................................................................................................9-37

Clocks..........................................................................................................................................................9-37

Cortex-A9 MPU Subsystem Register Implementation........................................................................9-38

Cortex-A9 MPU Subsystem Address Map.................................................................................9-38

L2 Cache Controller Address Map..............................................................................................9-39

Document Revision History.....................................................................................................................9-40

CoreSight Debug and Trace..............................................................................10-1

Features of CoreSight Debug and Trace.................................................................................................10-1

ARM CoreSight Documentation.............................................................................................................10-2

CoreSight Debug and Trace Block Diagram and System Integration................................................10-3

Functional Description of CoreSight Debug and Trace.......................................................................10-4

Debug Access Port (DAP)............................................................................................................10-4

System Trace Macrocell (STM)....................................................................................................10-4

Trace Funnel...................................................................................................................................10-5

Embedded Trace FIFO (ETF)......................................................................................................10-5

AMBA Trace Bus Replicator (Replicator)..................................................................................10-5

Embedded Trace Router (ETR)...................................................................................................10-5

Trace Port Interface Unit (TPIU)................................................................................................10-6

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-7

Embedded Cross Trigger (ECT) System.....................................................................................10-6

Program Trace Macrocell (PTM)..............................................................................................10-10

HPS Debug APB Interface..........................................................................................................10-11

CoreSight Debug and Trace Programming Model.............................................................................10-11

ROM Table...................................................................................................................................10-11

STM Channels..............................................................................................................................10-12

FPGA Interface.............................................................................................................................10-13

CTI Trigger Connections to Outside the Debug System.......................................................10-14

Configuring Embedded Cross-Trigger Connections.............................................................10-16

Debug Clocks................................................................................................................................10-17

Debug Resets................................................................................................................................10-18

Address Map and Register Definitions.................................................................................................10-19

Document Revision History...................................................................................................................10-19

Error Checking and Correction Controller......................................................11-1

ECC Controller Features...........................................................................................................................11-1

ECC Supported Memories........................................................................................................................11-1

ECC Controller Block Diagram and System Integration.....................................................................11-2

ECC Controller Functional Description.................................................................................................11-2

Overview.........................................................................................................................................11-2

ECC Structure.................................................................................................................................11-3

Memory Data Initialization..........................................................................................................11-4

Indirect Memory Access...............................................................................................................11-5

Error Logging.................................................................................................................................11-5

Interrupts........................................................................................................................................11-6

Initialization and Configuration..................................................................................................11-8

Clocks..............................................................................................................................................11-9

Reset.................................................................................................................................................11-9

Address Map and Register Definitions.......................................................................................11-9

Revision History.........................................................................................................................................11-9

On-Chip Memory..............................................................................................12-1

On-Chip RAM............................................................................................................................................12-1

Features of the On-Chip RAM.....................................................................................................12-1

On-Chip RAM Block Diagram and System Integration..........................................................12-2

Functional Description of the On-Chip RAM...........................................................................12-2

Boot ROM...................................................................................................................................................12-3

Features of the Boot ROM............................................................................................................12-3

Altera Corporation

TOC-8

Arria 10 Hard Processor System Technical Reference Manual

Boot ROM Block Diagram and System Integration..................................................................12-4

Functional Description of the Boot ROM..................................................................................12-4

Address Map and Register Definitions...................................................................................................12-5

Document Revision History.....................................................................................................................12-5

NAND Flash Controller....................................................................................13-1

NAND Flash Controller Features............................................................................................................13-1

NAND Flash Controller Block Diagram and System Integration......................................................13-1

Functional Description of the NAND Flash Controller.......................................................................13-2

Discovery and Initialization.........................................................................................................13-2

Bootstrap Interface........................................................................................................................13-3

Configuration by Host..................................................................................................................13-4

Local Memory Buffer.....................................................................................................................13-5

Clocks..............................................................................................................................................13-5

Resets...............................................................................................................................................13-5

Indexed Addressing.......................................................................................................................13-6

Command Mapping......................................................................................................................13-7

Data DMA.....................................................................................................................................13-12

ECC................................................................................................................................................13-16

Interface Signals...........................................................................................................................13-19

