CAMX 2014 keynote transcends aerospace and automotive Conferences abound: Around the

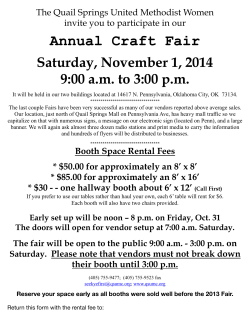

TUESDAY, OCTOBER 14, 2014 IN ASSOCIATION WITH Orlando,Florida Florida| |Orange OrangeCounty County Convention Center Orlando, Convention Center Conferences abound: ACMA and SAMPE have organized a robust conference program to meet a variety of composite needs. PG 3 Around the Convention Center: Restaurants, shopping and entertainment are within easy walking distance of CAMX. PG 5 www.theCAMX.org/mobile www.theCAMX.org/mobile CAMX 2014 keynote transcends aerospace and automotive By Jeff Sloan CompositesWorld Magazine compositesworld.com Planning your CAMX experience: CAMX offers a variety of tools to help you plan and maximize your conference and trade show experience. PG 3 CAMX 2014 officially starts on Tuesday, Oct. 14, at 9:30 a.m. in the Valencia Ballroom with the General Session and keynote address. The keynote for the inaugural CAMX will be presented by Kevin Mickey, president of renowned aerocomposites pioneer Scaled Composites (Mojave, Calif.). Mickey will share his ideas and perspectives from one of the most innovative companies in the composites industry. He is expected to highlight his experiences managing and leading to instill an entrepreneurial drive and culture at Scaled Composites, which developed and manufactured for Virgin Galactic SpaceShipOne and SpaceShipTwo, the latter of which will soon begin ferrying passengers into space on low-Earth orbit (LEO) excursions. SpaceShipTwo will be ferried for part of its journey by WhiteKnightTwo/Virgin MotherShip Eve; both craft feature significant use of carbon fiber composites. Mickey will also discuss the future of the Information on getting to and from CAMX via shuttle. PG 4 Kevin Mickey, president of Scaled Composites, presents a keynote address on Tuesday, Oct. 14, at 9:30 a.m. Products and services in the Exhibit Hall: SAMPE presents six Fellows Awards at CAMX 2014 Shuttle schedule: With more than 550 exhibitors, there is an abundance of new products and technologies to be found on the CAMX show floor. PG 9 EVENTS NOT TO MISS • Registration open: 7:00 a.m. – 5:00 p.m. • Conference programs: 8:00 – 9:00 a.m., 2:00 – 5:00 p.m. • General Session, Keynote, CAMX Awards: 9:30 – 10:45 a.m., Convention Center, Valencia Ballroom – 4th level • Exhibit Hall open: 11:00 a.m. – 5:00 p.m. • CAMX Featured Sessions: 2:00 – 5:00 p.m., Room W315 A/B • Welcome Reception: 5:00 – 6:00 p.m., Convention Center, Valencia Ballroom – 4th level See Keynote, continued on page 8 By Jeff Sloan CompositesWorld Magazine compositesworld.com SAMPE’s prestigious Fellows Award was presented Monday night to six new recipients. The Fellows Award represents prestigious recognition of a SAMPE member for distinguished contributions in the fields of materials and processes. The awards ceremony was held at the Hyatt Regency, Florida Ballroom B, 6 to 8 p.m. This year’s recipients are: • Gary G. Bond, associate technical fellow, The Boeing Co. (St. Louis, Mo.) • Dr. Ronald F. Gibson, distinguished research professor, Mechanical Engineering Department, University of Nevada, Reno (Reno, Nev.) • Dr. Johnny L. Golden, technical fellow (ret.), Boeing Research and Technology (Houston, Texas) • Dr. Howard A. Katzman, senior scientist, Space Materials Laboratory, The Aerospace Corp. (El Segundo, Calif.) • Dr. Andrew Long, executive dean, Faculty of Engineering, University of Nottingham (Nottingham, U.K.) • Dr. Yiping Qiu, dean of College of Textiles, Donghua University (Shanghai, China) Information about each of the award winners follows. Bond is an expert in fiber-reinforced polymer composite materials, processes and Gary G. Bond Dr. Ronald F. Gibson Dr. Howard A. Katzman Dr. Andrew Long Dr. Johnny L. Golden Dr. Yiping Qiu manufacturing procedures to make out-of-autoclave (OOA) vacuum bag only an enhanced affordability procedure for primary aerostructure platforms. As a teacher, lecturer and mentor to young professionals, he has fostered the development of the next generation of materials and process professionals. Gibson has a distinguished record as a mentor and educator to peers and students, and as an internationally recognized researcher and scholar in composite materials. His contributions in dynamic and time-dependent behavior, vibration test methods, rapid screening tests, and micromechanical modeling of composite materials are See Fellow Awards, continued on page 5 The most important thing we build is trust Excellence in Advanced Composite Production and Design Solutions Cobham is recognised as an industry leader for the design, development and manufacture of a wide range of composite structures. Cobham’s composite business units cover all composite processes including Resin Transfer Molding (RTM), Compression Molding, Hand Lay-up / Autoclave Cure, Advanced Bladder Molding and Filament Winding. Cobham’s award-winning composite products include aircraft engine components, aircraft and spacecraft structures, missile and munitions assemblies, pressure vessels, flywheel rims and radomes. Advanced Composite Solutions Ladder Brackets Composite Fan Blades Acoustic Panels Infill Panels Exhaust Flaps Spinner and Cap Terminal/Speed Probe Blocks Cobham Composite Products fabricates complex, hightolerance composite parts and assemblies including hightemperature engine components used on both military and commercial aircraft. Our 72,000 sq-ft facility located in San Diego, CA houses state-of-the-art compression molding presses that are automated and we utilize mechanized layup processes that are robust and repeatable to guarantee part to part consistency. Strategic Company Focus • High Temperature Aircraft Engine Components • Aircraft Engine Components and Structures Stator Vanes Ice Impact Panels Composite Fan Blades Advanced Design Solutions With core capabilities in energy storage and control, filament winding and metal to composites bonding, Cobham Life Support, in Westminster, MD produces innovative composite structures including the world’s first demisable spacecraft propellant tank, pressure vessels and flywheel rims all while meeting the most demanding weight, strength and safety requirements. Strategic Company Focus • • • • • Energy Storage Ultra-High Pressure Cylinders Aircraft Emergency Inflation and Oxygen Systems Spacecraft Components Military Rotorcraft Structures For sales inquiries or more information, please contact: Cobham Composite Products - San Diego, CA, USA T: 001 (858) 824 8958 Cobham Life Support - Westminster, MD, USA T: 001 (410) 871 9966, ext106 Visit Cobham at CAMX 2014 - Booth# 4453 www.cobham.com How to organize your exhibit hall experience By Jeff Sloan CompositesWorld Magazine compositesworld.com CAMX 2014 is the largest composites industry trade show and conference ever held in North America, so it’s important that you take advantage of the tools that will help you plan and organize your visit. With more than 550 exhibitors at CAMX 2014, you’ll want to maximize your time on the show floor so that you come away with the technology and product information you need to help optimize your composites fabrication operations. Show organizers ACMA and SAMPE are providing planning tools to help you get this done. First, call