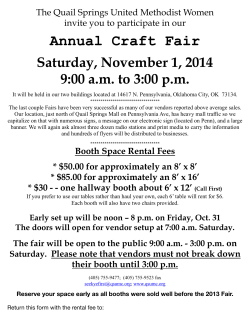

CAMX Awards given — keynote speaker inspires WEDNESDAY, OCTOBER 15, 2014 On-the-Floor Highlights:

WEDNESDAY, OCTOBER 15, 2014 IN ASSOCIATION WITH Orlando, Florida | Orange County Convention Center On-the-Floor Highlights: A review of some of the material and equipment technologies you’ll find on the show floor. PG 9 Monomer-Free Sheet Molding Compound: Efforts to develop a monomer-free SMC are starting to bear fruit. PG 6 CAMX 2014 FAQ: The past, present and future of CAMX and cooperation between ACMA and SAMPE. PG 8 NIST and Composites Acceptability: www.theCAMX.org/mobile CAMX Awards given — keynote speaker inspires By Sara Black CompositesWorld Magazine compositesworld.com CAMX attendees gathered in the fourth-floor Valencia ballroom on Tuesday morning for the General Session and keynote address, sponsored by Owens Corning. Jay Merrell, ACMA’s chairman of the board, and Ted Lynch, SAMPE’s North American president, offered their perspectives on the development of CAMX 2014. Lynch noted that “solid, strong feedback” from SAMPE members helped alleviate nervousness about the combined event, and that he is “proud” of the CAMX show. Merrell noted that the new combined event brings the industry together. Merrell and Lynch acknowledged the efforts of the CAMX Steering Committee, headed by Marcy Offner of Composites One for ACMA, and by Tom Haulik of Hexcel Corp. for the SAMPE side. Offner took the podium to welcome showgoers and describe the Steering Committee’s efforts to deliver a See Keynote, continued on page 3 Composites are earning their way into more applications, but there’s still work to be done. PG 7 Cast Polymers Luncheon Preview: The International Cast Polymers Alliance hosts its annual awards luncheon today. PG 5 Kevin Mickey, president, of Scaled Composites, said of the 2004 X-Prize, which Scaled Composites won, “Do not spend $30 million to win $10 million.” Demos and Schedules: On-the-floor demonstrations and shuttle bus schedules. PG 4 EVENTS NOT TO MISS • Exhibit Hall Open TIME: 9:30 a.m. - 5:00 pm • Job Board TIME: 9:30 a.m. - 5:00 pm Outside Room W224 • Poster Session TIME: 10:00 a.m. - 11:30 a.m. Outside Room W221 • Market Segments Reception TIME: 5:00 p.m. - 6:00 p.m. W414 - 4th Level • Aerospace • Automotive/Transportation • Building/Construction/Architecture • Energy • International • Pultrusion/Corrosion NASA-Boeing, Composite Panel Systems win CAMX Awards By Jeff Sloan CompositesWorld Magazine compositesworld.com Foundation Walls, submitted by Composite Panel Systems LLC. NASA worked with Boeing to design, fabricate The inaugural CAMX 2014 also ushers into the composites industry a new awards program, called CAMX Awards. Twelve finalists competed for two CAMX Awards, one to recognize collaboration and teamwork in a composite application, and the other to recognize innovation that promises to provide substantial market impact. On Tuesday morning during the CAMX General Session, Ashland announced the winners of the 2014 CAMX Awards. The Combined Strength Award was given to the NASA-Boeing Composite Cryotank Technologies & Demonstration Team, submitted by NASA Glenn Research. The Unsurpassed Innovation Award was given to the Epitome Quality See CAMX Awards, continued on page 3 The NASA-Boeing composite cyrotank is one of the two CAMX Awards winners. LOOK! It’s Vacuum Infusion. It’s Reusable Bag Molding. It’s Light RTM. It’s Prepreg. IT’S ALL THAT AND MORE! THE NEXT GENERATION LEAN MEAN CLOSED MOLD MACHINE 5 demos, 5 parts, 5 markets, 5 times the value! Plus a new technology and the latest high performance materials! IT’S SUPER DEMO 5 TIMES MORE POWERFUL! see it LIVE at Booth #2772 during CAMX 2014 in Orlando, October 14-16 Brought to you by Composites One and the Closed Mold Alliance along with our industry partners CAMX Awards, continued from page 1 and test an all-composite cryogenic fuel tank for space launch vehicles. The tank achieved a 30 percent weight savings and 25 percent cost savings, allowing insertion of higher mass payloads to low-Earth orbit and beyond. At the current space launch system configuration of 8.4m diameter, the composite cryotank could warrant as much as 1,400 kg/3,806 lb of added payload. Receiving the Combined Strength Award was John Vickers, NASA program manager for the Composite Cryotank Technologies & Demonstration Team. “A lot of people worked very hard between government The Epitome Quality foundation walls replace traditional concrete in home construction. Keynote, continued from page 1 combined show that will “inspire” the industry. She then introduced Andrew Beer of Ashland, the sponsor of the new CAMX Awards program. Beer highlighted the 12 entries for the CAMX Awards program, which took its cue from the CAMX motto: “Combined IN ASSOCIATION WITH Orlando, Florida County Center Orlando, Florida| Orange | Orange CountyConvention Con- www.theCAMX.org/mobile www.theCAMX.org/mobile SHOWDAILY STAFF CONTRIBUTORS CompositesWorld Magazine Jeff Sloan, Editor-In-Chief Mike Musselman, Managing Editor Sara Black, Technical Editor Ginger Gardiner, Senior Editor Rick Kline Jr., Group Publisher Ryan Delahanty, Publisher Kim Hoodin, Marketing Director Barb Businger, District Manager Rick Brandt, District Manager Eddie Kania, European Sales Manager SHOWDAILY PRODUCTION Rhonda Weaver, Production Manager Stephanie Monsanty, Editor Jeff Norgord, Art Director/Photographer Becky Helton, Advertising Manager The CAMX ShowDaily is published by Gardner Business Media, Inc. 6915 Valley Ave., Cincinnati, OH 45244 © and industry and Boeing and NASA to make this project work,” he told the crowd of more than 1,500 who attended the CAMX General Session and Keynote Tuesday morning. He noted that the tank went a long way toward proving composite capabilities in space launch applications. “We threw a lot at these tanks during testing, and they stood up.” Receiving the Unsurpassed Innovation Award was Glenn Schiffmann, managing member of Composite Panel Systems LLC (Eagle River, Wis.). He told the audience that it was two years ago, at the National Homebuilders Show here in Orlando, that he first hatched the idea of a composite sandwich panel system designed to replace traditional concrete in residential home foundations. Working with the close support of resin manufacturer Ashland, Schiffmann says his panel system provides easy and fast installation which can be performed by typical work crew, without the time and effort required to pour a concrete foundation. Further, it provides R-16.5 insulation value, integrated stud cavities for mechanicals and inherent damp-proofing. Schiffmann says reception in the building and construction industry to the Epitome Quality Foundation Walls system has been positive so far. He’s working with Ashland and other suppliers to increase manufacturing efficiencies Strength, Unsurpassed Innovation.” The flagship CAMX Award recognizes innovations that have the potential to significantly impact composites and advanced materials in the