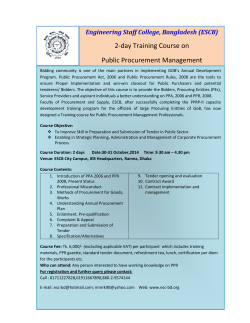

Chapter 4 Procurement and Supply Management 1

Chapter 4 Procurement and Supply Management Chapter 4 1 Material Management Electronic Procurement – e-Commerce Chapter 4 Management of Business Logistics, 7th Ed. 2 Material Management Chapter 4 Management of Business Logistics, 7th Ed. 3 Inbound Logistics along the Supply Chain Each firm in the food system supply chain graphic in Figure 4-1 has important differences in their inbound logistics systems. Mining firm Steel firm Container firm Food firm Retail outlet Individual firm complexity Chapter 4 Management of Business Logistics, 7th Ed. 4 Figure 4-1 A Food System Supply Chain Important note: one ends with customers may serve as the other End as vendor value Chapter 4 Management of Business Logistics, 7th Ed. 5 Table 4-1 Industry Supply Chain Logistics Emphasis Chapter 4 Management of Business Logistics, 7th Ed. 6 Materials Management Definition - Materials management is the planning and control of the flow of materials that are part of the inbound logistics system. Materials Management Activities (procurement, warehousing, production planning, inbound transportation, receiving, materials quality control, inventory management, and salvage and scrap disposal) 1. 2. 3. 4. Chapter 4 Procurement Importance of Item and Service Purchased The Special Case of Procurement Price Other Materials Management Activities Management of Business Logistics, 7th Ed. 7 Materials Management: 1.Procurement Buying goods and services for a firm, a process of obtaining goods and services for the firm Importance Contributes to the competitive advantage of the firm Significant portion of the logistics costs Chapter 4 Management of Business Logistics, 7th Ed. 8 Materials Management: 1.Procurement Definition of Procurement 12 Activities 1. Identify or reevaluate needs 2. Define and evaluate user requirements 3. Decide whether to make or buy 4. Identify the type of purchase 5. Conduct a market analysis 6. Identify all possible suppliers Chapter 4 Management of Business Logistics, 7th Ed. 9 Materials Management: 1.Procurement Definition of Procurement Activities… 8. Prescreen all possible sources 9. Evaluate the remaining supplier base 10. Choose a supplier 11. Receive delivery of the product or service 12. Make a post purchase performance evaluation (see next slide for the flows) Chapter 4 Management of Business Logistics, 7th Ed. 10 Figure 4-2 1.Procurement Process Chapter 4 Management of Business Logistics, 7th Ed. 11 Materials Management: 2.Importance of Item and Service Purchased Products and services purchased by a company are not all the same. Some are more important than others and require greater procurement attention. The quadrant technique enables the supply chain manager to assess the relative importance of each item based on the degree of perceived value and risk. Chapter 4 Management of Business Logistics, 7th Ed. 12 Materials Management: 2.Importance of Item and Service Purchased There are four possible combinations in the quadrant techniques model: Generics --- low risk, low value Commodities --- low risk, high value Distinctives --- high risk, low value Criticals --- high risk, high value Figure 4-3 illustrates the relationships in the quadrant technique model. Chapter 4 Management of Business Logistics, 7th Ed. 13 Figure 4-3 2Item Procurement Importance Matrix Chapter 4 Management of Business Logistics, 7th Ed. 14 Materials Management: 2. Managing the Procurement Process in 4 Steps 1. Determine the type of purchase New purchase Straight rebuy Modified rebuy Chapter 4 Management of Business Logistics, 7th Ed. 15 Materials Management: 2. Managing the Procurement Process in 4 Steps 2. Identify levels of investment Determine the necessary levels of investment of time and information. The more complex the purchase, the more time needs to be spent and more information needs to be gathered to get it right the first time. Chapter 4 Management of Business Logistics, 7th Ed. 16 Materials Management: Managing the Procurement Process in 4 Steps 3. Perform the procurement process Do those activities that are necessary to effectively make a purchase and satisfy the user’s requirements. 4. Evaluate the effectiveness of the procurement process Were the user’s needs satisfied? Was the investment necessary? Chapter 4 Management of Business Logistics, 7th Ed. 17 Materials Management: 2.Managing the Procurement Process Supplier/Vendor Evaluation and Relationships Maintaining a healthy vendor relationship is a critical part of a successful supply chain. Developing a true partnership relationship with a firm’s vendors grows more important as the number of vendors shrinks and/or the vendors are being sought by other competing supply chains. TQM begins with the vendors. Chapter 4 Management of Business Logistics, 7th Ed. 18 Materials Management: 2.Managing the Procurement Process Vendor Selection Criteria 1. Quality 2. Reliability 3. Capability 4. Financial 5. Miscellaneous Other Qualities 6. Vendor Location 7. Factor Importance Will Vary Chapter 4 (Itemized see next