up on your smartphone or tablet device the CAMX website, www.thecamx.org/mobile, which has been optimized for mobile devices and offers the most complete and immediate access to the exhibitor list, show events and the conference program. Whether you’re on your computer or phone, first familiarize yourself with the Exhibit Hall, in the West Building of the Orange County Convention Center. MyCAMX lets you conduct exhibitor The mobile CAMX website provides an searches, add exhibitors and sessions to overview of the CAMX floor plan (find it your Planner, make notes about each under the Attendees tab on the desktop exhibitor, share your list of favorite exhibisite), which is laid out in 31 aisles and tors with others, create events or appointincludes all exhibitor booths, plus the ments, and print your agenda or save it as Awards for Composites Excellence (ACE) a PDF. and CAMX Awards display areas. Furthermore, many CAMX exhibitors Next, familiarize yourself with the are sharing information about what they CAMX exhibitors using the site’s Exhibitor will feature in their exhibits. New prodDirectory (also under the Attendees tab ucts, featured technologies and major on the desktop site), which allows you to announcements from a variety of exhibsearch exhibitors by name or by product itors can be found on the Exhibitor Press category. Once you have a grasp of the Releases page on the desktop site. exhibitors and their technologies, you can start gathering product information and flagging the exhibitors that interest you the most. The MyCAMX Planner tool CAMX Mobile Website www.theCAMX.org/mobile (accessed from the Exhibitor Directory page on the desktop site) provides a great resource to www.facebook.com/theCAMX organize all of this information. Create an account on the CAMX website for the MyCAMX tool to www.twitter.com/the_CAMX (#CAMX14) help you aggregate the companies you want to visit in the Exhibit Hall www.tinyurl.com/theCAMXLinkedIn and sessions you want to attend throughout the conference. Stay Connected! Conference half of CAMX offers many, varied options By Sara Black CompositesWorld Magazine compositesworld.com CAMX is offering a powerful program of presentations, tutorials, keynotes, featured sessions and a poster session, combining the best of SAMPE and ACMA education strategies. Conference tracks include Business; IN ASSOCIATION WITH Orlando, Florida County Center Orlando, Florida| Orange | Orange CountyConvention Con- www.theCAMX.org/mobile www.theCAMX.org/mobile SHOWDAILY STAFF CONTRIBUTORS CompositesWorld Magazine Jeff Sloan, Editor-In-Chief Mike Musselman, Managing Editor Sara Black, Technical Editor Ginger Gardiner, Senior Editor Rick Kline Jr., Group Publisher Ryan Delahanty, Publisher Kim Hoodin, Marketing Director Barb Businger, District Manager Rick Brandt, District Manager Eddie Kania, European Sales Manager SHOWDAILY PRODUCTION Rhonda Weaver, Production Manager Stephanie Monsanty, Editor Jeff Norgord, Art Director/Photographer Becky Helton, Advertising Manager The CAMX ShowDaily is published by Gardner Business Media, Inc. 6915 Valley Ave., Cincinnati, OH 45245 © 2014 by Gardner Business Media, Inc. Design, Analysis and Testing; Green Composites; Manufacturing; Market Applications; New Materials/ Nanotechnology; Process Advancements; Regulatory and Legislative; Traditional Materials; and Transportation. Featured session topics include the following: Advances in Reinforcement Materials (Glass Fiber Materials), Automation Advances (and Their Issues, Needs and Challenges); Challenges to Additive Manufacturing and DARPA’s Open Manufacturing Approach (includes 3D Printing); Composites in Clean Energy Applications (Department of Energy Programs); Consumer Product Market Opportunities; Designing Composites for Design and Manufacturing Efficiency; Designing for Composites Sustainability; Developments and Expansion in Alternative Energy Markets; Education Requirements to Support Market Growth; Infrastructure Markets: Needs, Possibilities, Advances; Natural Fiber Technology Advancements; Recycling — Cradle to Grave Responsibility; The Automotive Market — Where is it Going and What’s Needed?; and Thermoset Resin & Composites Advancements. In all, more than 53 technical topics will be addressed by hundreds of qualified speakers. To find your sessions of interest, consult the printed program you receive at registration. Or, you can find and save presentations and sessions of interest when you create an account through MyCAMX. Your selections will be saved to your personal schedule, which is accessible via a smartphone via the CAMX mobile website. The conference program begins today at 8 a.m. Morning sessions include a University Research Symposium and a NIST session that will discuss the Consortium for Accelerated Innovation and Insertion of Advanced Composites (CAIIAC). Don’t miss the General Session and Keynote address, which begins at 9:30 this morning. The keynote speaker is Kevin Mickey, the president of Scaled Composites, who will share his viewpoints as head of one of the most innovative companies in the composites industry. On Wednesday, Oct. 15, watch for the International Cast Polymer Assn.’s (ICPA) General Session and Awards Luncheon. And, on Thursday morning, starting at 7:30 a.m. and running until 11 a.m., a workshop will be held on the topic of “Advancing the State of Composites Manufacturing in the U.S. through Facilitating Industry by Engineering, Roadmapping and Science (FIBERS) Consortium. A small portion of the CAMX conference program contains presentations regulated by International Traffic in Arms Regulations (ITAR), and admittance is restricted to U.S. citizens. Look for ITAR information at the registration area. www.theCAMX.org/mobile 3 THE COMPOSITES AND ADVANCED MATERIALS EXPO CAMX shuttle bus schedule The Convention Center shuttle bus stops are located in the main bus drop-off area between the Exhibit Hall C Lobby area and Conference Program Rooms W224. If you require an ADA shuttle bus or would like additional information, call 310-466-4699. (Call at least 30 minutes prior to desired pickup time if an ADA bus is required.) Hotel Route BUS ROUTE HOTEL HOTEL SHUTTLE BOARDING LOCATION Avanti Resort 1 Curbside, International Dr. Courtyard Orlando International Drive 1 Curbside, Austrian Ct. Embassy Suites Orlando — International Drive South 1 I-Ride Trolley Stop 22, International Dr. Rosen Inn Pointe Orlando 1 Curbside, International Dr. Hampton Inn Orlando 2 Walk to Springhill Suites, curbside, Universal Blvd. Homewood Suites by Hilton Orlando 2 Walk to Springhill Suites, curbside, Universal Blvd. Hyatt Place Orlando/Convention Center 2 Walk to Springhill Suites, curbside, Universal Blvd. Residence Inn Orlando Convention Center 2 Walk to Springhill Suites, curbside, Universal Blvd. Springhill Suites Orlando Convention Center 2 Curbside, Universal Blvd. DoubleTree 3 Outside of main lobby Hours of Shuttle Bus Service* Tuesday, Oct. 14 7:00 a.m.-7:00 p.m. Every 10-15 minutes Wednesday, Oct. 15 7:00 a.m.-10:00 a.m. Every 10-15 minutes 10:00 a.m.-3:00 p.m. Every 30 minutes 3:00 p.m.-7:00 p.m. Every 10-15 minutes 7:00 a.m.-2:00 p.m. Every 10-15 minutes 2:00 p.m.