marketplace, with two awards given: one that represents a combination of strong technologies, and the second for game-changing innovation. The dozen award entries, said Beer, reflected the depth and breadth of the industry, with each having the “potential to shift market expectations.” The winners were the NASABoeing Composite Cryotank Technologies and Demonstration (CCTD) Team for the Combined Strength Award, and Epitome Quality Foundation Walls from Composite Panel Systems LLC for the Unsurpassed Innovation Award. The winners and the other award candidates can be viewed in the Awards Pavilion in the Exhibit Hall. (See story on front page.) The keynote speaker, Scaled Composites’ president Kevin Mickey, was introduced by Kim Howard of Owens Corning, who emphasized the importance of innovation, risk-taking and a collaborative working environment that is represented by Scaled Composites’ success. Mickey, an engaging speaker who referred to CAMX attendees as the “world’s brightest people,” reviewed the many ground-breaking milestones that Scaled Composites had accomplished Glenn Schiffmann, managing member of Composite Panel Systems, receives the Unsurpassed Innovation Award. and drive down the cost further and make it cost-competitive with concrete. That’s within reach, he believes. The winners of the other awards competition at CAMX, ACMA’s Awards in Composites Excellence (ACE), will be announced on Thursday at the ACMA Awards Luncheon, 12-1:30 p.m. in the Valencia Ballroom. All of the award entrants, both CAMX Awards and ACE, can be seen in the Exhibit Hall at the Awards Pavilion. since its start in 1982. One of those was the winning, in 2004, of the Ansari X-Prize of $10 million for development of a reusable rocket that could take three persons to space and return safely to earth, with funding from billionaire Paul Allen. Mickey stressed that his company builds “fast” with out-of-autoclave (OOA) technology and eschews “black aluminum.” The company’s latest venture, also funded by Allen, is the development of the Stratolaunch aircraft, an enormous plane with a 385-ft wingspan that will carry and launch a rocket capable of carrying 13,500-lb payloads to low-Earth orbit. The first flight of the Stratolaunch behemoth is slated for 2016. Mickey inspired the audience with his company’s philosophy of finding programs, like Stratolaunch, that excite his workers and make for a fun working environment. He stressed that risk-taking is important: “If you take chances, you might fail, but if you don’t take chances, you’ll never make any progress. Don’t be afraid of taking educated, calculated risks!” The success of Scaled Composites shows that being bold and taking risks, while celebrating results and learning from failures, is a winning combination. Concluded Mickey, “The process shouldn’t be the product — stop talking and start doing.” 2014 by Gardner Business Media, Inc. www.theCAMX.org/mobile 3 THE COMPOSITES AND ADVANCED MATERIALS EXPO CAMX on-floor demonstrations There is no shortage of actual manufacturing taking place at CAMX, some of it designed to highlight capability, some of it to educate composite professionals on manufacturing processing methods. Whatever your level of interest, there are several manufacturing demonstration options on the show floor. Below is a list of exhibitors that have reported they are offering demonstrations: • A&P Technology, Booth 2447: Fiber reinforcement and braided products • Composites One, Booth 2570: Closed molding processes • Entec Composite Machines, Booth 3561: High-speed filament winding • MarkForged, Booth 1533: Continuous fiber additive manufacturing • NETZSCH Instruments, Booth 1643: Material analysis instruments • RocTool, Booth 4365: High-speed injection, heating, cooling • Sandvik Process Systems, Booth 3768: Continuous process systems • SWORL, Booth 3261: Reusable vacuum membranes CAMX shuttle bus schedule The Convention Center shuttle bus stops are located in the main bus drop-off area between the Exhibit Hall C Lobby area and Conference Program Rooms W224. If you require an ADA shuttle bus or would like additional information, call 310-466-4699. (Call at least 30 minutes prior to desired pickup time if an ADA bus is required.) Hotel Route BUS ROUTE HOTEL HOTEL SHUTTLE BOARDING LOCATION Avanti Resort 1 Curbside, International Dr. Courtyard Orlando International Drive 1 Curbside, Austrian Ct. Embassy Suites Orlando — International Drive South 1 I-Ride Trolley Stop 22, International Dr. Rosen Inn Pointe Orlando 1 Curbside, International Dr. Hampton Inn Orlando 2 Walk to Springhill Suites, curbside, Universal Blvd. Homewood Suites by Hilton Orlando 2 Walk to Springhill Suites, curbside, Universal Blvd. Hyatt Place Orlando/Convention Center 2 Walk to Springhill Suites, curbside, Universal Blvd. Residence Inn Orlando Convention Center 2 Walk to Springhill Suites, curbside, Universal Blvd. Springhill Suites Orlando Convention Center 2 Curbside, Universal Blvd. DoubleTree 3 Outside of main lobby Hours of Shuttle Bus Service* Tuesday, Oct. 14 7:00 a.m.-7:00 p.m. Every 10-15 minutes Wednesday, Oct. 15 7:00 a.m.-10:00 a.m. Every 10-15 minutes 10:00 a.m.-3:00 p.m. Every 30 minutes 3:00 p.m.-7:00 p.m. Every 10-15 minutes 7:00 a.m.-2:00 p.m. Every 10-15 minutes 2:00 p.m.-6:00 p.m. Every 30 minutes Thursday, Oct. 16 *Shuttle departs Convention Center on the hour and half hour. Schedule may vary due to traffic and weather conditions. Last bus leaves from hotel 30 minutes prior to end time with no return service. 4 Wednesday, October 15, 2014 University Pavilion helps students integrate with composite professionals By Sara Black CompositesWorld Magazine compositesworld.com CAMX 2014 welcomes students and learning institutions to the event, and is providing several different ways to participate. One of these is the University Pavilion, an area of the exhibit hall dedicated exclusively to colleges and universities. The Pavilion is located in the back of the exhibit hall, near the end of the 1600 aisle, and adjacent to the CAMX Lounge seating area. Seifert and Skinner & Assoc. (Booth 1583) and Nippon Graphite Fiber (Booth 1782) are located adjacent to the Pavilion. Booths have been reserved by: University of North Carolina Charlotte – School of Architecture; International Yacht Restoration School (IYRS) School of Technology and Trades; Winona State University; North Dakota State University, Mechanical Engineering Dept.; University of South Carolina’s McNAIR Center for Aerospace Innovation; Auburn University; University of Massachusetts Lowell; University of Mississippi; Composites Washington (a consortium of 12 colleges in the Seattle, Wash., area); Florida State University High-Performance Institute; University of Central Florida; University of Alabama at Birmingham; and the Advanced Structures and Composites Center of the University of Maine. Each of these schools, groups of schools or centers has a focus on composites and advanced materials manufacturing as a concentration area, and is interested in connecting