Welcome to the Reception THURSDAY, OCTOBER 16, 2014 Panel assesses thermoplastics potential:

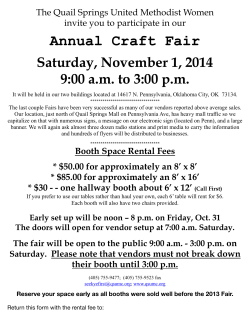

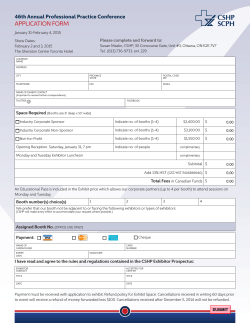

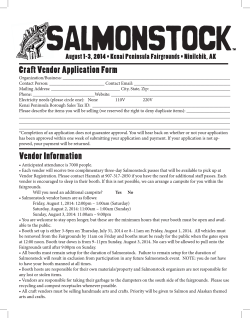

THURSDAY, OCTOBER 16, 2014 IN ASSOCIATION WITH Orlando, Florida | Orange County Convention Center Panel assesses thermoplastics potential: www.theCAMX.org/mobile Welcome to the Reception Thermoplastic composites are an option now more than ever. Material experts weigh in on the potential. PG 5 ACMA membership awards: ACMA’s outstanding members to be recognized today at Awards Luncheon. PG 7 On-the-floor highlights: An overview of product and technology highlights from the CAMX Exhibit Hall. PG 8 Products and services in the Exhibit Hall: With more than 550 exhibitors, there is an abundance of new products and technologies to be found on the CAMX show floor. PG 10 EVENTS NOT TO MISS • Exhibit Hall Open TIME: 9:30 a.m. - 12:00 p.m. • ACMA Awards Luncheon TIME: 12:00 p.m. - 2:00 p.m. Valencia Ballroom A/B - 4th Level • SAMPE Awards Luncheon TIME: 12:00 p.m. - 2:00 p.m. Valencia Ballroom C/D - 4th Level Several hundred attendees and exhibitors gathered for the CAMX Welcome Reception in the Convention Center to celebrate the inaugural event. Sigmatex announces second U.S. plant Carbon fiber textiles specialist Sigmatex Ltd. (Runcorn, Cheshire, U.K.) announced on Wednesday that it will build a new $12 million manufacturing facility in Orangeburg County, S.C. The investment is one of the largest capital investment projects the company has undertaken. The facility is expected to begin operation by mid-2015. The new 75,000-ft2/6,967m2 facility will be constructed to allow for expansion to 150,000 ft2/ 13,935m2 and eventually 450,000 ft2/41,806m2 to accommodate potential growth in aerospace and automotive. “We are very excited to be building our latest manufacturing facility in South Carolina. This will be our second, and largest, in North America, representing a major step in our commitment to global expansion,” said CEO Scott Tolson. Demos focus of CAMX The centerpiece of demonstration activity at the show is the Composites One demonstration area, located adjacent to the Composites One exhibit at Booth 2570. It features, each day, demonstrations of hand layup, infusion and light resin transfer molding (LRTM). End markets expressed include aerospace, automotive, wind, and oil and gas. Wednesday morning’s infusion demonstration garnered a small crowd as Neil Smith, technical service manager at Composites One, walked attendees through a tutorial of the theory of infusion molding, materials required, equipment used and best practices. This includes the basics of fiber permeability, pressure gradients, resin viscosity, flow front behavior, resin injection location, infusion media, race-tracking, bridging, back pressure management, post-cure requirements and more. Composites One has, in the demo area, a Wisconsin Oven for curing operations. See page 4 for a complete list of CAMX demonstrations. ACE and CAMX Awards formally presented today By Jeff Sloan CompositesWorld Magazine compositesworld.com The winners of the Awards for Composites Excellence (ACE) and the CAMX Awards are being formally presented at the ACMA luncheon today, 12-1:30 p.m. in the Valencia Ballroom, fourth level of the Convention Center. ACE winners cover six categories, two each for design, manufacturing and market growth. CAMX Awards are given for two categories, collaboration and teamwork, and unsurpassed innovation. The winners are listed below. There is a double-winner this year: Composite Panel Systems LLC won an ACE in Infinite Possibility Market Growth, as well as a CAMX Award for unsurpassed innovation. ACE Design: Innovation in Green Composites Design Award: Blackbird Ukulele, submitted by Blackbird Guitars. Blackbird’s Clara is a concert-sized See ACE and CAMX Awards, continued on page 3 Make it Precision Board Plus High Density Polyurethane Tooling Board and Core Material • Custom tooling blocks • Closed cell structure • Custom carving blocks • No out-gassing • Custom mandrels • 15 standard densities • Exceeds aviation flammability standards • 8 sheet sizes up to 24” thick (800) 845-0745 www.precisionboard.com Visit us at CAMX Orlando Oct. 14-16 Booth #4157 ACE and CAMX Awards, continued from page 1 composite ukulele, fabricated from Ekoa, a lighter-than-carbon, renewable flax/ bioresin prepreg developed by Blackbird and Lingrove. The Clara offers concertquality sound and vintage look in a woodfree, sustainable package. The high-performance hollow-neck, uni-body construction is free of the durability and weather stability issues suffered by wooden instruments. This bio-based solution is tuned to sound like a Stradivarius, but is unusually strong and thus offers an alternative to cutting down old-growth trees. Design: Most Creative Application Award: Stranded Composite Core for High-Voltage Transmission Conductors, submitted by Celanese Corp. Celanese Corp. and Southwire Co. LLC have worked together to create an innovative High Tensile, Low Sag (HTLS) high-voltage overhead transmission conductor, using a continuous thermoplastic carbon fiber-reinforced composite core to replace steel-reinforced conductors. The composite assembly is the strength member for the overhead conductor. The composite core consists of seven Celstran CFR-TPR continuous carbon fiber-reinforced/ polyphenylene sulfide (PPS) thermoplastic composite rods. Each composite rod is uniformly “capped” with a layer of high-performance polyetheretherketone (PEEK) to provide abrasion and wear resistance, improved operating temperatures, and protection against galvanic corrosion. Thermal expansion becomes almost negligible with the composite core because of the very low coefficient of thermal expansion of carbon fiber. Mechanical sag is minimized by the composite core due to its high strength-to-weight ratio. IN ASSOCIATION WITH Orlando, Florida County Center Orlando, Florida| Orange | Orange CountyConvention Con- www.theCAMX.org/mobile www.theCAMX.org/mobile SHOWDAILY STAFF CONTRIBUTORS CompositesWorld Magazine Jeff Sloan, Editor-In-Chief Mike Musselman, Managing Editor Sara Black, Technical Editor Ginger Gardiner, Senior Editor Rick Kline Jr., Group Publisher Ryan Delahanty, Publisher Kim Hoodin, Marketing Director Barb Businger, District Manager Rick Brandt, District Manager Eddie Kania, European Sales Manager SHOWDAILY PRODUCTION Rhonda Weaver, Production Manager Stephanie Monsanty, Editor Jeff Norgord, Art Director/Photographer Becky Helton, Advertising Manager The CAMX ShowDaily is published by Gardner Business Media, Inc. 6915 Valley Ave., Cincinnati, OH 45244 © 2014 by Gardner Business Media, Inc. Manufacturing: Equipment and Tooling Innovation Award: Near Dripless Resin Impregnation for Filament Winding, submitted by TSE Industries Inc. TSE has developed a new method of reinforcement impregnation during filament winding. This method not only minimizes process waste, but also maximizes the effective impregnation of reinforcement strands using minimal quantities of resin. TSE’s patented technology ensures better laminate quality through consistent impregnation. Not only can the roving tension be automatically controlled, but the ratio of reinforcement to resin (LOI) can also be easily and consistently controlled. The near dripless applicator helps optimize resin impregnation, consistently providing a 70 to 80 percent glass-to-resin ratio. Manufacturing: Material and Process