-6:00 p.m. Every 30 minutes Thursday, Oct. 16 *Shuttle departs Convention Center on the hour and half hour. Schedule may vary due to traffic and weather conditions. Last bus leaves from hotel 30 minutes prior to end time with no return service. CAMX on-floor demonstrations By Jeff Sloan CompositesWorld Magazine compositesworld.com There is no shortage of actual manufacturing taking place at CAMX, some of it designed to highlight capability, some of it to educate composite professionals on manufacturing processing methods. Whatever your level of interest, there are several manufacturing demonstration options on the show floor. Below is a list of exhibitors that have reported they are offering demonstrations: • A&P Technology, Booth 2447: Fiber reinforcement and braided products • Composites One, Booth 2570: Closed molding processes • Entec Composite Machines, Booth 3561: High-speed filament winding 4 Tuesday, October 14, 2014 • MarkForged, Booth 1533: Continuous fiber additive manufacturing • NETZSCH Instruments, Booth 1643: Material analysis instruments • RocTool, Booth 4365: High-speed injection, heating, cooling • Sandvik Process Systems, Booth 3768: Continuous process systems • SWORL, Booth 3261: Reusable vacuum membranes Within walking distance: Much to do, see and eat By Jeff Sloan CompositesWorld Magazine compositesworld.com If you’ve come to CAMX without a car, worry not. There is much do, see and eat within walking distance of the Orange County Convention Center (OCCC) and its surrounding hotels. The place with the most dining and entertainment options is Pointe Orlando, an outdoor pedestrian mall located just north of the OCCC on International Drive, the main thoroughfare that runs in front of the convention center. At Point Orlando you’ll find restaurants like Adobe Gila’s, B.B. King’s Blues Club, Copper Canyon Grill, Cuba Libre Restaurant & Rum Bar, Johnny Rockets, Maggiano’s Little Italy, The Capital Grille, Tommy Bahama Restaurant and Bar, and more. If you want to be entertained, at Pointe Orlando you’ll find Regal Cinemas as well as Wonderworks, “an indoor amusement park for the mind, with more than 100 hands-on exhibits,” including a famous upside-down house. West as well as north of Pointe Orlando you’ll find Ming Court Oriental Cuisine, Houlihan’s, Sizzler, Taverna Opa, ICEBAR Orlando (home of the largest permanent ice bar in the world) and Miller’s Ale House (a neighborhood tavern and sports bar). Venture a little further north still and you’ll find RA Sushi Bar Restaurant, Dave & Buster’s, Howl at the Moon (a dueling piano bar), Olive Garden and Drip (an industrial bar — be prepared to get paint on your clothes). If you seek more pedestrian fare, east of the OCCC and within walking distance you’ll find Denny’s, Red Lobster, McDonald’s and IHOP. If walking is not your speed, you can take the I-Ride Trolley, which stops all along International Drive. A one-time ride from any point A to point B on International Drive is $2. Or you can pay $5 for an all-day pass. Finally, if walking and trolleying don’t appeal to you, check out Air Florida Helicopter Charters, located west of International Drive just north of Pointe Orlando. Fellow Awards, continued from page 1 particularly noteworthy. Golden has established broad expertise in the materials and processes (M&P) field through his leadership of the International Space Station M&P team for 20 years, from development of design and verification requirements through hardware manufacturing, test and assembly in orbit, to station operations and service life extension. Katzman has worked with advanced composite systems for more than 35 years, characterizing new materials and evaluating composite applications for National Security Space (NSS) programs. His research activities have included fundamental work in metals, carbon, polymers and ceramic matrix composites, as well as applied research into spacecraft aging issues and structural composite materials. His expertise and contributions as a materials and processing technical specialist have been recognized by the U.S. Air Force as well as other agencies within the Department of Defense. Long is internationally recognized as an expert in modeling of composite processes and performance. He has worked as chairman of the U.K. and Ireland SAMPE chapter, which has prospered under his leadership. In particular the student seminar has done well sending U.K. students on to win the Paris event, and from there to visit SAMPE’s spring conference in the U.S. Yiping is well known for his work in 3-D woven fabric composites and composite interface modification. He is a leader in the SAMPE Shanghai Chapter and the founder and faculty advisor of the SAMPE Donghua University Student Chapter. The Donghua student chapter is the first in China and the largest in the world. Innovation in Motion See a wide range of innovative solutions on display at our booth...and be sure to check out these 3M technical session presentations: Nanosilica-Modified Tooling Prepregs James Nelson Composite Erosion Protection Films Ryan Marx Nanosilica-Modified Epoxies for Filament-Wound Drive Shafts James Nelson V i si t Bo o t h u s at 26 durin 39 g CA M X ! For dates and times, see the latest presentation schedule posted at the 3M booth. Join the Winners’ Circle! Sign up at the 3M booth for your chance to win great 3M Racing NASCAR® -themed prizes! Enabling lighter, safer, quieter vehicles – constructed faster. NASCAR is a registered trademark of the National Association for Stock Car Auto Racing, Inc. www.theCAMX.org/mobile 5 THE COMPOSITES AND ADVANCED MATERIALS EXPO ACE, CAMX Awards recognize composites creativity, excellence By Jeff Sloan CompositesWorld Magazine compositesworld.com CAMX 2014 offers two awards programs, one representing a legacy ACMA event, with the other making its debut. The Awards for Composites Excellence (ACE) has been a staple of ACMA events for many years and returns this year to join the CAMX show. It offers awards in six categories, covering design, manufacturing and market growth. New to the show is the CAMX Awards, which recognizes two cutting-edge innovations or innovators that are shaping the future of composites and advanced materials. There are, in total, more than 80 entrants in the ACE and CAMX Awards, and all can be seen at the Awards Pavilion in the CAMX Exhibit Hall. Winners in each category will be announced this morning at the Opening Session, Keynote and CAMX Awards, 9:30-10:45 a.m. in the Valencia Ballroom, fourth level of the West Hall Convention Center. Awards will be presented Thursday at the ACMA & SAMPE Awards Luncheon, 12-2 p.m. The entrants represent the full range of markets and applications served by the composites industry. Below are some of the notable examples that might be worth closer examination. Blackbird Clara is a concert-sized composite ukulele with the previously unobtainable combination of world-class sound and vintage look in a wood-free, worry-free and sustainable package. The high-performance hollow-neck, uni-body construction is free of the durability and weather stability issues suffered by wooden instruments, making Clara the perfect take-everywhere instrument. Clara is made of Ekoa, a lighter-than-carbon, renewable flax/bioresin prepreg developed by Blackbird and Lingrove. This new bio-based solution is tuned to