with potential students and graduate researchers. The gathering of so many prestigious institutions will give students and educators a chance to share research, obtain advice on projects and connect with people who inspire them — and who can help later in their careers. For other education resources and information, watch for the student Poster Session Competition as well as papers and presentations developed by students. Cast polymers membership awards luncheon today By Jeff Sloan CompositesWorld Magazine compositesworld.com The International Cast Polymers Alliance (ICPA, Arlington, Va.) is hosting its General Session and Awards Luncheon today, 12-3 p.m. in room W311 D in the Convention Center. In addition to lunch, the program features motivational speaker and author Glenn Carver (Stand in the Heat), who has inspired thousands of entrepreneurs, business owners, sale professionals and associations in North and South America. The book is a survival guide based on the experiences of people who have learned to overcome the pressures of today — including 15 legendary entrepreneurs who triumphed over difficult situations. ICPA members will also celebrate the accomplishments of specific individuals and companies that have produced outstanding work in the last year. A special presentation will honor the best member installations from the past year, and awards will be given for Manufacturer of the Year and Supplier of the Year. Additionally, ICPA will celebrate its heritage with the presentation of the ICPA Excellence in Leadership award. This recognition is given to individuals who have set the standard for succeeding in the cast polymer industry by supporting the association for many years; providing innovation, creativity and leadership by example; overcoming obstacles; and improving the industry for all. Innovation in Motion See a wide range of innovative solutions on display at our booth...and be sure to check out these 3M technical session presentations: Nanosilica-Modified Tooling Prepregs James Nelson Composite Erosion Protection Films Ryan Marx Nanosilica-Modified Epoxies for Filament-Wound Drive Shafts James Nelson V i si t Bo o t h u s at 26 durin 39 g CA M X ! For dates and times, see the latest presentation schedule posted at the 3M booth. Join the Winners’ Circle! Sign up at the 3M booth for your chance to win great 3M Racing NASCAR® -themed prizes! Enabling lighter, safer, quieter vehicles – constructed faster. NASCAR is a registered trademark of the National Association for Stock Car Auto Racing, Inc. www.theCAMX.org/mobile 5 THE COMPOSITES AND ADVANCED MATERIALS EXPO Research: Monomer-free sheet molding compound By Mike Musselman CompositesWorld Magazine compositesworld.com Sheet molding compound (SMC) has had a long but not always happy history in the automotive industry. Championed as a lightweight replacement for steel semistructural members and Class A exterior body parts, SMC hit hard times in the early 2000s when the baking processes used to cure automotive paint caused SMC formulations to outgas through microcracks, causing eruptions in the paint finish that automakers dubbed “paint pops.” A flurry of research projects tackled the issue and by 2004, paint-pop-free formulations were on the market. Today, SMC faces a second challenge: The U.S. Health and Human Services Department’s designation of styrene as a suspected carcinogen. SMC variously uses four reactive diluents: Styrene is the most common, but vinyl toluene, divinyl benzene and acrylates have all been used recently as styrene replacements. But the potential for regulatory difficulties with reactive diluents as a class has prompted efforts to develop reactive diluent-free resins, particularly for SMCs. CAMX 2014 opens for business The inaugural CAMX 2014 registration hall Tuesday morning ahead of the exhibit hall opening. With more than 550 exhibitors, this will be North America’s largest composites trade show. Kurt Butler, polymer engineer — R&D in the Composite Group at Premix (North Kingsville, Ohio) spoke on the subject at 8:30 a.m. Tuesday morning. He noted that there are two hurdles to development of SMCs without reactive diluents. The first is thickening of the SMC’s resin paste. The second is shrinkage control to ensure accurate finished part dimensions. A reactive diluent has been crucial to both in the past. A commercially available magnesium oxide, in a 30 to 40 percent dispersion, produced acceptable thickening, and Butler’s team also tested proprietary formulations that improve performance. After the thickening hurdle was surmounted, the task was to develop reactive-diluent-free shrinkage-control agents. A number of possibilities were tried, and Butler reports that his team has actually produced SMCs that duplicate the performance of current SMCs. In glass-reinforced formulations — ATH-filled and calcium carbonate-filled — flexural strength and modulus come close to the “control” SMC. Here, Butler considers the combination of shrinkage control and thickening “promising.” Indeed, test data show some formulations are superior in properties. In carbon fiber-reinforced SMCs, those containing proprietary thickeners and those with magnesium oxide both fell a bit short in flexural strength and tensile strength, but some showed superior tensile modulus, with comparable flexural modulus. Butler concluded by saying that reactive diluent-free resin systems can be thickened successfully for SMC compounding and, although study must continue, it is now clear that both ATH and calcium carbonate can used as fillers, with no wetting issues. Although temperature has to be elevated to accomplish thickening, standard peroxides are still used to catalyze the resins and the SMC compounding process is otherwise unchanged. Butler believes that, over time, the properties shortfalls in the carbon fiber formulations will be overcome. This evening’s networking opportunity focuses on end markets By Sara Black CompositesWorld Magazine compositesworld.com CAMX 2014 offers attendees unparalleled opportunities for networking and making valuable connections. One not-to-bemissed event is the Market Segments Reception sponsored by Composites One. The reception will be held Wednesday afternoon at the conclusion of the education and technical sessions, 5-6 p.m. in Room W414. This general networking opportunity is 6 Wednesday, October 15, 2014 designed to allow for discussion of relevant issues within specific market areas of interest. ACMA’s communications coordinator Mary Beck says that the market segments will include aerospace, automotive/transportation, building/construction/architecture, energy applications, pultrusion/corrosion and international. The event promises to be a lively and enjoyable venue to enjoy food and drink as well as conversation with market segment experts in attendance. Sponsor Composites One is a family- owned distributor with 60 years of experience in supplying composites materials to all of these market segments. The company’s network of 32 local