NAND Flash Controller Programming Model...................................................................................13-20

Basic Flash Programming...........................................................................................................13-20

Flash-Related Special Function Operations.............................................................................13-24

Address Map and Register Definitions.................................................................................................13-31

Document Revision History...................................................................................................................13-31

SD/MMC Controller..........................................................................................14-1

Features of the SD/MMC Controller......................................................................................................14-1

SD Card Support Matrix...............................................................................................................14-2

MMC Support Matrix...................................................................................................................14-3

SD/MMC Controller Block Diagram and System Integration............................................................14-3

Functional Description of the SD/MMC Controller............................................................................14-4

SD/MMC/CE-ATA Protocol........................................................................................................14-4

BIU...................................................................................................................................................14-5

CIU.................................................................................................................................................14-20

Clocks............................................................................................................................................14-33

Resets.............................................................................................................................................14-34

Interface Signals...........................................................................................................................14-34

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-9

SD/MMC Controller Programming Model.........................................................................................14-35

Software and Hardware Restrictions†.......................................................................................14-35

Initialization†................................................................................................................................14-36

Controller/DMA/FIFO Buffer Reset Usage.............................................................................14-42

Non-Data Transfer Commands.................................................................................................14-42

Data Transfer Commands..........................................................................................................14-44

Transfer Stop and Abort Commands........................................................................................14-51

Internal DMA Controller Operations.......................................................................................14-52

Commands for SDIO Card Devices..........................................................................................14-54

CE-ATA Data Transfer Commands.........................................................................................14-56

Card Read Threshold..................................................................................................................14-64

Interrupt and Error Handling....................................................................................................14-66

Booting Operation for eMMC and MMC................................................................................14-68

Voltage Switching....................................................................................................................................14-78

Address Map and Register Definitions.................................................................................................14-78

Document Revision History...................................................................................................................14-78

Quad SPI Flash Controller................................................................................15-1

Features of the Quad SPI Flash Controller.............................................................................................15-1

Quad SPI Flash Controller Block Diagram and System Integration..................................................15-2

Functional Description of the Quad SPI Flash Controller...................................................................15-3

Overview.........................................................................................................................................15-3

Data Slave Interface.......................................................................................................................15-3

SPI Legacy Mode............................................................................................................................15-7

Register Slave Interface.................................................................................................................15-7

Local Memory Buffer.....................................................................................................................15-8

DMA Peripheral Request Controller..........................................................................................15-8

Arbitration between Direct/Indirect Access Controller and STIG.........................................15-9

Configuring the Flash Device.......................................................................................................15-9

XIP Mode......................................................................................................................................15-11

Write Protection..........................................................................................................................15-11

Data Slave Sequential Access Detection...................................................................................15-12

Clocks............................................................................................................................................15-12

Resets.............................................................................................................................................15-12

Interrupts......................................................................................................................................15-13

Interface Pins................................................................................................................................15-14

Quad SPI Flash Controller Programming Model...............................................................................15-15

Setting Up the Quad SPI Flash Controller...............................................................................15-15

Altera Corporation

TOC-10

Arria 10 Hard Processor System Technical Reference Manual

Indirect Read Operation with DMA Disabled.........................................................................15-16

Indirect Read Operation with DMA Enabled..........................................................................15-16

Indirect Write Operation with DMA Disabled.......................................................................15-17

Indirect Write Operation with DMA Enabled........................................................................15-17

XIP Mode Operations.................................................................................................................15-18

Address Map and Register Definitions.................................................................................................15-19

Document Revision History...................................................................................................................15-19

DMA Controller................................................................................................16-1

Features of the DMA Controller..............................................................................................................16-1

DMA Controller Block Diagram and System Integration...................................................................16-3

Functional Description of the DMA Controller....................................................................................16-4

Operating States.............................................................................................................................16-4

Initializing the DMAC..................................................................................................................16-8

Using the Slave Interfaces.............................................................................................................16-9

Peripheral Request Interface......................................................................................................16-10

Using Events and Interrupts......................................................................................................16-15

Aborts............................................................................................................................................16-16

Security Usage..............................................................................................................................16-19

Programming Restrictions.........................................................................................................16-22