sound like a Stradivarius, but is unusually strong and thus offers an alternative to cutting down old-growth trees. Cargo Composites entered the AeroBox, a lightweight 58-kg/123-lb air cargo container used in the belly of wide-body aircraft to transport baggage, mail and cargo. The low weight of this unit saves approximately $1,250 per year in fuel 6 Tuesday, October 14, 2014 controlled, but also the ratio of reinforcement to resin (LOI) can be easily and consistently controlled. The near dripless applicator helps optimize resin impregnation, consistently providing a 70 to 80 percent glass-to-resin ratio. The TSE applicator can be cleaned in place and put back in service in just 7 to 10 minutes. Studio Twenty Seven Architecture has entered its information and ticket pavilion for Union Station’s (Washington, D.C.) new intercity bus terminal, which achieves required functionality with a colorful, modern design, transforming a concrete parking deck into an inviting passenger and 7,800 kg/17,196 lb of CO2 emissions compared to the 82-kg/181-kg aluminum container it replaces. The innovative thermoplastic composite honeycomb panels not only produce a lighter structure, but greatly improve durability. Repair rates of this material in this extremely rough handling environment are one-quarter those of aluminum, leading to a lower lifecycle cost. The 100 percent recyclable panels are thermoformed at the edges to create a structural corner when assembled. This feature eliminates the need for damage-prone aluminum extrusions and greatly reduces the overall parts count. With more than 18,000 of these containers now flying in worldwide commercial airline fleets, the estimated annual total fuel savings is more than 25 million liters/6.6 million gal and CO2 savings are 1,476 metric tons/3.25 million lb. TSE Industries Inc. entered a new method of reinforcement (glass/carbon fiber) impregnation during filament winding. This method of impregnation not only minimizes process waste, but also maximizes the effective impregnation of reinforcement strands using minimal quantities of resin. TSE’s patented technology ensures better laminate quality through consistent impregnation. Not only can the roving tension be automatically waiting and transit area. Fiberglass and foam core sandwich panels enabled low-cost tooling and an extremely short 32-day timeline, providing both architects and contractors a solution not possible with traditional materials. Customized building skins integrate structural, waterproofing and thermal functions, reducing total elements yet enabling unique textures and shapes to offer huge market potential. The very creative, low-cost approach to texturing of facades showcases composites’ endless capacity for solutions. MarkForged entered its Mark One 3-D printer, the first 3-D printer designed to print continuous carbon fiber, Kevlar and fiberglass. Using a patent-pending Composite Filament Fabrication (CFF) process, MarkForged’s blend of thermoplastics immediately hardens during printing. CFF offers the opportunity to dramatically shorten design cycles and enables high-resolution fiber placement. The system uses a proprietary thermoplastic matrix that also offers good interlayer adhesion and high impact resistance not found in thermosetting resins. Based on in-house three-point bending tests, Mark One carbon fiber CFF 3-D-printed beams have a higher strengthto-weight (specific modulus) than 6061 T6 aluminum. Further, the user can easily turn billet parts into sandwich panels with printed-in core material. This greatly increases strength-to-weight while adding the desired panel stiffness to external facing components. NASA Glenn Research submitted the NASA Composite Cryotank Technology Demonstrator. NASA collaborated with Boeing to design, fabricate and test an all-composite cryogenic fuel tank for launch vehicles, paving the way for lower-cost access to space. These designs achieved a 30 percent weight savings and a 25 percent cost savings, allowing insertion of higher mass payloads to low-Earth orbit (LEO) and beyond. A number of technology firsts included thin-ply fiber placement of a large test article (5.5m/18-ft diameter) using out-of-autoclave (OOA) processing, and successful cure of a hybrid (thick and thin plies) laminate. Ultimately, the largest automated fiber placement (AFP), OOA, composite tank was fabricated as a result of this effort. It was also the first successful demonstration of an all-composite bolted sump/forward cover joint. NASA analytical capabilities facilitated the rapid development of models for AFP processes, and accurate prediction of structural response in a series of tests using liquid hydrogen (LH2) to thermally cycle the composite tank through various pressure ranges. OOA processing permitted as much as a 20 percent reduction in the power requirements compared to autoclave processing. The NASA Space Launch System (SLS) is being built and the use of composite cryotanks in the upper stage provides additional payload capacity. At the current SLS configuration of 8.4m, this warrants as much as 1,400 kg/3,806 lb of added payload. VX Aerospace submitted the VX-1 KittyHawk, a new aircraft with looks and performance that VX says will remake the light aircraft landscape, manned or unmanned. The aircraft has more usable internal volume and payload capacity and improved aerodynamic efficiency. An advantage of the increase in internal volume is the ability to incorporate compressed natural gas (CNG) as a fuel source, which will reduce the operational fuel cost by a factor of three. Equally important is the structural efficiency. The basic airframe consists of just six components, and there are no highly stressed parts in the design. Composite Panel Systems LLC is making waves in the building and construction industry with its Epitome Quality Foundation Walls, a high-performance composite-based improvement in lieu of current concrete residential foundations. The sandwich panel construction of Epitome foundation walls provides the homeowner with a warmer, drier and healthier living space (R-16.5 insulation value), as well as improved flexibility to modify or finish the basement at their leisure. For the builder, Epitome foundation walls combine structure, integrated See Awards, continued on page 8 Advanced Material Solutions Composite and Wafer Machining IKONICS AMS employs a unique machining technology, minimizing substrate compromise and maximizing perforation variety, including non-circular perforations on complex-curved, irregular surfaces. IKONICS AMS is particularly beneficial in applications featuring challenging material, ie: Carbon Matrix Composites (CMC), Ceramic Composites, and other brittle substrates. See us at Booth #1830 IKONICS Advanced Material Solutions 4832 Grand Avenue, Duluth, MN 55807 USA direct: (218) 624-6443 | toll free: (800) 328-4261 ext.358 | web: www.ikonicsams.com | email: [email protected] An IKONICS Company ISO 9001 Certified ITAR Compliant NASDAQ Listed: IKNX www.theCAMX.org/mobile 7 THE COMPOSITES AND ADVANCED MATERIALS EXPO Awards, continued from page 7 stud cavities for mechanicals, top plate and damp proofing into a single step. Further, the builder can now install a typical foundation in less than two hours with his own