distribution centers is dedicated to improving the composites industry with more than 30,000 products as well as technical assistance in processing methods. Be sure to check out the Lean Mean Closed Mold Machine Super Demo area in the exhibit hall (Booth 2772) to see Composites One and partner firms offer instruction and tips for closed molding technology. NIST session outlines CAIIAC road map By Sara Black CompositesWorld Magazine compositesworld.com One of the first technical sessions on Tuesday was a detailed look at a new consortium under development, with the moniker CAIIAC, or “kayak,” which stands for Consortium for Accelerated Innovation and Insertion of Advanced Composites. Presenters included Chuck Zhang and Ben Wang of the Georgia Institute of Technology; Les Kramer of Advanced Materials Professional Services LLC; and Charlie Browning of the University of Dayton. Funded by a National Institute of Standards and Technology (NIST) grant, CAIIAC aims to develop a consortium involving the entire value chain for accelerating the acceptance and use of advanced composites in multiple markets. Zhang outlined the “grand technical challenges” that composites face, with a list developed after polling key industry leaders: 1) the need for scalable and reproducible out-of-autoclave (OOA) processes on affordable tooling; 2) structural health monitoring (SHM) to monitor a part’s performance over its lifecycle; 3) the inclusion of nanoscale materials for improved material performance; 4) the need for quick and reliable joining methods as well as repairs; 5) more standardized design and testing methods for faster and more affordable material certifications and qualifications; and 6) better methods for recycling and reusing composites. Digging down into these issues, presenters pointed out some of the needs that must be addressed to meet these challenges. These include faster-curing resins, coupled with automation, for scalable, reproducible processes. For the success of SHM, sensors must be able to be embedded without affecting part properties, and some rules should be put in place for how to employ SHM more effectively. In the area of nano technology, scalable, affordable production of additives is a must. With metal fasteners still the norm, more reliable bonding methods are sorely needed as well as simpler repair technologies — coupled with seamless nondestructive inspection (NDI). Perhaps the biggest issue, however, is that testing and certification with current testing schemes can take years, so “virtual” material property verification methodology making use of computational models has to occur, said Zhang. The group will also try to develop new methods for recycling, and find markets and customers for recycled fiber. The goal of the consortium is to create a domestic, innovative ecosystem to accelerate adoption of advanced composites with a much shorter time to market and better technology transfer, to avoid the “valley of death” scenario that often occurs when a new technology is developed before markets and funding are ready. Advanced Material Solutions Composite and Wafer Machining IKONICS AMS employs a unique machining technology, minimizing substrate compromise and maximizing perforation variety, including non-circular perforations on complex-curved, irregular surfaces. IKONICS AMS is particularly beneficial in applications featuring challenging material, ie: Carbon Matrix Composites (CMC), Ceramic Composites, and other brittle substrates. See us at Booth #1830 IKONICS Advanced Material Solutions 4832 Grand Avenue, Duluth, MN 55807 USA direct: (218) 624-6443 | toll free: (800) 328-4261 ext.358 | web: www.ikonicsams.com | email: [email protected] An IKONICS Company ISO 9001 Certified ITAR Compliant NASDAQ Listed: IKNX www.theCAMX.org/mobile 7 THE COMPOSITES AND ADVANCED MATERIALS EXPO CAMX FAQ: Past, present and future of the show CAMX 2014 is an inaugural event and unique in that it combines the resources and efforts of two composites-related organizations: the American Composites Manufacturers Assn. (ACMA, Arlington, Va.) and the Society for the Advancement of Material and Process Engineering (SAMPE, Covina, Calif.). ACMA and SAMPE each used to host its own composites-related trade show, but composites industry evolution over the last few years has made a joint show not only practical, but necessary. Some frequently asked questions about the organizations and the show: Q: Why have ACMA and SAMPE joined forces to coproduce CAMX? A: The boards of both organizations recognize that as the industry emerges from the recession, we are facing new challenges and competition. Companies of all kinds are looking for new materials, processes, research and contacts. Composites and advanced materials are uniquely positioned to solve many of the challenges faced by government mandates, as well as environmental and societal concerns. As a result, new markets are opening for composites and advanced materials. As these new opportunities emerge, SAMPE and ACMA recognize the value of combining the strengths of their annual trade show and convention into CAMX. This event provides increased value and truly meets the needs of members as well as the much broader composites and advanced materials community. Q: Did ACMA and SAMPE merge into one organization? A: No, ACMA and SAMPE maintain their distinction as separate organizations with different goals and objectives. However, the two organizations jointly produce CAMX — The Composites and Advanced Materials Expo. Q: Will ACMA and SAMPE still host their current shows and conferences? A: CAMX is replacing both organizations’ primary annual events, which are typically held in the spring. This includes ACMA’s COMPOSITES Exhibition and Convention, and SAMPE’s Annual Spring Convention. Each organization will continue to hold other conferences, workshops and exhibitions as determined by their respective boards of directors and members. Q: What is the focus and purpose of CAMX? the application — transportation, aerospace, marine, wind energy, software, construction and infrastructure, medical, academics, sports and leisure — CAMX is America’s go-to event for products, solutions, networking and advanced industry thinking for all market segments. Q: Who owns CAMX? A: The new event is owned and produced equally by ACMA and SAMPE, with Gardner Business Media (publisher of CompositesWorld and the CAMX Show Daily) as the official media partner. These three organizations are the primary composites and advanced materials organizations in the U.S., and by attending CAMX you are helping to support the composites and advanced materials industry. Q: Where and when is CAMX 2015 taking place? A: CAMX 2015 will be held Oct. 26-29, 2015, at the Dallas Convention Center in Dallas, Texas. A: CAMX serves the entire composites and advanced materials industry. It will be the one source for connecting and advancing all aspects of the world’s Composites and Advanced Materials communities: R&D, engineering, manufacturing, service providers and end-users. Regardless of EXHIBIT HOURS Wednesday, October 15 9:30 a.m. to 5 p.m. Thursday, October 16 9:30 a.m. to 12 p.m. Upcoming SAMPE Seminars SAMPE Seminars provide valuable, in-depth education in high-interest subject areas. Choose from one of our upcoming seminars and visit www.nasampe.org for a complete list of all upcoming SAMPE Seminars and Conferences. For more information and to register visit www.nasampe.org. Contact: Priscilla Heredia P: +1.626.331.0616 x610 E: [email protected] 8 Wednesday, October 15, 2014 2-Day Seminar - Sandwich Structures Seminar October 27-28, 2014 / Anaheim, CA This seminar is specifically designed for engineers who are responsible for the design and fabrication of sandwich structures. The application of composite materials as the facing material is of particular interest and a focus of the seminar. 