Constraints and Limitations of Use..........................................................................................16-26

DMA Controller Programming Model................................................................................................16-27

Instruction Syntax Conventions................................................................................................16-27

Instruction Set Summary............................................................................................................16-27

Instructions...................................................................................................................................16-28

Assembler Directives...................................................................................................................16-43

MFIFO Buffer Usage Overview.................................................................................................16-44

DMA Controller Registers......................................................................................................................16-51

Address Map and Register Definitions.....................................................................................16-53

Document Revision History...................................................................................................................16-53

Ethernet Media Access Controller....................................................................17-1

Features of the Ethernet MAC.................................................................................................................17-1

MAC................................................................................................................................................17-1

PHY Interface.................................................................................................................................17-2

DMA Interface...............................................................................................................................17-2

Management Interface..................................................................................................................17-2

Application Interface.....................................................................................................................17-3

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-11

Acceleration....................................................................................................................................17-3

EMAC Block Diagram and System Integration....................................................................................17-3

EMAC to RGMII Interface...........................................................................................................17-4

EMAC to FPGA GMII and MII PHY Interface.........................................................................17-5

EMAC to FPGA Application Interface.......................................................................................17-7

PHY Management Interface.......................................................................................................17-11

Functional Description of the EMAC...................................................................................................17-12

Host Interfaces.............................................................................................................................17-12

Transmit and Receive Data FIFO Buffers................................................................................17-14

Error Checking and Correction.................................................................................................17-14

IEEE 1588-2002 Timestamps.....................................................................................................17-15

IEEE 1588-2008 Advanced Timestamps..................................................................................17-21

IEEE 802.3az Energy Efficient Ethernet...................................................................................17-22

Checksum Offload.......................................................................................................................17-23

Frame Filtering.............................................................................................................................17-23

Clocks and Resets.........................................................................................................................17-25

Interrupts......................................................................................................................................17-26

Application Interface to FPGA Fabric......................................................................................17-26

Ethernet MAC Programming Model....................................................................................................17-26

DMA Controller...........................................................................................................................17-26

Descriptor Overview...................................................................................................................17-39

Initializing DMA..........................................................................................................................17-55

Initializing MAC..........................................................................................................................17-56

Performing Normal Receive and Transmit Operation...........................................................17-57

Stopping and Starting Transmission.........................................................................................17-57

Programming Guidelines for Energy Efficient Ethernet........................................................17-58

Programming Guidelines for Flexible Pulse-Per-Second (PPS) Output.............................17-59

Address Map and Register Definitions.................................................................................................17-61

Document Revision History...................................................................................................................17-61

USB 2.0 OTG Controller...................................................................................18-1

Features of the USB OTG Controller......................................................................................................18-2

Supported PHYS............................................................................................................................18-3

USB OTG Controller Block Diagram and System Integration...........................................................18-3

Functional Description of the USB OTG Controller............................................................................18-5

USB OTG Controller Block Description....................................................................................18-5

ULPI PHY Interface......................................................................................................................18-8

Local Memory Buffer.....................................................................................................................18-9

Altera Corporation

TOC-12

Arria 10 Hard Processor System Technical Reference Manual

Clocks..............................................................................................................................................18-9

Resets...............................................................................................................................................18-9

Interrupts......................................................................................................................................18-10

USB OTG Controller Programming Model.........................................................................................18-11

Enabling SPRAM ECCs..............................................................................................................18-12

Host Operation.............................................................................................................................18-12

Device Operation.........................................................................................................................18-13

Address Map and Register Definitions.................................................................................................18-15

Document Revision History...................................................................................................................18-15

SPI Controller....................................................................................................19-1

Features of the SPI Controller..................................................................................................................19-1

SPI Block Diagram and System Integration...........................................................................................19-2

SPI Block Diagram.........................................................................................................................19-2

Functional Description of the SPI Controller........................................................................................19-2

Protocol Details and Standards Compliance.............................................................................19-2

SPI Controller Overview...............................................................................................................19-3

Interface Pins..................................................................................................................................19-6

FPGA Routing................................................................................................................................19-7

Transfer Modes..............................................................................................................................19-8