crew. Previously, builders could wait up to two weeks for a separate contractor to install a concrete basement. Moreover, Epitome foundation walls can withstand three times the backfill load of a standard Keynote, continued from page 1 composites and advanced materials industry, possibilities for transitioning aerospace-quality materials into an automotive-style production process and price point, and how the industry can approach traditional material users on the conversion to composites. He will also describe Scaled Composites’ approach to composite design and manufacturing, which centers on creating collaborative project teams and an environment “unlimited by aversion to risk,” where “dreaming it” and “building it” is not only possible, but is said to be standard operating procedure. Scaled Composites was founded by Burt Rutan, one of the few people to receive achievement awards from both ACMA and SAMPE. concrete foundation wall. They don’t crack, they don’t leak and they provide a superior product at a price that is competitive to current residential building practices. Polystrand entered an automotive suspension that showcases the use of continuous fiber-reinforced thermoplastic springs and control arms. The concept can be easily adapted for use in OEM automotive applications and features lightweight, recyclable technology. The cantilever springs and control arms, made of continuous glass-reinforced nylon, can serve simultaneously as springs and structural components, saving weight and allowing consolidation of parts. Since the upper control arms are also flexible members, they are coupled together in this application to counteract body roll during cornering, while increasing roll-induced camber gain, which can be beneficial in this racing application. In passenger car applications, this technique can reduce body roll without adversely affecting straight-line ride comfort. EXHIBIT HOURS WhiteKnightTwo/Virgin MotherShip Eve is designed to ferry SpaceShipTwo for part of its journey into orbit. Virgin Galactic’s SpaceShipTwo, developed and manufactured by Scaled Composites, will carry passengers into low-Earth orbit. Tuesday, October 14 11 a.m. to 5 p.m. Wednesday, October 15 9:30 a.m. to 5 p.m. Thursday, October 16 9:30 a.m. to 12 p.m. Train for Tomorrow – Certify for Success CCT Benefits for Companies CCT Benefits for Individuals • Increased productivity • Documentation of professional expertise • Lower production costs • More skilled, forward-looking workforce • Industry-wide recognition of skills • Enhanced career opportunities Designations Cast Polymer Light Resin Transfer Molding Compression Molding Open Molding Corrosion Vacuum Infusion Process Instructor Wind Blade Repair www.compositescertification.org 8 Tuesday, October 14, 2014 The Industry’s Gold Standard for Composites Training Product News at CAMX 2014 Composite curing batch ovens Wisconsin Oven Corp. (East Troy, Wis.) is emphasizing its line of electrically heated, gas-fired and indirect gas-fired composite curing batch ovens in Booth 1545. Wisconsin Oven says its ovens offer several advantages in composite curing applications: • Quick heating rates and recovery times: Each oven features a high-pressure recirculation blower, which includes fully enclosed and pressurized supply ducts. It’s designed for combination airflow arrangement, which is said to ensure even and uniform heat distribution throughout the work chamber, even with varying loads. • Consistent temperature certification: Composite curing ovens are typically guaranteed and certified for ±10°F at 350°F temperature uniformity. Tighter tolerances and certification at other temperatures are available. Equipment is completely tested prior to shipment and must pass a 154-point quality inspection prior to shipment. • Energy efficiency: Ovens are available with the E-Pack Oven upgrade. This optional upgrade package includes thicker wall panels, higher efficiency motors and other energy-saving features. Wisconsin Oven Corp., Booth 1545 Polyphenylsulfone foam core, thermoplastic resins Solvay Specialty Polymers (Alpharetta, Ga.) introduces Radel PPSU foam, said to be the industry’s first thermoformable polyphenylsulfone (PPSU) foam for insulative and structural components used in aircraft interiors, in Booth 3069. Positioned as an alternative core material to honeycomb, Radel PPSU foam reportedly lends itself to high-productivity manufacturing of sandwich structures with consistent quality at attractive economics. High-performance PPSU foam is based on Solvay’s Radel PPSU, a super-tough thermoplastic resin used for more than 20 years in structural and decorative aircraft interior applications. Radel PPSU foam is used in commercial applications in the Airbus A350 XWB aircraft. For cores and ducting, Solvay is also highlighting Solef PVDF foam, which can be molded into complex 3-D shapes that offer excellent flame/smoke/toxicity (FST) performance, toughness, resiliency, excellent resistance to aerospace fluids and mechanical properties to 120°C/248°F. Solef 3-D molded foam also permits the production of parts with zero scrap and eliminates the need for interior insulation. Solvay will discuss the use of Ajedium Films made from fluoropolymers, engineering polymers, and high-performance polymers for production of thermal acoustic insulation blankets. Films made using ethylene chlorotrifluoroethylene (ECTFE), polyvinylidene fluoride (PVDF), polyetheretherketone (PEEK), and polyaryletherketone (PAEK) provide uniform release from composites and other substrates under pressure, heat or other demanding conditions. Lightweight Halar ECTFE film is used in the Solar Impulse solar-powered airplane to weather-proof photovoltaic cells without compromising light transmission. Rounding out Solvay’s offering for composites are a range of thermoplastic resins including KetaSpire PEEK, which combines good chemical resistance and long-term thermal and mechanical stability with strength, stiffness and fatigue resistance. AvaSpire PAEK, a family of polymers tailored to provide new and unique combinations of thermal, mechanical and chemical performance while exhibiting superior processing characteristics compared to PEKK and PEK. Through fiber loading and mixed composite/overmolding techniques, Solvay’s KetaSpire PEEK and AvaSpire PAEK compounds reportedly push short fiber solutions ever closer to composites while ensuring simpler processing and cost savings. Typical applications are fixtures and clips. Solvay Specialty Polymers, Booth 3069 Continuous carbon fiber/ thermoplastic 3-D printing MarkForged (Cambridge, Mass.) is featuring the Mark One, an additive manufacturing (AM) 3-D printer that produces parts made with continuous carbon fiber in a thermoplastic resin. On display in Booth 1533, the Mark One has two print heads, both designed and built by the company. One dispenses polyamide (nylon) or polylactide (PLA) resin, and the second dispenses a continuous towpreg, either carbon or glass (dispensing of aramid fiber is in development). The towpreg is made in a proprietary process: A single carbon filament is coated with a specially developed thermoplastic resin, designed specifically for the printer. The Mark One uses fused deposition modeling (FDM), an extrusion-like