2-Day Seminar - Tooling Design and Materials Overview for Composite Manufacturing Sign Up TODAY November 11-12, 2014 / Irving, TX This seminar is intended for tooling engineers, tool designers, tool fabricators, and anyone else interested in tooling for composites. The two-day workshop is an interactive event where audience discussions about relevant tooling applications and questions about current projects are encouraged. CAMX highlights on the floor By Ginger Gardiner CompositesWorld Magazine compositesworld.com fiber molding compound in automotive roof bows and heavy truck underhood applications as well as arms and legs for Ferno’s iN∫X Integrated Patient Transport and Loading System. TCG is also introducing two new materials: PremierUV for high ultraviolet radiation resistance and PremierLT with a specific gravity as low as 1.2 for lightweight applications. The CAMX 2014 exhibit floor is packed with plenty of new material and process innovations not to be missed. Highlights from a first walkthrough include the DolphiCam (Booth 3354) ultrasound camera approved for use on the Boeing 787 Dreamliner’s carbon fiber composites. This handheld system enables dry coupling and produces 2-D and 3-D images, as well as A-, B- and C-scans of suspected damage areas. Another NDT must-see is The Ultran Group’s (Booth 2176) U710 noncontact (air-coupled) inline ultrasonic system for 100 percent inspection of uncured composite parts or materials (e.g., prepreg) and cured parts, including defects, delamination, porosity, density, thickness and level of impregnation (LOI). Braided crash cones, utility poles and other structures are shown at Highland Composite Structures (Booth 3961), a new subsidiary of Tokyo, Japan-based technical textiles leader Takata. Announced in May, the company’s new 62,000-ft2 facility in Statesville, N.C., will produce preforms using braiding and other textiles, as well as parts for aerospace, automotive, industrial and sporting goods using resin transfer molding (RTM) and resin infusion. Also new is L&L Products’ (Booth 3953) reformable epoxy adhesive film, combining the adhesion of epoxy with the processing ease and flexibility of a thermoplastic. In the reverse, Arkema’s (Booth 3761) new Elium thermoplastic resin offers recyclability with a material that is liquid at room temperature and is easily processed like a thermoset with RTM and infusion. Its new Nanostrength additive toughens thermoset resins without the processing and property issues of traditional thermoplastic particle tougheners, absorbing twice the impact energy with a concentration of only 2 percent compared to the legacy materials and typical 15 to 30 percent concentrations required. The Composite Group (TCG, Booth 3369) showcases the use of AMC 8590 carbon NASCAR is going carbon! See the parts from Composite Resources using Cytec resins (Booth 3745). Meanwhile, CCP Composites (Booth 2451) is displaying ENVIROGUARD flax fiber composites for automotive and Hennecke (Booth 3175) shows off a polyurethane (PUR) composite dashboard for the Audi R8 and the world premiere of its ClearRIM technology for transparent polyurethane composites. www.theCAMX.org/mobile 9 THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Ultrasonic inspection equipment The Ultran Group (State College, Pa.) is featuring its U710 ultrasonic inspection system, a next-generation, turnkey solution equipped with patented transducers, a reportedly powerful software suite and robust hardware. Optimized for use in noncontact (air-coupled), immersion and direct/delayed-contact conditions, the U710 operates in either dual- or single- (pulseecho) transducer modes. Ultran Group says the system features faster processing speeds and higher sensitivity than other noncontact quality inspection systems in the industry. The company is hosting live demonstrations in Booth 2176 and encourages attendees to bring in samples to assess the inspection system in real time. In the conference, Anuj Bhardwaj, president and CEO, is presenting a paper titled “Application of Advanced Non-Contact Ultrasound for Composite Material Qualification,” which will highlight and provide examples of how noncontact ultrasound can be implemented in production quality control for composite materials. The presentation takes place in the Testing and Measurement track on Wednesday, Oct. 15, 10 a.m. in W221 B. The Ultran Group, Booth 2176 Resins, curatives, modifiers, toughening agents Thermoplastic composites and fabrication CVC Thermoset Specialties (Cuyahoga Falls, Ohio) is featuring its line of resins, curatives, reactive modifiers and toughening agents to deliver enhanced performance in composites and thermoset formulations in Booth 1837. CVC says its materials demonstrate improved interlaminar toughness of glass, carbon and organic fiber-reinforced epoxy, as well as processing flexibility for a range of composite processes. The group has added two new VTBNX products to its line of Hypro reactive liquid polymers (RLP): Hypro 1300X33LC and Hypro 1300X43LC. The technology behind these methacrylate-terminated liquid rubbers is an innovation that allows what CVC says is superior viscosity stability and lighter color than the previous generation of Hypro VTBNXs. This technology extends the shelf life and processing window and expands the use to applications where color is important, while also improving key mechanical properties, toughness, impact resistance and flexibility. Other products include Hypro reactive liquid polymers, EPALLOY specialty epoxy resins, HyPox elastomer-modified epoxy resins, ERISYS reactive modifiers, and OMICURE catalysts and accelerators. CVC Thermoset Specialties, Booth 1837 Thermoplastic resin and fiber and tape placement specialist Automated Dynamics (Schenectady, N.Y.) is featuring in its Booth 1845 several parts and structures it has helped develop, including a helicopter tail boom, thermoplastic drive shafts, thermoplastic floor Balsa and PVC core materials CoreLite Inc. (Miami, Fla.) is emphasizing the company’s two primary core materials, Balsasud balsa wood and CoreLite Board PVC foam board. Balsasud balsa is grown, harvested and milled in CoreLite-owned and