Innovation Award: 3-D Printing Continuous Strand Carbon Fiber, Glass Fiber and Kevlar Composites, submitted by MarkForged. MarkForged’s Mark One 3-D printer is the first 3-D printer designed to print continuous carbon fiber, Kevlar and fiberglass. Using a patent-pending Composite Filament Fabrication (CFF) process, MarkForged’s blend of thermoplastics immediately hardens during printing. CFF offers the opportunity to dramatically shorten design cycles and enables high-resolution fiber placement. The system uses a proprietary thermoplastic matrix that also offers good interlayer adhesion and high impact resistance not found in thermosetting resins. Based on in-house three-point bending tests, Mark One carbon fiber CFF 3-D-printed beams have a higher strength-to-weight (specific modulus) than 6061 T6 aluminum. Further, the user can easily turn billet parts into sandwich panels with printed-in core material, increasing strength-to-weight while adding panel stiffness to external facing components. Market Growth: Composites Sustainability Award: Lightweight Composite Air Cargo Container, submitted by Cargo Composites. Cargo Composites’ AeroBox is a lightweight 58-kg/123-lb air cargo container used in the belly of wide-body aircraft to transport baggage, mail and cargo. The low weight of this unit saves approximately $1,250 per year in fuel and 7,800 kg/17,196 lb of CO2 emissions compared to the 82-kg/181-kg aluminum container it replaces. The thermoplastic composite honeycomb panels not only produce a lighter structure, but greatly improve durability. Repair rates of this material in a rough handling environment are one-quarter those of aluminum, leading to a lower lifecycle cost. The 100 percent recyclable panels are thermoformed at the edges to create a structural corner when assembled, eliminating the need for damage-prone aluminum extrusions and reducing the overall parts count. The estimated annual total fuel savings for the 18,000 containers now flying worldwide is more than 25 million liters/6.6 million gal and CO2 savings are 1,476 metric tons/3.25 million lb. Market Growth: Infinite Possibility for Market Growth Award: Epitome Quality Foundation Walls, submitted by Composite Panel Systems LLC. Composite Panel Systems LLC’s Epitome Quality Foundation Walls are a composite alternative to traditional concrete residential foundations. The sandwich panel construction of Epitome foundation walls provides the homeowner with a warmer, drier and healthier living space (R-16.5 insulation value), as well as improved flexibility to modify or finish the basement. For the builder, Epitome foundation walls combine structure, integrated stud cavities for mechanicals, top plate and damp proofing into a single step. Further, the builder can now install a typical foundation in less than two hours. Moreover, Epitome foundation walls can withstand three times the backfill load of a standard concrete foundation wall. CAMX Combined Strength Award: NASA-Boeing Composite Cryotank Technologies & Demonstration Team, submitted by NASA Glenn Research. NASA Glenn Research submitted the NASA Composite Cryotank Technology Demonstrator. NASA collaborated with Boeing to design, fabricate and test an all-composite cryogenic fuel tank for launch vehicles, paving the way for lower-cost access to space. These designs achieved a 30 percent weight savings and a 25 percent cost savings, allowing insertion of higher mass payloads to low-Earth orbit (LEO) and beyond. A number of technology firsts included thin-ply fiber placement of a large test article (5.5m/18-ft diameter) using out-of-autoclave (OOA) processing, and successful cure of a hybrid (thick and thin plies) laminate. Ultimately, the largest automated fiber placement (AFP), OOA composite tank was fabricated as a result of this effort. It was also the first successful demonstration of an all-composite bolted sump/forward cover joint. NASA analytical capabilities facilitated the rapid development of models for AFP processes, and accurate prediction of structural response in a series of tests using liquid hydrogen (LH2) to thermally cycle the composite tank through various pressure ranges. Unsurpassed Innovation Award: Epitome Quality Foundation Walls, submitted by Composite Panel Systems LLC. See description, above. Congratulations to the winners. All ACE and CAMX Awards entries can be seen in the Awards Pavilion in the CAMX Exhibit Hall. www.theCAMX.org/mobile 3 THE COMPOSITES AND ADVANCED MATERIALS EXPO CAMX shuttle bus schedule The Convention Center shuttle bus stops are located in the main bus drop-off area between the Exhibit Hall C Lobby area and Conference Program Rooms W224. If you require an ADA shuttle bus or would like additional information, call 310-466-4699. (Call at least 30 minutes prior to desired pickup time if an ADA bus is required.) Hotel Route BUS ROUTE HOTEL HOTEL SHUTTLE BOARDING LOCATION Avanti Resort 1 Curbside, International Dr. Courtyard Orlando International Drive 1 Curbside, Austrian Ct. Embassy Suites Orlando — International Drive South 1 I-Ride Trolley Stop 22, International Dr. Rosen Inn Pointe Orlando 1 Curbside, International Dr. Hampton Inn Orlando 2 Walk to Springhill Suites, curbside, Universal Blvd. Homewood Suites by Hilton Orlando 2 Walk to Springhill Suites, curbside, Universal Blvd. Hyatt Place Orlando/Convention Center 2 Walk to Springhill Suites, curbside, Universal Blvd. Residence Inn Orlando Convention Center 2 Walk to Springhill Suites, curbside, Universal Blvd. Springhill Suites Orlando Convention Center 2 Curbside, Universal Blvd. DoubleTree 3 Outside of main lobby Hours of Shuttle Bus Service* Tuesday, Oct. 14 7:00 a.m.-7:00 p.m. Every 10-15 minutes Wednesday, Oct. 15 7:00 a.m.-10:00 a.m. Every 10-15 minutes 10:00 a.m.-3:00 p.m. Every 30 minutes 3:00 p.m.-7:00 p.m. Every 10-15 minutes 7:00 a.m.-2:00 p.m. Every 10-15 minutes 2:00 p.m.-6:00 p.m. Every 30 minutes Thursday, Oct. 16 *Shuttle departs Convention Center on the hour and half hour. Schedule may vary due to traffic and weather conditions. Last bus leaves from hotel 30 minutes prior to end time with no return service. CAMX on-floor demonstrations • NETZSCH Instruments, Booth 1643: There is no shortage of actual manufacMaterial analysis instruments turing taking place at CAMX, some of it • RocTool, Booth 4365: High-speed designed to highlight capability, some injection, heating, cooling of it to educate composite professionals • Sandvik Process Systems, Booth 3768: on manufacturing processing methods. Continuous process systems Whatever your level of interest, there are • SWORL, Booth 3261: Reusable vacuum several manufacturing demonstration membranes options on the show floor. Below is a list of exhibitors that have reported they are offering demonstrations: • A&P Technology, Booth 2447: Fiber reinforcement and braided products • Composites One, Booth 2570: Closed molding processes • Entec Composite Machines, Booth 3561: High-speed filament winding • MarkForged, Booth Neil Smith, a technical service manager at Composites One, 1533: Continuous fiber explains the theory, best practices and basics of infusion molding materials and technology Wednesday morning in the Exhibit Hall. additive manufacturing 4 Thursday, October 16, 2014 Student poster winner The winner of the CAMX Poster Session Competition was “Reverse the Curse of the Nylon Peel Ply?,” presented by Ashley Tracey at the University of Washington. The runners up were: “A Holistic Approach to Composite Recycling,” University of Alabama at