SPI Master.......................................................................................................................................19-9

SPI Slave........................................................................................................................................19-12

Partner Connection Interfaces...................................................................................................19-14

DMA Controller Interface..........................................................................................................19-19

Slave Interface...............................................................................................................................19-19

Clocks and Resets.........................................................................................................................19-19

SPI Programming Model........................................................................................................................19-20

Master SPI and SSP Serial Transfers.........................................................................................19-21

Master Microwire Serial Transfers............................................................................................19-23

Slave SPI and SSP Serial Transfers............................................................................................19-25

Slave Microwire Serial Transfers...............................................................................................19-26

Software Control for Slave Selection.........................................................................................19-26

DMA Controller Operation.......................................................................................................19-27

Address Map and Register Definitions.................................................................................................19-30

Document Revision History...................................................................................................................19-30

I2C Controller....................................................................................................20-1

Features of the I2C Controller..................................................................................................................20-1

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-13

I2C Controller Block Diagram and System Integration.......................................................................20-2

Functional Description of the I2C Controller........................................................................................20-3

Feature Usage.................................................................................................................................20-3

Behavior...........................................................................................................................................20-3

Protocol Details..............................................................................................................................20-4

Multiple Master Arbitration.........................................................................................................20-8

Clock Frequency Configuration................................................................................................20-10

SDA Hold Time............................................................................................................................20-11

DMA Controller Interface..........................................................................................................20-12

Clocks............................................................................................................................................20-12

Resets.............................................................................................................................................20-12

Interface Pins................................................................................................................................20-12

2

I C Controller Programming Model.....................................................................................................20-14

Slave Mode Operation.................................................................................................................20-14

Master Mode Operation.............................................................................................................20-18

Disabling the I2C Controller......................................................................................................20-19

Abort Transfer..............................................................................................................................20-20

DMA Controller Operation.......................................................................................................20-20

Address Map and Register Definitions.................................................................................................20-23

Document Revision History...................................................................................................................20-23

UART Controller...............................................................................................21-1

UART Controller Features.......................................................................................................................21-1

UART Controller Block Diagram and System Integration..................................................................21-2

Functional Description of the UART Controller..................................................................................21-3

FIFO Buffer Support......................................................................................................................21-3

UART(RS232) Serial Protocol......................................................................................................21-3

Automatic Flow Control...............................................................................................................21-4

Interface Pins..................................................................................................................................21-6

FPGA Routing................................................................................................................................21-6

Clocks..............................................................................................................................................21-6

Resets...............................................................................................................................................21-7

Interrupts........................................................................................................................................21-7

DMA Controller Operation......................................................................................................................21-9

Transmit FIFO Underflow...........................................................................................................21-9

Transmit Watermark Level........................................................................................................21-10

Transmit FIFO Overflow............................................................................................................21-11

Receive FIFO Overflow...............................................................................................................21-11

Altera Corporation

TOC-14

Arria 10 Hard Processor System Technical Reference Manual

Receive Watermark Level...........................................................................................................21-12

Receive FIFO Underflow............................................................................................................21-12

Address Map and Register Definitions.................................................................................................21-12

Document Revision History...................................................................................................................21-13

General-Purpose I/O Interface.........................................................................22-1

Features of the GPIO Interface................................................................................................................22-1

GPIO Interface Block Diagram and System Integration......................................................................22-2

Functional Description of the GPIO Interface......................................................................................22-2

Debounce Operation.....................................................................................................................22-2

Pin Directions.................................................................................................................................22-3

GPIO Interface Programming Model.....................................................................................................22-3

Address Map and Register Definitions...................................................................................................22-3

Document Revision History.....................................................................................................................22-3

Timer .................................................................................................................23-1

Features of the Timer................................................................................................................................23-1

Timer Block Diagram and System Integration......................................................................................23-1

Functional Description of the Timer......................................................................................................23-2

Clocks..............................................................................................................................................23-2

Resets...............................................................................................................................................23-3

Interrupts........................................................................................................................................23-3

Timer Programming Model.....................................................................................................................23-3

Initialization....................................................................................................................................23-3

Enabling the Timer........................................................................................................................23-4