operated farms and facilities in Ecuador. The Balsasud S.A. facility in Ecuador has been Forest Stewardship Council (FSC) certified by the Rainforest Alliance according to FSC Chain of Custody standards. Final processing into finished core materials is done in CoreLite’s Miami facility, the newest balsa production facility in North America. CoreLite says that controlling production from forest to end-user assures Balsasud customers panels and more. Also at the booth are videos of the company’s fiber placement equipment in process, as well as information on its laser heating for automated fiber placement (AFP). In the conference, David Hauber, VP of engineering, is presenting “Recent Advances in In-situ Automated Fiber Placement of Thermoplastic Matrix Composites,” Wednesday, Oct. 15, 8 a.m., W221 B. Automated Dynamics, Booth 1845 the highest quality balsa core products. CoreLite Board is a closed-cell PVC foam specially formulated to provide good physical properties. It is engineered to meet demands required for use in marine transoms, attachment points, floors, bulkheads, stringers, local reinforcement points, molds and tooling. CoreLite Board is a stand-alone product and can be used with or without composite skins as a direct replacement for wood and plywood. The company says it has good fastener pullout strength, high flexural strength and stiffness, and is 27 percent lighter than plywood. CoreLite Inc., Booth 2985 High-performance fabrication services Wednesday, October 15, 2014 3 B a p a ( c ATK Aerospace Structures (Clearfield, Utah) is emphasizing its patented, automated technologies for domestic and international commercial, military and large launch vehicle products in Booth 1731. Specifically, ATK is featuring its Automated Stiffener Forming technology, used to manufacture commercial aircraft stiffeners and frames; the technology can be extended to many other applications for high-performance composite structures. ATK says these technologies enable it to produce high-quality, dimensionally precise and highly repeatable composite components at a high rate of production. In the conference, Bill Hooper, ATK Aerospace Structures Division senior manager of R&D 10 M Engineering, will present “Advancements in Automated Fabrication and Inspection of Aerospace Grade Composite Structures,” Wednesday, Oct. 15, 9:30 a.m., in W221 B. ATK Aerospace Structures, Booth 1731 s y w 2 Product News at CAMX 2014 No-oven, no-autoclave matrix resin Cornerstone Research Group (CRG, Dayton, Ohio) and its two newly launched subsidiaries—NONA Composites and Advantic—are all represented in Booth 2355. Additionally, the subsidiary that CRG launched in 2010—Spintech (Smart Tooling)—is also at the show, in Booth 3461. CRG launched NONA Composites and Advantic in early 2014 as part of its long-held strategy of growth through commercialization of its advanced materials R&D capabilities. NONA Composites and Advantic each apply advances in materials technology and manufacturing process to industry challenges to provide significant value for their customers. NONA Composites provides no-oven, no-autoclave (NONA) composite resin, tooling and part fabrication solutions. Freeing part manufacturers from traditional curing infrastructure, NONA Composites says its products and services allow customers to rapidly produce tooling and parts and to realize significant cost savings, increased throughput and greater manufacturing flexibility. Advantic provides value engineering and manufactures lightweight, high-performance, structural polymer composite building materials. Integrated building, remediation and remodel solutions allow customers to design, specify, bid and build more competitively by reducing design and building labor costs, building material costs and project duration or site shut-down time. In the conference, Ben A. Dietsch, COO, presents “No-Oven, No-Autoclave Composite Tool Fabrication,” Wednesday, Oct. 15, 9 a.m., W222 B. Michael Rauscher presents “No-Oven, No-Autoclave Cure of Prepreg Structures,” Wednesday, Oct. 15, 11 a.m., W224 F. Cornerstone Research Group, Booth 2355 Cold chain management solutions DeltaTrak (Pleasanton, Calif.), a developer of cold chain management solutions, showcases its latest FlashTrak Telematics Out-Time Monitoring Solution. This RF wireless system automatically calculates and records the amount of time that carbon fiber prepreg and other time- and temperature-sensitive materials (TATS) are outside of cold storage environments. DeltaTrak’s FlashTrak Telematics offers real-time visibility of TATS materials during storage and handling. Out-time data is archived for analysis and audits, as well as to comply with regulatory guidelines. The system integrates into standard operating procedures and reportedly does not require large capital equipment expenditure. DeltaTrak, Booth 3275 MEET THE MARK ONE™: THE WORLD’S FIRST COMPOSITE 3D PRINTER. 3D PRINT CARBON FIBER. Brilliant ideas need brilliant materials. The Mark One™ uses a patent pending Composite Filament Fabrication (CFF™) process to 3D print continuous strand carbon fiber, Kevlar®, and fiberglass. Utilizing the CFF™ print head and one FFF (Fused Filament Fabrication) print head, the Mark One can create astonishingly robust parts by reinforcing MarkForged’s special blend of nylon with continuous fiber filaments. Now you can 3D print functional parts with a higher strength-toweight ratio than 6061-T6 aluminum – at your desk. VISIT US AT BOOTH 1533 Kevlar® is a registered trademark of DuPont E.I. du Pont de Nemours and Company or its affiliates. 20x stiffer than ABS. 5x stronger than ABS. Carbon Fiber • Kevlar® • Fiberglass Nylon • PLA 11 www.theCAMX.org/mobile LEARN MORE AT MARKFORGED.COM THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Thermoplastic honeycomb core In Booth 1986, thermoplastic honeycomb core specialist EconCore (Leuven, Belgium) is emphasizing its ThermHex honeycomb technology, the RENOLIT Gorecell line and the LANXESS Tepex line. The ThermHex line includes polypropylene (PP), the most widely used, polyethylene terephthalate (PET), bioplastics, polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), polystyrene (PS), polycarbonate (PC), polymethyl methacrylate (PMMA), polyamide (PA), polyphenylene sulfide (PPS) and others. In-line with the core production, skins can be laminated onto the honeycomb directly after the core is made. ThermHex Waben, EconCore’s daughter company in Germany, produces the ThermHex PP honeycomb core material for composite applications. The thickness of this honeycomb core material typically ranges from 3 mm/0.12 inch to 30 mm/1.2 inches. Its density can vary from 40 kg/m3 to 200 kg/m3, offering a compression strength as high as 6 MPa. RENOLIT Gorecell combines the RENOLIT WOOD-STOCK product with an ultralight honeycomb structure. This results in a thermoplastic lightweight panel with wood-plastic composite sheets on the top and the bottom, which give an aesthetic and natural character to the panel in addition to having high