Birmingham; “Improved Analysis of Nano-Composite Sensing Materials,” Brigham Young University; “Triboluminescent Sensor for Distributed Damage Monitoring in Composites: Wind Turbine Blade Application,” Florida A&M-Florida State University College of Engineering. Thermoplastics reviewed at SAMPE panel By Sara Black CompositesWorld Magazine compositesworld.com A SAMPE panel headed by University of Alabama at Birmingham professor Uday Vaidya took on the topic of Thermoplastic Composites Technology, at a 2:30 p.m. session on Tuesday. Thermoplastic (TP) materials are gaining increasing attention for aerospace, automotive, energy, sporting goods, defense and emerging applications, thanks to their toughness, ability to be processed very rapidly and recyclability. The six panelists, chosen in equal numbers from industry and academia, included (in addition to Vaidya) Dr. Mark Janney, chief scientist at Materials Innovation Technologies (MIT); Shridhar Yarlagadda, assistant director of research at the University of Delaware’s Center for Composites Materials; Ed Pilpel, president of Polystrand; Mike Favaloro, president and CEO of CompositeTechs LLC; and Dr. Brent Strong, professor emeritus at Brigham Young University and head of Strong and Assoc. LLC. The session started with Strong’s overview of the thermoplastic resin space, which he compared to thermoset resins in terms of properties. He noted the differences between low-cost, commodity thermoplastics (nylon, PE, PP, etc.) which have existed for a century, and high-end advanced thermoplastics such as PEEK, PPS and PEKK, which exhibit very good solvent resistance, higher use temperatures and, with that, higher cost. Long and intertwined molecular structure gives thermoplastics their toughness and elongation, since they can move under applied load. Favaloro, who referred to TPs as “the first out-of-autoclave materials,” reviewed some of the current technologies and markets, and noted some new approaches, including Firewind developed by Fibrtec (located in Booth 1836 at the show), a method of preheating the tool to help facilitate molding of continuous fiberreinforced TPs. Ed Pilpel stressed that his company’s focus on and development of thermoplastic materials for industry came as a result of wanting to reduce waste while processing faster. His continuous fiber reinforced TP products are used in automotive, truck and aerospace applications. Yarlagadda looked critically at the positives and the negatives presented by thermoplastics. He pointed out that the very high processing temperatures required to melt advanced thermoplastics have in the past made it difficult to combine them with fibers, especially carbon, since the fiber sizing is severely compromised at those high temperatures. Without adequate sizing, the fiber/resin bond can be a problem, making it impossible to “capture the high toughness” of the material. New sizing forms are helping. He also stressed that modeling is needed whenever a complex part geometry is planned, for instance in a molded automotive part, since broadgoods will shift and fiber direction and orientation will change during molding. Very fast cycle times are nonisothermal, further complicating the picture. His wish: a fully coupled design/ analysis/process model that includes fiber orientation. Yarlagadda cautioned attendees to be careful and to consider these potential problem areas. Finally, Janney discussed the issue of recycling thermoplastic composites, particularly those containing carbon fiber. After noting that the short, discontinuous fibers that result from recycling will never match continuous carbon fiber performance, he went on to say that nevertheless there is opportunity to use recycled fibers. He discussed his company’s trademarked Co-DEP technology that commingles recycled carbon fibers with polymer fibers in a wet-laid process to produce processable mats. Innovation in Motion See a wide range of innovative solutions on display at our booth...and be sure to check out these 3M technical session presentations: Nanosilica-Modified Tooling Prepregs James Nelson Composite Erosion Protection Films Ryan Marx Nanosilica-Modified Epoxies for Filament-Wound Drive Shafts James Nelson V i si t Bo o t h u s at 26 durin 39 g CA M X ! For dates and times, see the latest presentation schedule posted at the 3M booth. Join the Winners’ Circle! Sign up at the 3M booth for your chance to win great 3M Racing NASCAR® -themed prizes! Enabling lighter, safer, quieter vehicles – constructed faster. NASCAR is a registered trademark of the National Association for Stock Car Auto Racing, Inc. www.theCAMX.org/mobile 5 THE COMPOSITES AND ADVANCED MATERIALS EXPO CAMX 2014: North American composites industry’s first jointly managed event By Sara Black CompositesWorld Magazine compositesworld.com CAMX represents an exciting and new collaboration in the North American composites industry, bringing together the conference and trade show efforts of the American Composites Manufacturers Assn. (ACMA, Arlington, Va.) and the Society for the Advancement of Material and Process Engineering (SAMPE, Covina, Calif.). We talked with representatives of each trade group to capture their thoughts on how this event meets the needs of a fast-evolving industry, and have presented the discussion in a Q&A format. Jay Merrell of Norplex-Micarta is chairman of the board of ACMA. He’s been involved in the composites industry for more than 30 years, working in technical development, sales, operations and administration. He has been involved with ACMA committees and its board for almost 10 years. Paul Wienhold, of Johns Hopkins University’s Applied Physics Laboratory (JHU/APL), is SAMPE’s immediate past president North American. He has more than 30 years’ experience in the design, development, fabrication and project management of composite structures and Vacuum bag processing aids By Mike Musselman CompositesWorld Magazine compositesworld.com Jiaxing Sunny FRP Industries Co. Ltd. (Jiaxing, China) in Booth 3980 offers North American composite processors access to its peel ply and other vacuum bagging systems materials. The ISO9001:2008certified company’s disposables for infusion processing are already in wide use, says the company, in wind energy, aerospace, marine, automotive and motorsports applications. CAMX visitors can be introduced to a number of products: • Vacuum bagging films in widths ranging to 4,000 mm/157 inches and working temperatures as high as 230°C/446°F. • Perforated release films in widths ranging to 1,600 mm/63 inches and working temperatures as high as 180°C/356°F. • Breathers in widths ranging to 4,000 mm/ 157 inches, in weights ranging from 150 to 450 g/m2, and working temperatures as high as 450°C/842°F. Additional products include flash tape, spiral winding and nylon resin tubes, connectors and valves, and sealant tapes. 