Disabling the Timer.......................................................................................................................23-4

Loading the Timer Countdown Value........................................................................................23-4

Servicing Interrupts.......................................................................................................................23-4

Address Map and Register Definitions...................................................................................................23-5

Document Revision History.....................................................................................................................23-5

Watchdog Timer................................................................................................24-1

Features of the Watchdog Timer.............................................................................................................24-1

Watchdog Timer Block Diagram and System Integration...................................................................24-2

Functional Description of the Watchdog Timer...................................................................................24-2

Watchdog Timer Counter............................................................................................................24-2

Watchdog Timer Pause Mode......................................................................................................24-3

Altera Corporation

Arria 10 Hard Processor System Technical Reference Manual

TOC-15

Watchdog Timer Clocks...............................................................................................................24-3

Watchdog Timer Resets................................................................................................................24-3

Watchdog Timer Programming Model..................................................................................................24-4

Setting the Timeout Period Values..............................................................................................24-4

Selecting the Output Response Mode.........................................................................................24-4

Enabling and Initially Starting a Watchdog Timer...................................................................24-4

Reloading a Watchdog Counter...................................................................................................24-4

Pausing a Watchdog Timer..........................................................................................................24-4

Disabling and Stopping a Watchdog Timer...............................................................................24-4

Watchdog Timer State Machine..................................................................................................24-5

Address Map and Register Definitions...................................................................................................24-6

Document Revision History.....................................................................................................................24-6

Hard Processor System I/O Pin Multiplexing..................................................25-1

Features of the HPS I/O Block.................................................................................................................25-1

HPS I/O Block Diagram and System Integration..................................................................................25-1

Functional Description of the HPS I/O..................................................................................................25-2

Control Registers............................................................................................................................25-2

Dedicated I/O Pins.........................................................................................................................25-3

Shared I/O Pins..............................................................................................................................25-5

Test Considerations...................................................................................................................................25-9

Address Map and Register Definitions.................................................................................................25-10

Document Revision History...................................................................................................................25-10

Booting and Configuration Introduction..........................................................A-1

Booting Overview........................................................................................................................................A-1

FPGA Configuration Overview.................................................................................................................A-1

Booting and Configuration Options........................................................................................................A-2

Boot Stages...................................................................................................................................................A-3

Boot Definitions..........................................................................................................................................A-4

Reset..................................................................................................................................................A-4

BootROM.........................................................................................................................................A-4

Boot Select........................................................................................................................................A-5

Clock Select......................................................................................................................................A-5

I/O Configuration...........................................................................................................................A-5

L4 Watchdog....................................................................................................................................A-6

Second Stage Boot Loader..............................................................................................................A-6

Boot Loader......................................................................................................................................A-6

Altera Corporation

TOC-16

Arria 10 Hard Processor System Technical Reference Manual

Secure Boot......................................................................................................................................A-6

Document Revision History......................................................................................................................A-7

Altera Corporation

Introduction to Arria 10 Hard Processor System

1

2014.08.18

a10_54001

Subscribe

Send Feedback

The SoC is divided into two distinct parts - a HPS portion and an FPGA portion.

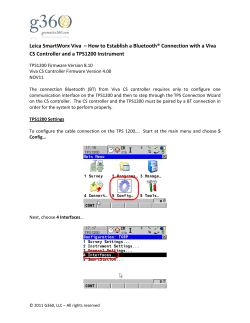

Figure 1-1 shows a high-level block diagram of the Altera SoC device. The following list explains the meaning

of some of the markings within this figure.

• Blocks connected to device pins have symbols (square with X) adjacent to them in the figure

• Dedicated I/O - I/O that is dedicated to an external non-volatile storage device (for Boot Flash), HPS

clock and resets

• Shared I/O - I/O that is dedicated to peripherals within the HPS or optionally FPGA logic

• FPGA I/O - I/O that is dedicated to the FPGA fabric. Some peripherals in the HPS can route signals to

the FPGA fabric that may connect to the FPGA I/O instead of the shared I/O of the HPS portion of the

device

© 2014 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words

and logos are trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other

words and logos identified as trademarks or service marks are the property of their respective holders as described at

www.altera.com/common/legal.html. Altera warrants performance of its semiconductor products to current specifications in accordance with