slide) Management of Business Logistics, 7th Ed. 19 Figure 4-4 Overview of Vendor Selection Criteria Chapter 4 Management of Business Logistics, 7th Ed. 20 Materials Management: 3. The Special Case of Procurement Price 1. Sources of Price 1. Commodity markets 2. Price lists 3. Price quotations 4. Negotiation Chapter 4 Management of Business Logistics, 7th Ed. 21 General spectrum of expanding procurement approaches to the supply chain ---- see next slide Chapter 4 Management of Business Logistics, 7th Ed. 22 Figure 4-5 Hierarchy of Price Measurement Approaches Chapter 4 Management of Business Logistics, 7th Ed. 23 Components required to be considered in order to obtained overall optimized solution (see next slide) Chapter 4 Management of Business Logistics, 7th Ed. 24 Figure 4-6 Total Procurement Price See next slides For details Chapter 4 Management of Business Logistics, 7th Ed. 25 Materials Management: The Special Case of Procurement Price 2. Types of Costs 1. Traditional basic input costs - primary product price 2. Direct transaction costs - all other related costs of detecting and transmitting information to suppliers (e.g., EDI) 3. Supply relational costs - costs of maintaining relationships with suppliers Chapter 4 Management of Business Logistics, 7th Ed. 26 Materials Management: The Special Case of Procurement Price 3. Other types of Costs 4. Landed costs actual transport costs + sales terms 5. Quality costs/factors do the goods conform to standard? Chapter 4 Management of Business Logistics, 7th Ed. 27 Materials Management: The Special Case of Procurement Price Other types of Costs 6. Operations/logistics costs Receiving and make-ready costs Lot size costs Production costs Other logistics costs affected by product’s size, weight, density and shape Chapter 4 Management of Business Logistics, 7th Ed. 28 Materials Management: 4. Other Materials Management 5 Activities 1. Warehousing Type of facilities required 2. Production Planning and Control Coordinating product supply with product demand (such as open air …Chapt 8) (forecasting, see Figure 4-7) Chapter 4 3. Transportation Vendor control Modal choice Rush shipments Inspection Damage claims Management of Business Logistics, 7th Ed. (rail, water..) 29 Figure 4-7 Overview of Production Planning and Control Chapter 4 Management of Business Logistics, 7th Ed. 30 Materials Management: Other Materials Management Activities 4. Quality Control Quality standards did customer receive what was ordered? Quality implications GIGO concept Sample inspection statistical QC from vendor to assure 100% quality Chapter 4 Management of Business Logistics, 7th Ed. 31 Materials Management: Other Materials Management Activities 5. Salvage and Scrap Disposal Value of scrap may be income to the firm. Disposal must adhere to environmental regulations. Chapter 4 Management of Business Logistics, 7th Ed. 32 Electronic Procurement Chapter 4 Management of Business Logistics, 7th Ed. 33 Electronic Procurement Business-to business (B2B) purchases are estimated to be $1.3 to $2.0 trillion by 20036. Former uses of electronic data interchange (EDI) were costly and required special technology to implement have given way to the publicly available Internet. This has opened the door to increased applications of E-commerce techniques to procurement. Chapter 4 Management of Business Logistics, 7th Ed. 34 Electronic Procurement 6 Common uses of E-commerce 1. Research vendor and product information 2. Electronic check of available stock 3. Price negotiation 4. Order products or services 5. Check on the status of an order 6. Issue invoice and receive payment Chapter 4 Management of Business Logistics, 7th Ed. 35 Electronic Procurement Advantages of E-commerce outlined in Figure 4-8. Disadvantages Security of electronic messages Lack of face-to-face contact Other technological concerns Chapter 4 Standard protocols System reliability Management of Business Logistics, 7th Ed. 36 Figure 4-8 Advantages of Electronic Procurement Chapter 4 Management of Business Logistics, 7th Ed. 37 Four Basic Types of E-commerce Models7 1. Sell-side system Administered by the seller Usually free to the buyer (B2B) www.officemax.com, www.globalcomputer.com, 2. Electronic marketplace Administered by a third party Collection of electronic catalogs One-stop sourcing for buyers Chapter 4 www.plasticsnet.com, www.e-chemicals.com, www.metalsite.com Management of Business Logistics, 7th Ed. 38 Types of E-commerce Models 3. Buy-side system Administered by the buyer Pre-approves vendor access Expensive and usually the domain of large companies ERP, will discuss more later 4. On-line trading community Maintained by a third party Used by multiple buyers and sellers www.eaby.com, www.travelocity.com, www.nte.net Chapter 4 Management of Business Logistics, 7th Ed. 39 Chapter 4: Summary and Review Questions Students should review their knowledge of the chapter by checking out the Summary and Study Questions for Chapter 4. This is the last slide for Chapter 4 Chapter 4 40 End of Chapter 4 Slides Procurement and Supply Management Chapter 4 41

© Copyright 2026