6 Thursday, October 16, 2014 bonded assemblies. Show Daily: CAMX 2014 represents the first time that SAMPE and ACMA have cooperated to present a conference and trade show. What does this say about composites fabrication and manufacturing in North America? J.M.: I think the combination is great for the composites industry because it blends the higher performance materials with higher volume production capabilities. It will generate more exposure for the entire spectrum of materials, applications and processes. P.W.: The joining of ACMA and SAMPE shows that the high-performance aerospace composites and advanced materials industry seeks lower cost solutions and that the cost-efficient composites industry seeks improved performance. Show Daily: Many composites professionals are used to attending ACMA’s COMPOSITES show and conference or the SAMPE Annual Conference. What should they look for at CAMX that will make this new event of interest and benefit? J.M.: Attendees will see the best of both ACMA’s and SAMPE’s traditional shows; it is like two shows in one. P.W.: CAMX is the first very large North American conference and exhibition that fully encompasses the entire composites and advanced materials field, from reports of advanced materials development to low-cost commodity materials. Show Daily: What do you recommend for composites professionals attending CAMX who are pursuing business opportunities and relationships? J.M.: There are many opportunities to network with other visitors, not only in the educational tracks and the show floor, but also evening receptions. P.W.: All aspects of the composites and advanced materials industry are represented at the CAMX exhibition. We expect a large number of corporate leaders and decision makers in attendance. Show Daily: How might CAMX help composites professionals overcome some of the challenges facing the industry? J.M.: I think blending of the highperformance resins and reinforcements with lower-cost materials and processes is critical, satisfying the customer’s requirements as cost-effectively as possible. P.W.: In many cases new materials are available to help increase system performance, but the cost of qualification is prohibitive. Collaboration based on agreements made at CAMX between organizations can help solve this problem. Autoclaves for economical operation By Mike Musselman CompositesWorld Magazine compositesworld.com Valencia, Calif.-based ASC Process Systems is hosting three of its smaller products in Booth 2151 but also highlighting the ASC-built autoclave — the world’s largest, with a working area of 30 ft by 75 ft (9.14m by 22.86m) — that now cures fuselage sections in Charleston, S.C., for The Boeing Co.’s (Chicago, Ill.) 787 Dreamliner. The company also features its trademarked Econoclave, touted as the world’s most popular composite curing autoclave. As aerocomposites manufacturers seek ways to cut cost and increase production rates, the autoclave, that indispensable tool for ensuring proper consolidation and specified low void content in flight-critical aircraft components, has come under scrutiny because of the high capital investment and high cost of operation. ASC’s Econoclave was designed to reduce both. The system’s popularity is attributed to its comparatively low operating cost, the result, in part, of ASC’s proprietary Composite Processing Control (CPC) software and control system. ASC claims that this aerospace-grade autoclave can save the user tens of thousands of dollars per year in electricity, compressed air and nitrogen consumption, compared to conventional autoclave systems. Standard models are available in sizes that range from 1 ft to 15 ft (0.3m to 4.6m) in diameter and 2 ft to 20 ft (0.61m to 6.1m) in length. ACMA recognizes outstanding members By Jeff Sloan CompositesWorld Magazine compositesworld.com The peak event of CAMX for the members of the American Composites Manufacturers Assn. (ACMA, Arlington, Va.) will be held today at the ACMA Awards Luncheon, 12-1:30 p.m. in Valencia Ballroom B on the fourth level of the West Hall lobby in the Convention Center. ACMA will present its most prestigious awards: the 2014 Association Awards for Lifetime Achievement, Hall of Fame inductees and the ACMA Volunteer of the Year. ACE Award winners will also be formally recognized and celebrated (see story, page 1), and CAMX Technical Paper winners will also be announced. Additionally, the ACMA chairman of the board and ACMA president will share ACMA business and future plans. The ACMA Lifetime Achievement award is given to a person who has been involved in the composites industry for at least 20 years and has made a significant and lasting contribution to the industry. Significant and lasting contribution includes, but is not limited to, exemplary contribution to legislative and/or regulatory affairs of significant long-term consequence to the industry; invention of a process or product that has significant long-term importance; a very successful business career in which measurable contributions have been made to industry, government, employees or the community; leadership throughout his/her career to the industry’s trade associations where lasting contributions were made. Hall of Fame inductees have attained distinction among their peers through efforts, involvement and accomplishments in the composites industry and its associations. Criteria include contribution to legislative and/or regulatory affairs of significant long-term consequence to the industry; invention of a process or product which has commercial value to the composites or cast polymer industry; a successful business career in which notable contributions have been made to the composites industry; active, extensive participation in the industry’s trade associations with significant contributions; or academic contribution which has resulted in a noteworthy impact on the composites industry. There are currently 94 composites professionals in the ACMA Hall of Fame. The ACMA Volunteer of the Year is a member who has contributed significant volunteer time and effort to achieve positive results on behalf of the industry through service to ACMA. This can include service or leadership of a committee or can be work on a special project on behalf of the organization. Tickets are required for the ACMA Awards Luncheon and are included with Premium and Full Conference CAMX registrations. Mark your calendar for CAMX 2015 Plan on CAMX becoming a fixture on the North American composites events calendar. Indeed, CAMX 2015 is already booked for Oct. 26-29, 2015, at the Kay Bailey Hutchison Convention Center in Dallas, Texas. Like the 2014 version, it will feature four days of conferences (Oct. 26-29) overlapping three days of exhibits (Oct. 27-29). We’ll see you next year in Dallas. Advanced Material Solutions Composite and Wafer Machining IKONICS AMS employs a unique machining technology, minimizing substrate compromise and maximizing perforation variety, including non-circular perforations on complex-curved, irregular surfaces. IKONICS AMS is particularly beneficial in applications featuring challenging material, ie: Carbon Matrix Composites (CMC), Ceramic Composites, and other brittle substrates. See us at Booth #1830 IKONICS Advanced Material Solutions 4832 Grand Avenue, Duluth, MN 55807 USA direct: (218) 624-6443 | toll free: (800) 328-4261 ext.358 | web: www.ikonicsams.com | email: [email protected] An IKONICS Company ISO 9001 Certified ITAR Compliant NASDAQ Listed: IKNX www.theCAMX.org/mobile 7 THE COMPOSITES AND ADVANCED MATERIALS EXPO CAMX — Thursday on the Floor By Ginger Gardiner CompositesWorld Magazine compositesworld.com Adfors (Booth 3144), the composite reinforcements division of Saint-Gobain, presents its ESF Technology products, where carbon, glass and polymer fibers can be laid in angles from 20° to 75°, as well as 0° and 90°, and are bonded with a thermoplastic filament, not stitched. With areal weights below 100 g/m2, ESF scrims are being used in surf-, snow- and paddleboards; kayaks; canoes; and other performance sporting goods. PPG (Booth 3161) showcases its Innofiber XM for highly oriented composite applications and Innofiber CR for corrosion