stability and stiffness. Recently EconCore joined forces with Lanxess to develop new thermoplastic sandwich materials, called Tepex, for automotive applications. The cores are made from Durethan polyamides with the help of an automated, continuous process patented by EconCore. In addition, Tepex continuous fiber-reinforced thermoplastic composites from LANXESS subsidiary Bond-Laminates can be combined with the new polyamide honeycomb cores to produce high-performance composites. This combination reportedly opens up new possibilities in lightweight construction — for example, high loadbearing structural automotive parts. EconCore, Booth 1986 Design and analysis software Componeering (Helsinki, Finland) is introducing ESAComp 4.5, the latest version of its software for composite design and analysis, which includes a major new feature for composite pressure vessels. The new module uses input from the ComposicaD filament winding process simulation tool by Seifert and Skinner & Assoc. The combination of ComposicaD and ESAComp is said to provide an efficient and economical means of reliable process and design simulation, design verification, and manufacturing. The ESAComp structural analysis follows the winding simulation performed by ComposicaD. The analysis results, such as layer stresses, strains and failure margins, can be shown as contours over the pressure vessel geometry and further studied as through-the-thickness charts. Also new, for HyperWorks users, ESAComp now offers a composite postprocessing interface. Developed jointly with Altair Engineering, this interface reportedly allows smooth transfer of finite element analysis results to ESAComp where advanced composites failure criteria can be applied. Detailed analysis results are further returned to HyperWorks for display with the model geometry. Componeeering Inc., Booth 3661 Glass fiber technologies PPG Industries (Pittsburgh, Pa.) is showcasing its portfolio of fiberglass products and technologies in Booth 3161, as well as presenting two technical seminars at CAMX 2014. Featured in the booth are GL-certified HYBON direct roving, INNOFIBER specialty fiberglass compositions and TUFROV long-fiber thermoplastic rovings. Materials from PPG is also available for its other reinforcement materials and industrial and specialty yarns. In the conference, Ryan Emerson, Ph.D., PPG group leader for applications development, 12 Wednesday, October 15, 2014 in collaboration with Brandon Strohminger, A&P Technology applications engineer, presents “Crash Performance of Variable Stiffness Braided Fiber Glass Composites,” Wednesday, Oct. 15, 4 p.m. in W224 H. Pu Gu, PPG senior research associate, and James C. Watson, associate director for PPG Fiber Glass Science & Technology, present “Corrosion Resistance of E-Glass Fiber Reinforced Composites: Boron and Interface Factors,” Wednesday, Oct. 15, 4:30 p.m. in W224 E. PPG Industries, Booth 3161 Release agents, casting lubricants Chem-Trend (Howell, Mich.), a developer and producer of high-performance release agents and casting lubricants, is emphasizing that it has achieved the highest global certificate of registration for its quality management systems at two manufacturing facilities in Howell. The NSF-International Strategic Registrations (NSF-ISR, Ann Arbor, Mich.) recognized Chem-Trend’s Grand River and McPherson Park plants for conforming to the AS9100 requirements for aviation standards. This certificate of registration validates the plants’ quality management programs. “By receiving this certificate of registration at two of our locations, Chem-Trend is demonstrating its continued commitment to the international standard for the aerospace industry,” says Devanir Moraes, Chem-Trend president and CEO. “Chem-Trend has a long-standing history of placing a significant priority on quality manufacturing processes. This certificate acknowledges that our quality management system adheres to rigorous global scrutiny.” Manufacturers and suppliers in the aircraft and aerospace industries embrace AS9100 as a global standard and a critical tool for improving quality and on-time delivery within their supply chain. Most companies in the aerospace industry endorse or require certification to AS9100 as a condition of doing business. Chem-Trend LP, Booth 3083 Compression molding machinery Compression molding machinery manufacturer TMP (Piqua, Ohio), a division of French Oil Mill Machinery Co., features its line of 15- to 2,000-ton presses for all types of composite and thermoplastic parts production in Booth 1975. TMP’s machines include the advanced “Edge” control systems, which feature a user-friendly touch-screen operator interface that allows programmable profiles with multiple setpoints for pressure, time, hydraulic flow rates and ram velocity and can be integrated into existing plant supervisory control and data acquisition systems. TMP also services machines and offers machine rebuilding and upgrades for increased automation. TMP, Booth 1975 Product News at CAMX 2014 Reformable epoxy adhesive film L&L Products (Romeo, Mich.), a global applied engineering and materials science company, launches L-F610, a unique reformable epoxy adhesive film, in Booth 3953. The product combines the adhesion and mechanical properties of an epoxy with the processing ease of a thermoplastic. L&L says L-F610 will facilitate new opportunities for the manufacture of composite parts, panels and laminates. With a tensile elongation of 40 percent, this reformable epoxy adhesive film is said to offer high toughness with better strength and adhesion than traditional thermoplastic adhesive systems. L-F610 has the ability to not only adhere to many different substrates — metals, epoxy composites, plastics and wood — but can also be readily used for a wide range of dissimilar substrate bonding applications. It can be de-bonded and reformed allowing parts and components to be modified in existing structures. L-F610 is also dry to the touch and transparent, which reportedly makes it ideal for applications where a good cosmetic finish is required. Unlike epoxy thermoset film adhesives, L-F610 does not require refrigerated storage and has a long shelf life. In order to explore further applications for this new product, L&L Products has formed a relationship with Hardwire LLC (Pocomoke City, Md.), a U.S.