process, for placement of resin and towpreg in the flat x/y plane of the part. The company says that the fiber can be oriented, or added selectively only where needed, in the x/y plane, but notes that, at present, vertical, or z-directional, orientations aren’t possible. Each build layer is approximately 200 µm thick. The “stage” on which deposition takes place is a plastic platform, to which the polyamide or PLA resin adheres, similar to other AM machines. The finished part is scraped off when finished and the platform lasts for roughly 100 prints. Unique to the Mark One is the use of a highprecision “kinematic coupling” to precisely level and fix the build platform. Used in silicon wafer processing, the coupling precisely constrains all six degrees of freedom so that the build stage can simply be “clicked” into place. Set-to-reset leveling is reportedly repeatable to within 10 µm. MarkForged, Booth 1533 www.theCAMX.org/mobile 9 THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Infusion bagging supplies and equipment Infusion specialist Airtech International (Huntington Beach, Calif.) is featuring several products in Booth 4529: • Airflow 100R, a durable high-temperature and high-pressure autoclave hose, is now available with 90° fixed end fittings on one or both ends. The silicone rubber outer protective sleeve encases braided stainless steel covering a PTFE inner tube supported with a flexible steel spring conduit. Its design prevents collapse from vacuum or autoclave pressures. • Vac-Gauge 40D is a versatile digital vacuum gauge used for leak detection and vacuum determinations under the vacuum bag. The gauge offers vacuum readings in four selectable units: mBar, mmHg, inHg, and Kpa. • Airtech Vacuum Test Unit is a compact, lightweight and reportedly easy-to-use device to test in-service equipment or to check equipment that has undergone maintenance, like seal replacements on vacuum valves or end fitting replacements on Intellectual property protection Investigative and analysis specialist CHEMIR’s (Maryland Heights, Mo.) analytical experts and Canadian law firm Gowlings’ (Ottawa, Ontario, Canada) patent law experts are delivering a technical presentation titled “Intellectual Property Considerations and Strategy in New Product Development” on Wednesday, Oct. 15, at 8 a.m. in W223 A/B. Anita Nador will discuss the legal implications of conducting research on patented products, the first sale doctrine and reverse engineering (also known as deformulation) of a patented product, both from the perspective of a new market entrant and a patent owner. Nador is a partner and registered U.S. and Canadian patent agent specializing in chemical and life sciences related patents at Gowlings. Dr. Albert Lee and Aaron Cassely, both scientists from CHEMIR, will present a case study of an adhesive deformulation to further illustrate these challenges. CHEMIR is exhibiting in booth 1576. CHEMIR, Booth 1576 Composites design engineering software Altair Engineering Inc. (Troy, Mich.) is featuring its HyperWorks suite of composites design engineering tools in Booth 3661. The software applies to laminated, woven and chopped fiber composites and is based upon finite element methods in conjunction with optimization algorithms to provide design guidance and insights. HyperMesh allows composites data to be read from the CAD model, with ply shapes and parameters comprehended and mapped 10 Tuesday, October 14, 2014 onto elements. It uses ply-based modeling and has the ability to convert from ply- to zone-based modeling for solvers that do not natively support ply-based modeling. HyperView provides layerbased postprocessing for composites, yielding results for individual layers and the aggregation of layers, identifying the maximum contributing layer. OptiStruct is a solver with nonlinear capabilities for ply-based modeling. It offers size optimization for dimensioning of structural components, as well as topology optimization to reduce weight by determining the ideal material distribution. Altair also offers access to the Altair Partner Alliance (APA), which enables HyperWorks users to call on third-party software as needed at no additional cost. Nine software tools for designing and analyzing composites are available through the APA, including AlphaStar, Componeering and ESRD. Altair Engineering Inc., Booth 3661 vacuum hoses. • Airpad HTX is an uncured nonsilicone rubber that can be made into caul sheets and flexible mandrels. • Toolwright 3 and Toolwright 5 are extruded fluoropolymer films coated with silicone pressure-sensitive adhesive. The yellow color is highly visible on most substrates; the material offers high elongation and tensile strength. • Wrightlease 2 is an extruded fluoropolymer film coated with silicone pressure-sensitive adhesive. The orange color is highly visible on most substrates; the material offers high elongation and tensile strength. Wrightlease 2R has the same features as Wrightlease 2, but is rubber-based and light green. Airtech International, Booth 4529 Lightning strike materials and protection Lightning strike specialist Dexmet’s (Wallingford, Conn.) expanded lightning strike division is offering MicroGrid precision expanded metal foils to makers of composite materials for lightning strike protection. MicroGrid’s single unit structure is said to be superior to woven material in that it won’t unravel or produce loose strands that become problematic during processing into a prepreg material or when conducting a dry layup. The homogeneous design also reportedly ensures uncompromised conductivity between strands when forming the material to a variety of shapes and contours, and provides a smooth surface on the end product. Dexmet says the biggest advantage of MicroGrid is the company’s ability to tightly control the manufacturing process to meet a specific weight, open area and conductivity requirement. Dexmet says its precision expanded metals and polymers allow engineers the option of varying materials according to specific strike zones on the aircraft or structure, while adding little weight to the aircraft or structure. Also, printed copies of Dexmet’s 12-page technical papers are available in Booth 3483. Dexmet, Booth 3483 M 3 B a p a (F c sp y w 2 Product News at CAMX 2014 Composites automation programming software Simulation and machining software specialist CGTech (Irvine, Calif.) demonstrates the process of programming automated composite machinery. Visitors to Booth 3656 can see the steps needed to get from a CAD-designed composite part to CNC programs that drive an automated fiber placement (AFP) or automated tape laying (ATL) machine. CGTech is also demonstrating VERICUT composite applications, including VERICUT Composite Paths for Engineering (VCPe), VERICUT Composite Programming (VCP) and Vericut Composite Simulation (VCS). VCPe measures and evaluates the effects of AFP and ATL path trajectory, material steering, surface curvature, course convergence and other process constraints as they would be applied in manufacturing. It also provides produceability analysis of the fiber angle based on the curvature of the part and overlap and gaps needed for structural analysis. VCP reads CATIA V5, STEP or ACIS surface models. It also reads Fibersim, CATIA V5, or other external ply geometry and information. VCP then adds material to fill the plies according to user-specified manufacturing standards and requirements. Layup paths are linked together to form specific layup sequences and are output as NC programs for the automated layup machine. VCS reads CAD models and NC programs, either from VCP or other composite layup path-generation applications, and simulates the sequence of NC programs on a virtual machine. Material is applied to the layup form via NC program instructions in a virtual CNC simulation environment. The simulated material applied to the form can be measured and inspected to ensure the NC program follows manufacturing standards and requirements. CGTech is also exhibiting its latest version of VERICUT. VERICUT is CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving-out NC programs. VERICUT simulates all types of CNC machining, including drilling and trimming, waterjet, riveting, robotics, mill/turn, and parallel kinematics. CGTech, Booth 3656 MEET THE MARK ONE™: THE WORLD’S FIRST COMPOSITE 3D PRINTER. 