resistance applications. XM offers 15 percent higher modulus and CR offers higher resistance to acid corrosion vs. standard E-glass. Innegra (Booth 3957) displays a winning kayak design featuring Innegra HIC high-toughness fiber commingled with carbon. Watch for the trademark black and white flecked fabric across the exhibit floor as numerous textile suppliers are converting the fiber into interesting forms. Keyrou (Booth 4145) exhibits its Sleek Impact SI series of composites for electronics cases, including cellphones and tablets, as well as the Wood S series, where Ebony and Black Apricot are combined with Kevlar aramid fiber for a unique combination of aesthetic appeal and impact performance. Knowlton Technologies Inc. (Booth 3148) offers a wide range of nonwoven composites mixing carbon, glass, aramid and cellulosic fibers which are then saturated with phenolic resin and used as friction surfaces in heavy-duty vehicle sealed-brake systems and automotive transmissions, as well as in aviation fuel tanks and fuselage fire protection. Knowlton’s development of innovative composite webs is further augmented as it is acquired by global transportation and building/construction materials supplier Eastman Chemical Co. Conductive Composites (Booth 3248) displays its Nanostrand lightweight fibers which are nickel-coated via chemical vapor deposition to provide 3-D oriented electrical conductivity on par with metals but with low metallic loading. Ferromagnetic See Thursday – On the Floor, continued on page 9 Save the Date! CONFERENCE October 26-29, 2015 EXHIBITS October 27-29, 2015 COMBINED STRENGTH. UNSURPASSED INNOVATION. Dallas, Texas, USA Dallas Convention Center www.theCAMX.org Produced by 8 Thursday, October 16, 2014 Thursday – On the Floor, continued from page 8 and corrosion-resistant, Nanostrand is used in lightweight antennas and EMI-shielded structures. The fibers can be used in all composite processes including 3-D printing. Creative Pultrusions (Booth 3361) invites attendees to pick up its Transonite panels with composite skins and polyisocyanurate foam core which can be z-direction or truss web reinforced in widths up to 8.5 ft and also CNC machined into custom shapes. Aonix Advanced Materials (Booth 3090) announces its Ultra-I CF and Ultra-S CF materials combining carbon fiber with an imide-based (I) and sulfone-based (S) high-performance thermoplastic matrix, respectively. Used to mold thin, shaped composites with very low cycle times, the Aonix process can also use recycled materials. Lingrove (Booth 3468) exhibits its natural fiber prepregs, dry reinforcements and cores, used in combination with carbon and glass fibers to produce lightweight musical instruments, sporting goods, architectural and automotive structures with unique vibration damping and aesthetic properties. Sandvik (Booth 3768) shows its doublebelt continuous production process equipment for high-performance composite sheets, enabling both efficient lamination and compression operations for use with fiber, mat and web with thermoplastics or thermosets. Dieffenbacher (Booth 3753) exhibits its high-pressure RTM (HP-RTM) and tailored direct long fiber thermoplastic (LFT-D) equipment capabilities. Dunstone (Booth 4144) displays its Hi-Shrink Tape and Tubing which aids consolidation in oven cure processes by applying compaction pressure during cure. In resins, Bayer MaterialScience (Booth 3145) stresses collaboration in its display of polyurethane systems used in shipping pallets, modular utility poles and other composite structures. Total Cray Valley (Booth 3757) discusses its Poly bd and Krasol resins featuring hydroxyl-terminated polybutadiene to provide flexibility at low temperature, low moisture vapor transmission rate (MVTR) and adhesion to many substrates. TSE Industries (3645) highlights its EcoSpray bio-based polyurethane resins for spray layup offering low exotherm and low viscosity for wetting out complex reinforcements. ESA Comp (Booth 3661) enhances Altair Engineering’s HyperWorks computer design software, enabling predesign including efficient laminate buildup and materials optimization, and postprocessing using advanced failure criteria. Cornerstone Research Group (Booth 2355) and its subsidiaries discuss recent delivery of a 90-ft composite cantilever beam to the Dept. of Energy waste isolation plant in seven weeks. Part of this project success is No Oven, No Autoclave (NONA) 350°F epoxy resin which enabled 72 parts, totaling 1,500 ft2, to be made in three weeks, including tooling. Another spinoff, Advantic (Booth 2355), has delivered composite solutions into infrastructure applications reducing weight up to 75 percent with 6× faster installation. Managing hazards associated with thermosets By Mike Musselman CompositesWorld Magazine compositesworld.com On Wednesday at 8:00 a.m., three speakers in the CAMX Regulatory & Legislative conference track underscored proper safety procedures for those who handle and process thermoset resin systems. Brian Karlovich, a senior product safety representative at Bayer MaterialScience LLC (Pittsburgh, Pa.), spoke on safe handling of two-part polyurethanes (PUs). Noting that they are no threat to health when cured, Karlovich drew attention to hazards associated with PUs’ two basic constituents prior to processing: polymeric methylene diphenyl diisocyanate (pMDI) and Polyol. Both parts are nonflammable, but in a closed container or drum, water exposure could cause a reaction that would build pressure and burst the container. Although pMDI has an odor, the compound has extremely low volatility. The exposure limit over 8 hours is a low 5 parts per billion (ppb) with an upper limit of 220 ppb. Polyol, says Karlovich, has no listed ppb limit for 8-hour exposure. At elevated temperatures, temporary respiratory irritation can result, as can sensitization. Karlovich recommends that employers practice medical surveillance, requiring complete physicals, pulmonary testing and regular checkups for all employees. Bruce Colley, product manager for the Derakane and Hetrons brands at Ashland Performance Materials (Dublin, Ohio), discussed the issues with diluents and additives in unsaturated polyester and vinyl ester resins. Inhalation can cause dizziness, headaches or nausea, and skin contact, eye contact and ingestion should all be avoided. But the primary hazard is flammability — a concern even with fire-retardant formulations, which are flammable prior to cure. Paul Ubrich, technical service representative of Momentive Specialty Chemicals (Columbus, Ohio), offered advice on epoxies used in composites. Although they contain no solvents, skin irritation is a risk. Preventing direct worker contact is the key to avoid contact dermatitis and, potentially, sensitization. Each of the three speakers were united on a number of preventive measures, regardless of the resin system in use, such as the use of MSDS sheets, ventilation equipment and personal protection equipment (PPE), as well as no smoking. www.theCAMX.org/mobile 9 THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Mold temperature control systems Edge filling for sandwich structures Mokon (Buffalo, N.Y.), a manufacturer of heating and cooling temperature control systems located in hazardous and nonhazardous areas, provides systems for applications that require process temperatures from -20°F to 700°F (-29°C to 371°C). In Booth 1754, Mokon is displaying its line of compact water systems for temperature control for process heating requirements up to 