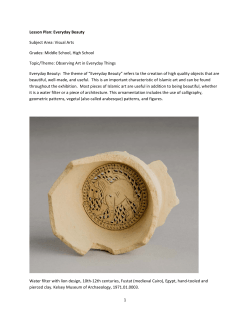

Exploring Biopolymer-Clay Nanocomposite Materials