3D PRINT CARBON FIBER. Brilliant ideas need brilliant materials. The Mark One™ uses a patent pending Composite Filament Fabrication (CFF™) process to 3D print continuous strand carbon fiber, Kevlar®, and fiberglass. Utilizing the CFF™ print head and one FFF (Fused Filament Fabrication) print head, the Mark One can create astonishingly robust parts by reinforcing MarkForged’s special blend of nylon with continuous fiber filaments. Now you can 3D print functional parts with a higher strength-toweight ratio than 6061-T6 aluminum – at your desk. VISIT US AT BOOTH 1533 Kevlar® is a registered trademark of DuPont E.I. du Pont de Nemours and Company or its affiliates. 20x stiffer than ABS. 5x stronger than ABS. Carbon Fiber • Kevlar® • Fiberglass Nylon • PLA 11 www.theCAMX.org/mobile LEARN MORE AT MARKFORGED.COM THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Closed molding materials and demonstrations Hot-melt prepreg machines Composites One (Arlington Heights, Ill.) is emphasizing the launch of its all-new website compositesone.com, live closed mold demonstrations and two technical presentations. Visitors can see the new site live at workstations in the Composites One Booth 2570. They can navigate through the site and provide feedback to Composites One team members. A mobile version is also available for those who prefer to use their phones to search for product or process information. Composites One and the Closed Mold Alliance are presenting the Lean Mean Closed Mold Machine demonstration live on the CAMX exhibit hall floor in Booth 2772. This year, the event has been dubbed the Super Demo and features five industry segmented demonstrations and one presentation focused on new technology. The featured market segments are marine, oil and gas, wind energy, aerospace, and transportation/automotive. The demos feature closed mold processes like light resin transfer molding (LRTM), vacuum infusion and reusable silicone bag molding. The demonstration also includes prepreg on two large parts, cured using an oven supplied by Wisconsin Oven, also a CAMX exhibitor in Booth 1545. Products, In Booth 2949, C. A. Litzler Co. Inc. (Cleveland, Ohio) is featuring its latest technology in hot melt prepreg machines. Litzler designs hot melt prepreg equipment for the production of high-quality unidirectional and woven prepregs. These machines include systems for development and production systems in widths ranging from 12 inches to 60 inches (305 mm to 1,524 mm). Machines include online and offline filmers as well as a patent-pending thermoplastic prepreg unit. Litzler’s prepreggers are designed with the S-wrap prepreg process, which can increase production up to 100 ft/ min on a standard machine. Litzler says typical competing designs are only useful to 15 ft/min. Litzler celebrates 61 years in business in 2014. C. A. Litzler Co. Inc., Booth 2949 including many high-performance solutions, featured in the demonstration are provided by partners: 3A Composites, AOC Resins, Airtech International, Arekma, CCP Composites, ChemTrend, Chomarat, ITW Plexus, Huntsman, Magnum Venus Plastech, Owens Corning, Sworl, United Initiators and Vectorply Corporation with tooling provided by Airtech International, Carbon Craft, RTM Solutions and VX Aerospace. In addition to the website launch and the live demonstration, Composites One is presenting two technical sessions at CAMX 2014. The first is a technical paper titled “A Composite Manufacturer’s Decision Process Leading to Silicone Vacuum Bag Selection,” to be presented by James Noonan, technical support manager at Composites One, Tuesday, Oct. 14, 3 p.m., in W224 C. The second session, “Optimizing Surface Finish for Closed Molding,” is a panel discussion featuring Composites One supplier partners and is moderated by Noonan, Wednesday, Oct. 15, 10 a.m., also in W224 C. Composites One, Booth 2570 NPE2015: THE INTERNATIONAL PLASTICS SHOWCASE March 23-27, 2015 | Orange County Convention Center Orlando | Florida USA You have questions. We have answers. In today’s rapidly changing business environment, having a full understanding of the issues that impact your company’s decision-making is critical in order to remain successful. SPI’s Business of Plastics Conference, featuring sessions from ACMA, is designed to provide in-depth knowledge and education around the latest topics and newest trends—including thermoplastics composites manufacturing—important to growing your business. Get answers to the market’s tough challenges. Register for the SPI Business of Plastics Conference at npe.org BUSINESS OF PLASTICS CONFERENCE 12 Tuesday, October 14, 2014 A M E R I C A N C O M P O S I T E S M A N U FA C T U R E R S A S S O C I AT I O N 5-axis overhead gantry CNC router In Booth 4345, CNC specialist Diversified Machine Systems (DMS, Colorado Springs, Colo.) exhibits DMS D5E, an enclosed 5-axis overhead gantry CNC router with twin moving tables, customized for composites machining. It features a Fagor 8055i CNC, solid 2-ft by 3-ft (0.6m to 0.9m) twin tables and 30-inch/762-mm Z stroke. It is said to be the first machine of its kind to offer a glass clam shell-style roof on a smaller unit. Other features include airborne debris containment, a dual-table workspace and footprint efficiencies that are said to be in demand globally. Diversified Machine Systems (DMS), Booth 4345 Product News at CAMX 2014 Oxidizer for carbon fiber manufacturing Anguil Environmental Systems Inc. (Milwaukee, Wis.) is emphasizing its oxidizers for abating emissions in the manufacture of carbon fiber in Booth 4069. Oxidation and carbonization furnaces and industrial ovens have the potential to emit hydrogen cyanide (HCN), ammonia (NH3) and volatile organic compounds (VOCs). Some of these pollutants are immediately dangerous to human health, even in very small quantities. Other pollutants of concern for carbon fiber producers include harmful gases such as carbon monoxide (CO) and nitrogen oxide (NOX). These emissions not only contribute to global warming but also have a direct correlation with the manufacturer’s consumption of energy. Anguil is emphasizing two recent oxidizer installations, one at the University of Nottingham (Nottingham, U.K.) and