380°F/193°C. Standard systems are available with up to 96 kW of heating capacity and motors up to 10 hp, with flow rates ranging from 10 gpm to 120 gpm. Single- and dual-zone; positive and negative pressure flow; cooling circuits; and engineered systems are also available. Also in the booth are circulating oil temperature control systems for process heating requirements up to 700°F/371°C under relatively low pressures. Oil systems are available with heating capacities up to 600 kW; flow rates of 5 gpm to 120 gpm; single-, dual- and triple-zone configurations; positive and negative pressure flows; portable or stationary designs; and cooling circuits. Mokon, Booth 1754 Positive rod displacement metering systems Material characterization testing instruments Nordson SEALANT EQUIPMENT (Plymouth, Mich.) is displaying its positive rod displacement metering system, designed to provide composite manufacturers with high-precision dispensing of adhesives and sealants, in Booth 1955. Positive rod displacement metering systems for two-component composite materials are available from 0.2 cc to 1,400 cc. Precision composite dispensing systems are fixed-ratio, from 1-1 to 10-1 and higher. Continuous flow metering systems are also available for larger volumes and continuous dispensing applications. Nordson SEALANT EQUIPMENT is also showcasing its new Dual Cartridge Dispensing System for robotic dispensing of premixed aircraft adhesives and sealants directly from cartridges. This new product is said to be ideal for robotically applying aircraft sealants in fuselage and wing environments where manual dispensing is currently performed. Nordson, Booth 1955 10 Thursday, October 16, 2014 NETZSCH Instruments North America LLC (Burlington, Mass.) is introducing four new scientific instruments for characterization of composite materials in Booth 1643. These include a differential scanning calorimeter, DSC 214 Polyma, with live demonstration; flash thermal diffusivity/conductivity analyzer, LFA 467 HyperFlash; dielectric thermoset curing monitor, DEA 288 Epsilon; and dynamic mechanical analyzer, DMA 242E Artemis. DSC 214 Polyma differential scanning calorimeter is used to characterize the heat flow behavior in composite materials both pre- and post-cure, including glass transition, melting points, heat of curing reaction and thermal kinetics/reaction rate of cure behavior from cryogenic temperatures up to 600°C/1112°F. The new DSC is designed for use in R&D and QC/QA applications and features unique software to identify unknown polymers in material mixtures. Dr. Pam Shapiro is performing live demonstrations of the DSC system at the company’s booth during CAMX. Also new is LFA 467 HyperFlash flash analyzer for characterization of thermal diffusivity, thermal conductivity and specific heat of composite materials. The instrument performs nondestructive testing on up to 16 samples from -125°C/-193°F to 500°C/932°F and measures the time needed for heat energy to transfer through a composite structure. This time-response is used to then calculate the thermal conductivity of the material. The new DEA 288 Epsilon is also featured for in-situ cure monitoring of thermoset resins used in composites. The instrument’s electrode sensors can be fed directly into composite parts that are placed in ovens, autoclaves or in molds to determine their optimum curing parameters and time of cure completion. Last, the company is displaying the new DMA 3M (St. Paul, Minn.) is featuring at its Booth 2639, among other things, a case history involving an edge-filling application on a sandwich structure. The case history highlights a time trial between a two-part, hand-mixed product and 3M’s Scotch-Weld Structural Void Filling Compound EC-3550 B/A FST. 3M says completion time using its compound was reduced by 75 percent and that material waste was significantly reduced. The Scotch-Weld compound is supplied as a two-part, extrudable filler in a cartridge, which requires no weighing or mixing. 3M, Booth 2639 M 3 B a p a ( c s y 242E Artemis dynamic mechanical analyzer, which is used to accurately measure viscoelastic properties, glass transition temperature and curing behaviors of heavily filled composite materials from cryogenic temperatures up to 600°C/1112°F. The instrument features a variety of sample fixtures including threepoint bending, single- and dual-cantilever as well as shearing and compression. NETZSCH Instruments North America LLC, Booth 1643 w 2 Product News at CAMX 2014 Tension control technologies Web tension control specialist Montalvo (Gorham, Maine) unveils new tension control concepts and technology as both an exhibitor in Booth 3357 and as a conference program presenter. The company is featuring its multitow tensioning nip stand, which creates a drop-in solution for manufacturers who use multiple creels of material. This solution is said to offer a tensioning system that integrates well into existing applications, allowing tension to be precisely controlled on each of the individual pieces of material. Montalvo is also demonstrating how tension control equipment can be incorporated into hand layup, filament winding, pultrusion and prepreg applications. On the conference side, Montalvo is presenting “Tension Control in Spread tow reinforcement solutions Composites Manufacturing to Achieve Automated Processing and Reduced Waste,” Thursday, Oct. 16, 10 a.m. in W224 C. Montalvo, Booth 3357 Spread tow reinforcements specialist Oxeon AB (Boras, Sweden) is featuring in Booth 3345 its line of TeXtreme fiber products. Oxeon’s spread tow reinforcements have been applied to products and structures in the aerospace, Formula 1, marine, industrial and sporting goods markets. Oxeon says the material is often credited with helping fabricators achieve an additional 20 to 30 percent weight savings over traditional carbon fiber reinforcements. In the conference, Mark Shioleno, sales manager aerospace – North America, delivers a presentation Thursday, Oct. 16, 10:30 a.m., titled “Experimental Failure Investigation of Spread Tow Fabrics” in W224 F. Oxeon AB, Booth 3345 Resin mixing technology In Booth 2960, THINKY USA Corp. (Laguna Hills, Calif.) is introducing the THINKY ARE-310, a new mixing technology, codeveloped with Tokyo University of Science, Department of Applied Chemistry, for carbon nanotube (CNT) dispersion in a resin matrix. The THINKY ARE-310 uses centrifugal force and can disperse materials softly without any damage to the resin or CNTs. The THINKY ARE-310 mixer reportedly can disperse CNTs uniformly without shearing, thereby enhancing resin conductivity. THINKY USA Corp., Booth 2960 MEET THE MARK ONE™: THE WORLD’S FIRST COMPOSITE 3D PRINTER. 3D PRINT CARBON FIBER. Brilliant ideas need brilliant materials. The Mark One™ uses a patent pending Composite Filament Fabrication (CFF™) process to 3D print continuous strand carbon fiber, Kevlar®, and fiberglass. Utilizing the CFF™ print head and one FFF (Fused Filament Fabrication) print head, the Mark One can create astonishingly robust parts by reinforcing MarkForged’s special blend of nylon with continuous fiber filaments. Now you can 3D print functional parts with a higher strength-toweight ratio than 6061-T6 aluminum – at your desk. VISIT US AT BOOTH 1533 Kevlar® is a registered trademark of DuPont E.I. du Pont de Nemours and Company or its affiliates. 