-based composite components fabricator. George Tunis, Hardwire CEO, says, “Although thermoset systems have their place in composite manufacturing, thermoplastics are unbeatable in convenience, processing speed, recyclability and toughness. L&L’s L-F610 is the first film that has a magic blend of toughness, Tg, processing temperature and modulus. It’s perfect for products requiring high stiffness, damping and extreme toughness. Stampable composites, including renewable natural fiber composites are now possible, allowing the entire manufacturing process to be fully automated.” L&L Products, Booth 3953 Subscribe today! • E x p lo r e t h e la t e s t n e w s , t r e n d s a n d u p o s s ib ilit ie s in t h e in d u s t r y . • F ree p r i n t a n d d i g i t a l s u b s c r i p t i o n s u a v a ila b le fo r a ll m e m b e r s o f t h e c o m p o s it e s in d u s t r y ! CompositesManufacturing Laser monitoring and control In Booth 2953, Assembly Guidance Systems (Chelmsford, Mass.) is featuring its LASERGUIDE Software Development Kit (SDK), which enables composites manufacturers to integrate laser monitoring and control into their automated work cells, such as automated fiber placement (AFP) operations. The SDK is a DLL-based driver with a library of API, thus a work cell’s controller can directly operate the LASERGUIDE projector. Using the SDK, manufacturers can instantly display design data and accurate dimensional references, automatically detect FOD, and measure and document critical parameters such as fiber orientation. Assembly Guidance says that in U.S., European and Asian implementations of the SDK, manufacturers have realized a five-fold reduction in projection error, and cycle-time reduction of as much as 80 percent. Assembly Guidance Systems, Booth 2953 Exhibit at CAMX 2015 October 26-29, 2015: Conference October 27-29, 2015: Exhibits Dallas Convention Center Dallas, Texas, USA July/August 2014 The Official Magazine of the American Composites Manufacturers Association Trailblazing Bridges www.theCAMX.org High-Performance Composites Prime Booth locations are now available. US Army Applications www.compositesmanufacturingmagazine.com A M E R I C A N C O M P O S I T E S M A N U FA C T U R E R S A S S O C I AT I O N Visit the CAMX Exhibits sales team in the Exhibitor Lounge, located in the 1700 aisle. Produced by G e t Y o u r F r e e S u b s c r ip t io n a t CompositesManufacturingMagaz ine.com www.theCAMX.org/mobile 13 THE COMPOSITES AND ADVANCED MATERIALS EXPO Product News at CAMX 2014 Thin-ply fiber reinforcement Chomarat (Anderson, S.C.) is featuring its C-PLY thin-ply fiber reinforcement systems, emphasizing the carbon roof/polyurethane roof panel for the Roding Roadster, made via resin transfer molding (RTM). “Indeed, Chomarat’s carbon reinforcements in automotive structures and external hang-on body panels requiring a class A finish are efficient and competitive solutions. We have developed with our partners a solution saving time-consuming rework, which can amount to up to 60 percent of the costs per component,” says Francisco De Oliveira, automotive market director at Chomarat. C-PLY is also used in the VX1 KittyHawk, which is competing in the Awards for Composites Excellence (ACE) and the CAMX Awards (see the Awards Pavilion in the Exhibit Hall). The hybrid aircraft, designed and manufactured by VX Aerospace, minimizes its environmental footprint thanks to being powered by compressed natural gas (CNG). The first flight of the subscale aircraft took place in the U.S. on June 6, 2014. For railway and construction applications, Chomarat has developed ROVICORE FR, a fire-resistant reinforcement featuring glass fiber-based reinforcement with a halogen-free core. Chomarat North America LLC, Booth 2683 COMBINED STRENGTH. UNSURPASSED INNOVATION. October 13-16, 2014: Conference / October 14-16, 2014: Exhibits Elite Sponsors Supporter Sponsors Contributor Sponsors 14 Wednesday, October 15, 2014 High-speed filament winding equipment Entec Composite Machines (Salt Lake City, Utah) is performing live demonstrations of its new FW750 filament winder and high-speed ST1 servo tensioner in Booth 3561. The company also highlights its full range of filament winding machines and application solutions. The FW750 filament winder and high-speed servo tensioner are designed to provide accurate, high-speed and cost-effective filament winding for use in a range of applications, including pressure vessels for compressed natural gas (CNG) storage. It offers winding speeds in excess of 135 inches/sec and a performance accuracy of ±0.2 lb. During the live demonstrations, Entec will wind CNG fuel tanks using Zoltek’s Panex 35 TowPreg, a pre-impregnated carbon fiber tow. When paired with Panex 35 TowPreg, the FW750 reportedly achieves greater fiber placement control due to the increased tack of material. This results in increased design freedom and more accurate burst pressure predictions when compared to traditional wet winding. The elimination of resin bath results in faster winding speeds, cleaner operations, and an overall faster production throughput. Entec Composite Machines, Booth 3561 The most important thing we build is trust Excellence in Advanced Composite Production and Design Solutions Cobham is recognised as an industry leader for the design, development and manufacture of a wide range of composite structures. Cobham’s composite business units cover all composite processes including Resin Transfer Molding (RTM), Compression Molding, Hand Lay-up / Autoclave Cure, Advanced Bladder Molding and Filament Winding. Cobham’s award-winning composite products include aircraft engine components, aircraft and spacecraft structures, missile and munitions assemblies, pressure vessels, flywheel rims and radomes. Advanced Composite Solutions Ladder Brackets Composite Fan Blades Acoustic Panels Infill Panels Exhaust Flaps Spinner and Cap Terminal/Speed Probe Blocks Cobham Composite Products fabricates complex, hightolerance composite parts and assemblies including hightemperature engine components used on both military and commercial aircraft. Our 72,000 sq-ft facility located in San Diego, CA houses state-of-the-art compression molding presses that are automated and we utilize mechanized layup processes that are robust and repeatable to guarantee part to part consistency. Strategic Company Focus • High Temperature Aircraft Engine Components • Aircraft Engine Components and Structures Stator Vanes Ice Impact Panels Composite Fan Blades Advanced Design Solutions With core capabilities in energy storage and control, filament winding and metal to composites bonding, Cobham Life Support, in Westminster, MD produces innovative composite structures including the world’s first demisable spacecraft propellant tank, pressure vessels and flywheel rims all while meeting the most demanding weight, strength and safety requirements. Strategic Company Focus • • • • • Energy Storage Ultra-High Pressure Cylinders Aircraft Emergency Inflation and Oxygen Systems Spacecraft Components Military Rotorcraft Structures For sales inquiries or more information, please contact: Cobham Composite Products - San Diego, CA, USA T: 001 (858) 824 8958 Cobham Life Support - Westminster, MD, USA T: 001 (410) 871 9966, ext106 Visit Cobham at CAMX 2014 - Booth# 4453 www.cobham.com Make it Precision Board Plus High Density Polyurethane Tooling Board and Core Material • Custom tooling blocks • Closed cell structure • Custom carving blocks • No out-gassing • Custom mandrels • 15 standard densities • Exceeds aviation flammability standards • 8 sheet sizes up to 24” thick (800) 845-0745 www.precisionboard.com Visit us at CAMX Orlando Oct. 14-16 Booth #4157

© Copyright 2026