Altera's standard warranty, but reserves the right to make changes to any products and services at any time without notice. Altera assumes

no responsibility or liability arising out of the application or use of any information, product, or service described herein except as expressly

agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device specifications before relying on any published

information and before placing orders for products or services.

www.altera.com

101 Innovation Drive, San Jose, CA 95134

ISO

9001:2008

Registered

1-2

a10_54001

2014.08.18

Introduction to Arria 10 Hard Processor System

Figure 1-1: Altera SoC Device Block Diagram

Altera SoC Device

HPS Portion

FPGA Portion

Shared I/O

Dedicated I/O

Interface

Peripherals

Flash

Controllers

PLLs

CSS

User

I/O

HSSI

Transceivers

Cortex-A9

MPU

Subsystem

SDRAM L3

Interconnect

HPS-FPGA

Interfaces

FPGA Fabric

(LUTs, RAMs, Multipliers & Routing)

On-Chip

Memories

Support

Peripherals

Debug

Hard Memory

Controllers

Hard

PCIe

PLLs

Debug

The HPS contains a microprocessor unit (MPU) subsystem with dual ARM® Cortex®-A9 MPCore processors,

flash memory controllers, SDRAM L3 Interconnect, on-chip memories, support peripherals, interface

peripherals, debug capabilities, and phase-locked loop (PLLs). The dual-processor HPS supports symmetric

(SMP) and asymmetric (AMP) multiprocessing.

The FPGA portion of the device contains the FPGA fabric, a configuration sub-system (CSS), phase-locked

loops (PLLs), and depending on the device variant, high-speed serial interface (HSSI) transceivers, hard PCI

Express® (PCIe®) controllers, and hard memory controllers.

The HPS and FPGA portions of the device are distinctly different. The HPS can boot from multiple sources,

including the FPGA fabric and external flash. In contrast, the FPGA must be configured through either the

HPS or an externally supported device.

The HPS and FPGA portions of the device each have their own pins. The HPS has dedicated I/O pins and

can also share FPGA I/O pins. Software executing on the HPS assigns the I/O pins to the available HPS

modules and configures the I/O pins via I/O control registers. For more information, refer to the Hard

Processor System I/O Pin Multiplexing chapter. The FPGA I/O pins are configured by an FPGA configuration

image through the HPS or any external source supported by the device.

The MPU subsystem can boot from flash devices connected to the HPS pins. When the FPGA portion is

configured by an external source, the MPU subsystem can boot from flash memory devices available to the

FPGA portion of the device.

The HPS and FPGA portions of the device supports two power supply options:

• Both the FPGA portion and the HPS are powered ON.

• The FPGA portion is powered ON and the HPS is powered OFF.

Altera Corporation

Introduction to Arria 10 Hard Processor System

Send Feedback

a10_54001

2014.08.18

Features of the HPS

1-3

Related Information

• Hard Processor System I/O Pin Multiplexing on page 25-1

For more information, refer to the Hard Processor System I/O Pin Multiplexing chapter in the Hard

Processor System Technical Reference Manual.

• Booting and Configuration Introduction on page 26-1

Features of the HPS

The following list contains the main modules of the HPS:

• MPU subsystem featuring dual ARM Cortex-A9 MPCore processors

• System interconnect that includes six memory mapped interfaces between the HPS and FPGA

• Three FPGA ports

• Two 32-, 64-, or 128-bit ports

• One 32- or 64-bit port

• HPS-to-FPGA bridge

• Lightweight HPS-to-FPGA bridge

• FPGA-to-HPS bridge

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

General-purpose Direct Memory Access (DMA) controller

Three Ethernet media access controllers (EMACs)

Two USB 2.0 On-The-Go (OTG) controllers

NAND flash controller

Quad serial peripheral interface (SPI) flash controller

Secure Digital (SD) / MultiMediaCard (MMC) controller

Two SPI master controllers

Two SPI slave controllers

Five inter-integrated circuit (I2C) controllers

256 KB on-chip RAM

128 KB on-chip boot ROM

Two UARTs

Four system timers