20x stiffer than ABS. 5x stronger than ABS. Carbon Fiber • Kevlar® • Fiberglass Nylon • PLA LEARN MORE AT MARKFORGED.COM 11 www.theCAMX.org/mobile THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Composites design analysis software In Booth 3072, Collier Research Corp. (Hampton, Va.) is holding public and private demonstrations of HyperSizer, its software used to lightweight the heat shield of NASA’s Orion Multi-Purpose Crew Vehicle. NASA’s Orion team used information gathered from HyperSizer analyses to inform discussions that led to a 1,100-lb/500-kg reduction of the final weight of the baseline design. The uncrewed test flight of the vehicle, Exploration Flight Test-1, is currently slated for December 2014. The final HyperSizer-designed heat shield will be used on later, manned flights. HyperSizer, the first software commercialized out of NASA, provides stress analysis and sizing optimization for reducing the weight of aircraft, wind turbine blades and other structures in addition to space vehicles, whether designed with composite or metallic materials. A typical HyperSizer analysis is said to produce weight savings of between 25 and 40 percent. James Ainsworth, aerospace stress engineer at Collier Research, will present “Automated Design and Analysis of Alternative Concepts for the Orion Heat Shield Carrier Structure,” Thursday, Oct. 16, 11:30 a.m. in W224 B. Collier Research Corp., Booth 3072 Automatic and manual cutting equipment Eastman Machine Co. (Buffalo, N.Y.) is introducing a new automatic cutting system model and holding daily cutting demonstrations on several composites-configured manual cutting machines in Booth 2059. The Eagle S125 Static Table Cutting System is a solution for R&D or production cutting of nested pattern pieces from dry and prepreg composite materials in sheet or rolled form. The S125 is engineered with an industrial design for rigorous use, including an advanced regulator for precise tool pressure control; built-in surge protection; heavy-duty cable connectors; and a heavygauge steel construction with scratch-resistant powder-coated finish. The operating computer and control cabinet are housed in independent enclosures that are sealed to provide dust and water protection in harsh or high-particulate environments. Additionally, cabling connectors, servomotors and display components meet recognized international protection ratings requirements. The Eagle S125 may be configured in various widths and lengths to match customer requirements. A range of tool head accessory options for marking and printing, plus various cutting surfaces, are available to optimize cutting results for any given material. Eastman’s line of manually operated cutting machines is also available for demonstrations, configured for composites applications. Model features are developed in response to new and high-tech materials’ cutting requirements. Eastman says its manual cutting machines feature many of the same benefits as automatic cutting, at a much lower investment. Eastman Machine Co., Booth 2059 Composites design, tooling and manufacturing services Matrix Composites (Rockledge, Fla.) emphasizes its range of high-performance composite manufacturing services including design, development, tooling, testing and integration. Markets served include aerospace, defense and commercial/general aviation. Visitors to Matrix Composites’ Booth 3060 will find examples of the company’s work, including spacers, radomes and vents. “A growing number of companies are realizing the significant benefits of composite components,” says Jeffrey Sharbaugh, Matrix Composites’ business development manager. “Over twenty years of lessons learned is a true differentiator for Matrix and our latest 12 Thursday, October 16, 2014 advancements in closed molding could really open up new doors for these companies.” Matrix Composites, Booth 3060 Composites manufacturing automation Robotmaster (St. Laurent, Quebec, Canada) is unveiling tools designed for the manufacture of composite parts using robots. The capabilities of Robotmaster are being demonstrated live in Booth 1847, with a KUKA robot trimming a carbon fiber part. In addition, Robotmaster showcases: • Automated fixture creation with one-click design/creation of trimming jigs; • Configurable universal holding fixtures (UHF), a single programmable solution to replace several mounting jigs; • Comprehensive support for simple to complex drilling and riveting; • Automated and flexible trimming using intelligent analysis tools; • Introduction of fiber layup programming; and • Enhanced simulation support for complex manufacturing applications. UHF programming is being demonstrated live in the Robotmaster booth. The company is also debuting new programming methods designed to enhance process control for inspection and nondestructive testing (NDT). Robotmaster, Booth 1847 Fiber measurement systems Dia-Stron (Broomall, Pa.) is featuring in Booth 3956 its integrated measurement systems for single fibers and filaments. The technology uses a combined laser diffraction and highresolution extensometer measurement system (LDS/LEX) that combines measurement integration, precision and automation. Dia-Stron notes that diameter measurement is an essential parameter in mechanical testing of fibers, and the Dia-Stron system incorporates a high-resolution laser diffraction system with the linear extensometer force measurement unit, collecting dimensional and mechanical data in a single operation. The integrated measurement system is then combined with Dia-Stron’s automated sample loading module that transports the samples from the loading cassettes to the measurement module. Dia-Stron also supplies handling devices and loading cassettes to improve productivity and reduce sample loss, as well as modules for fiber bending, fatigue and torsion. Dia-Stron, Booth 3956 Product News at CAMX 2014 Rigid, unfaced polyiso/ urethane foam core Elliott Co. of Indianapolis Inc. (Indianapolis, Ind.) is featuring its line of rigid, unfaced polyiso/ urethane foam core materials in Booth 2052. Available in blocks, sheets and custom shapes, ELFOAM products offer a broad range of insulating, fire-resistant and structural physical properties. Depending on the application, ELFOAM’s significant weight savings, strong chemical resistance and operating temperature range of ±300°F makes it suitable for use in panels, inserts, slopes, tanks, doors and equipment. Also available are new fabrication capabilities to complement the company’s established sheeting, scoring, perforating and profiling capabilities. Elliott Co. , Booth 2052 Granite effect coatings, polymers The R.J. Marshall Co. (Southfield, Mich.) features three product categories in Booth 2252: Spraylite lightweight filler system, Spray Granite Advantage granite effect coating, and flameand smoke-retardant additives. Spraylite is a sprayable, lightweight filler system composed of resin-extending lightweight polymeric microspheres. These microspheres can reduce cost, reduce VOC emissions and help improve processing. The microspheres are resilient and reportedly will not break down during mixing. They also are flexible and will elongate while being sprayed though a mix tip, instantly reforming to their spherical form afterward. The Spray Granite Advantage (SGA) line is an economical granite effect coating filler system designed to be mixed into a clear gel coat and sprayed behind a clear gel coat or against the mold as a primary wear surface. SGA color granules are made from a UV-stable thermoset polyester resin and alumina trihydrate (ATH) fillers. Featuring more than 50 unique colors and textures, SGA can be used as sprayup coating in composite products