one at Oak Ridge National Laboratories (ORNL, Oak Ridge, Tenn.). The University of Nottingham is working with The Boeing Co. (Chicago, Ill.) on carbon fiber recycling and has developed a pilot scale carbon fiber recycling plant. The team at Nottingham knew that an air pollution control device would be necessary to meet the local emission requirements, but also realized that there was the potential to reuse some of the energy released during the combustion of carbon fiber processing emissions. Anguil was selected to provide the air pollution control system for the University of Nottingham. The company manufactured, installed and recently brought online a Thermal Recuperative Oxidizer with dual heat recovery. A similar system was implemented at ORNL, where the U.S. Department of Energy has built a pilot scale carbon fiber manufacturing line. To treat the exhaust streams coming from the carbon fiber process, Anguil Environmental Systems was commissioned to design, manufacture and install a multistage Direct Fired Thermal Oxidizer (DFTO). The abatement system is capable of destroying nitrogen compounds without the formation of NOX. Gases move through zones within the DFTO under varying conditions where the total emission destruction efficiencies exceed 99 percent with minimal NOX generation. Anguil Environmental Systems Inc., Booth 4069 Wetting aids, dispersants, coupling agents Additives specialist BYK USA (Wallingford, Conn.) is featuring its line of wetting aids, dispersants and coupling agents to improve glass, carbon and natural fiber composites in Booth 2063. Products include air release additives and defoamers, VOC and odor control solutions, scratch and mar control, pigment and filler dispersants, and organo-modified clays for control of rheology, melt strength, dimensional stability and mechanical properties. Garamite additives reportedly differ from other organically modified mineral thixotropes by exhibiting ease of dispersion, ease of use, high efficiency and high performance without unwanted viscosity. BYK-R 607 is a new thixotropy booster for epoxy and high-polarity, solvent-borne systems. BYK-R 607 is said to provide good antisagging, antisettling and antisyneresis properties. BYK USA, Booth 2063 Save the Date! Baltimore Convention Center Baltimore, Maryland, USA May 18-21, 2015: Conference | May 19-20, 2015: Exhibits SAMPE is now accepting abstracts for SAMPE Baltimore 2015 ► Abstracts are due by October 24, 2014. ► If your abstract is accepted, Technical Papers are due no later than January 16, 2015. COMBINED STRENGTH. UNSURPASSED INNOVATION. SUBMIT YOUR ABSTRACT TODAY October 26-29, 2015: Conference October 27-29, 2015: Exhibits Dallas Convention Center Dallas, Texas, USA www.theCAMX.org Produced by www.sampebaltimore.org www.theCAMX.org/mobile 13 THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Carbon fibers, tooling materials, fabric forms and prepregs In Booth 2855, fiber and resins supplier Hexcel (Stamford, Conn.) is featuring HexTow HM63 carbon fiber, HexTool composite tooling, PrimeTex spread-tow carbon fiber fabric, HiTape dry carbon fiber reinforcements, HexPly M77 snap-cure prepreg and HexPly M79 prepreg. HexTow HM63 carbon fiber offers what Hexcel says is the highest tensile strength of any high-modulus fiber, providing good translation of fiber properties in a composite, including what is said to be superior interlaminar shear and compression strength. HexTow HM63 is suitable for any high-stiffness and strength-critical applications including space, satellites, unmanned aerial vehicles (UAV), commercial aerospace and helicopters. It also meets the requirements for premium sports and recreation applications including F1, marine craft, bikes and fishing rods. Hexcel is displaying tooling manufactured by Sawyer Composites using HexTool M61. HexTool composite tooling material is said to provide the ability to meet strict requirements for stability and repeatability of tolerances previously accomplished by machined Invar tools, in addition to improved thermal performance and reduced weight of carbon tools over metal tools. The tooling produced by Sawyer Composites is used by CFAN to make the fan blades for the GE90 and GEnx engines. PrimeTex carbon fiber fabrics feature fibers spread in the warp and weft direction to provide a uniform weave and gap-free finish. The PrimeTex spreading process is said to increase the closure factor by 5 to 8 percent compared to conventional weaving processes (depending on the carbon tow and FAW). PrimeTex fabrics are designed for aerospace laminates as the gap-free structure reduces porosity and requires less part finishing. HiTape advanced dry carbon fiber reinforcements combine the benefits of automated processing with the cost effectiveness of out-of-autoclave (OOA) infusion technologies. HiTape allows preforms to be manufactured in a fully automated layup process, with high deposition rates. When infused with HexFlow resins, HiTape parts can be as thick as 30 mm with a 58 COMBINED STRENGTH. UNSURPASSED INNOVATION. October 13-16, 2014: Conference / October 14-16, 2014: Exhibits Elite Sponsors Supporter Sponsors Contributor Sponsors 14 Tuesday, October 14, 2014 to 60 percent fiber volume fraction, resulting in mechanical properties that are as high as those achieved with primary structure prepregs. To demonstrate the potential of HiTape for cost and cycle efficient primary aircraft structures, Hexcel has worked with Aerolia SAS and Coriolis Composites to design and manufacture an aircraft fuselage panel demonstrator that is on display. For automotive, HexPly M77 snap cure prepreg has a 2-minute cycle at 150°C/302°F (80 bar pressure). The low tack of HexPly M77 enables the prepreg to be cut into precise shapes by laser cutter, then oriented, assembled and consolidated into flat preforms by robot. The high Tg of 125°C/257°F enables the cured parts can be demolded while hot for a faster production cycle. HexPly M79 prepreg was developed to meet industry requirements for a faster and lower temperature curing prepreg for thick laminates in the wind energy and marine industries. It will cure in 8 to 10 hours at 70°C/158°F or in just 4 to 6 hours at 80°C/176°F. On Hexcel’s stand at CAMX, visitors can see a carbon fiber laminate consisting of 695 plies of HexPly M79 600-g/m2 carbon unidirectional tape that cured in just 6 hours at 80°C/176°F. Hexcel, Booth 2855 Make it Precision Board Plus High Density Polyurethane Tooling Board and Core Material • Custom tooling blocks • Closed cell structure • Custom carving blocks • No out-gassing • Custom mandrels • 15 standard densities • Exceeds aviation flammability standards • 8 sheet sizes up to 24” thick (800) 845-0745 www.precisionboard.com Visit us at CAMX Orlando Oct. 14-16 Booth #4157 LOOK! It’s Vacuum Infusion. It’s Reusable Bag Molding. It’s Light RTM. It’s Prepreg. IT’S ALL THAT AND MORE! THE NEXT GENERATION LEAN MEAN CLOSED MOLD MACHINE 5 demos, 5 parts, 5 markets, 5 times the value! Plus a new technology and the latest high performance materials! IT’S SUPER DEMO 5 TIMES MORE POWERFUL! see it LIVE at Booth #2772 during CAMX 2014 in Orlando, October 14-16 Brought to you by Composites One and the Closed Mold Alliance along with our industry partners

© Copyright 2026