or as granite effect filler in sheet molding and bulk molding compounding (SMC/BMC). The flame- and smoke-retardant additive products include a range of ATH fillers. The Maxfil line is designed for maximum filler loadings, extremely low resin viscosities, increased flame retardance and decreased formulation cost. R.J. Marshall Co., Booth 2252 Compression molding machines, plasticators LMG (De Pere, Wis.) features its array of compression molding presses, plasticators for preparing long fiber-reinforced thermoplastics for compression molding, and resin transfer molding (RTM) presses in Booth 3868. LMG has been building hydraulic presses of 5 tons to 3,300 tons for more than 75 years. Press styles include standard compression, transfer presses, shuttle presses, vacuum presses, horizontal presses and multiple opening presses for thermoplastic and thermoset applications. Hydraulic systems range from very basic to servocontrolled high-speed systems with multiple profile process control and leveling. LMG also offers turnkey systems that include mold, infrared oven, automation and auxiliary process equipment. LMG, Booth 3868 EDUCATION HUB Your 24/7 Resource for Composites Education The new ACMA Education Hub helps you: • Enroll in the CCT program and take your exam online • Recertify your CCT credentials • View past webinars and enroll in upcoming live webinar events • Purchase important technical resources, including ANSI Codes of Standard ACMAEducationHub.org Baltimore Convention Center Baltimore, Maryland, USA May 18-21, 2015: Conference | May 19-20, 2015: Exhibits SAMPE is now accepting abstracts for SAMPE Baltimore 2015 ► Abstracts are due by October 24, 2014. ► If your abstract is accepted, Technical Papers are due no later than January 16, 2015. SUBMIT YOUR ABSTRACT TODAY www.sampebaltimore.org www.theCAMX.org/mobile 13 THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Thermoset compounding materials The Composites Group (TCG, Highland Heights, Ohio) and its three business units, Quantum Composites, Premix and Hadlock Plastics, collectively feature five new thermoset compounding materials in Booth 3369 and two technical presentations at CAMX 2014. New are PremierUV and PremierLT, two high-performance product families of ultraviolet-resistant and lightweight thermoset sheet molding compounds (SMC), respectively. The PremierUV line is comprised of PremierUV VSH-25S and PremierUV VLH-25S, for electrical and outdoor applications, including electrical enclosures, light housings and warning tiles. Both are fiberglass-reinforced compounds with nonhalogen, flame-retardant technology that deliver good color retention as well as resistance to chalking and glass bloom. The PremierLT family of lightweight, low-density materials is designed to meet market needs for structural and semistructural applications. PremierLT L701S boasts a specific gravity of 1.2 along with good moldability. It is pigmentable and offers low shrink. PremierLT L702S offers good strength and moldability with a specific gravity of 1.5. It is said to deliver excellent flexural strength and toughness and accepts automotive primers and powder in-mold coatings. Also new is Quantum Composites’ first hybrid carbon fiber material, AMC-8590-12CFH, an Advanced Molding Compound that offers the performance benefits of carbon fiber at a cost similar to high-performance fiberglass. It is said to be easily moldable, delivering parts that are high-strength, low-density and resistant to fatigue, suitable for applications in the automotive, heavy truck, medical, sporting goods and industrial markets. The Composites Group, Booth 3369 InChem says recent application research has found that phenoxy resins can be highly effective when used in composite prepregs, carbon nanotubes and other advanced composite applications. Phenoxy resins are distinguished by three main characteristics: • Clear: haze values typically <5 • Tough: tensile strength 9,000 to 9,500 psi • Flexible: tensile elongation 50 to 100 percent Phenoxy resins are available as pellets, waterborne solutions, solvent solutions and film. Company officials note that because of its long hydroxyl backbone, phenoxy crosslinks with a variety of chemicals, resulting in a new hybrid product that has the characteristics of both. InChem Corp., Booth 3446 Phenoxy resins InChem Corp. (Rock Hill, S.C.) emphasizes in its Booth 3446 new applications for its line of phenoxy resins. Phenoxy resins are tough, clear and flexible thermoplastic chemicals with high cohesive strength and good impact resistance, designed to enhance the performance of coatings, inks, composites, adhesives, carbon fibers and other products. COMBINED STRENGTH. UNSURPASSED INNOVATION. October 13-16, 2014: Conference / October 14-16, 2014: Exhibits Elite Sponsors Supporter Sponsors Contributor Sponsors 14 Thursday, October 16, 2014 LOOK! It’s Vacuum Infusion. It’s Reusable Bag Molding. It’s Light RTM. It’s Prepreg. IT’S ALL THAT AND MORE! THE NEXT GENERATION LEAN MEAN CLOSED MOLD MACHINE 5 demos, 5 parts, 5 markets, 5 times the value! Plus a new technology and the latest high performance materials! IT’S SUPER DEMO 5 TIMES MORE POWERFUL! see it LIVE at Booth #2772 during CAMX 2014 in Orlando, October 14-16 Brought to you by Composites One and the Closed Mold Alliance along with our industry partners The most important thing we build is trust Excellence in Advanced Composite Production and Design Solutions Cobham is recognised as an industry leader for the design, development and manufacture of a wide range of composite structures. Cobham’s composite business units cover all composite processes including Resin Transfer Molding (RTM), Compression Molding, Hand Lay-up / Autoclave Cure, Advanced Bladder Molding and Filament Winding. Cobham’s award-winning composite products include aircraft engine components, aircraft and spacecraft structures, missile and munitions assemblies, pressure vessels, flywheel rims and radomes. Advanced Composite Solutions Ladder Brackets Composite Fan Blades Acoustic Panels Infill Panels Exhaust Flaps Spinner and Cap Terminal/Speed Probe Blocks Cobham Composite Products fabricates complex, hightolerance composite parts and assemblies including hightemperature engine components used on both military and commercial aircraft. Our 72,000 sq-ft facility located in San Diego, CA houses state-of-the-art compression molding presses that are automated and we utilize mechanized layup processes that are robust and repeatable to guarantee part to part consistency. Strategic Company Focus • High Temperature Aircraft Engine Components • Aircraft Engine Components and Structures Stator Vanes Ice Impact Panels Composite Fan Blades Advanced Design Solutions With core capabilities in energy storage and control, filament winding and metal to composites bonding, Cobham Life Support, in Westminster, MD produces innovative composite structures including the world’s first demisable spacecraft propellant tank, pressure vessels and flywheel rims all while meeting the most demanding weight, strength and safety requirements. Strategic Company Focus • • • • • Energy Storage Ultra-High Pressure Cylinders Aircraft Emergency Inflation and Oxygen Systems Spacecraft Components Military Rotorcraft Structures For sales inquiries or more information, please contact: Cobham Composite Products - San Diego, CA, USA T: 001 (858) 824 8958 Cobham Life Support - Westminster, MD, USA T: 001 (410) 871 9966, ext106 Visit Cobham at CAMX 2014 - Booth# 4453 www.cobham.com

© Copyright 2026