24” Marvel Refrigerated Drawers Model # ML24RD****

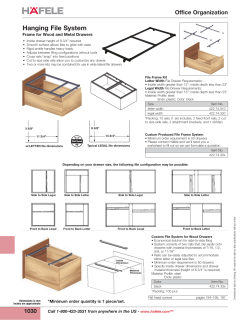

24” Marvel Refrigerated Drawers Model # ML24RD**** Certified to meet ENERGY STAR® requirements •D ynamic Cooling Technology™ delivers rapid cooldown and the industry’s best temperature stability • Specially designed for a truly flush fit with adjoining cabinetry • MARVEL Intuit™ Integrated Controls provide precise temperature management from 34°F to 42°F • Pristine arctic white interior easily wipes clean and efficient white LED lighting illuminates interior for better viewing • Insulated thermal-efficient cabinet ensures optimum efficiency and preservation • Close Door Assist System™ gently and automatically closes drawers • Audible and visual alarms signal when drawer is left ajar to protect food integrity and energy use • Vacation/Sabbath mode conserves energy during times when the unit is not in use and complies with Star-K requirements • Height adjustment up to 1” with leveling legs • 4” black adjustable toe kick • 1-year warranty Storage Capacity Up to (108) 12-oz cans Product Dimensions 23⅞” W x 33¾” minimum H x 25⅝” D (including handle) Finish/Door Options Ordering Details Solid Stainless Steel Drawer Front ML24RDS2NS Solid Black Drawer Front, Black Handles ML24RDS2NB Solid Panel Ready Drawer Front ML24RDP2NP No panel installation kit required. Stainless Steel Black Wood Overlay (Panel Ready) Forced Air Fan "A" Evaporator Plate "B" Return Air Intake Front "C" 24" Rough-In Dimensions PRODUCT "A" DIMENSIONS 24” (61 cm) "B" "C" **34" to 35" (86.4 to 88.9 cm) 24” (61 cm) PRODUCT DATA MODEL ELECTRICAL REQUIREMENTS # PRODUCT WEIGHT ML24RDS 115V/60Hz/15A 130 lbs (59 kg) 130 lbs (59 kg) Cabinet115V/60Hz/15A Dimensions ML24RDP "D" "E" "F" 23 7⁄8” (60.7 cm) 33 3⁄4” to 34 3⁄4” (85.7 to 88.3 cm) 23 23⁄32” (60.2 cm) “G” “H” 25 21⁄32” (65.2 cm) 39 5⁄32” (99.5 cm) Forced Air Fan Evaporator Plate Return Air Intake Front Side "G" "D" "F" Dynamic Cooling Technology™ delivers rapid cool down and the industry’s best temperature stability "E" The distinctive Marvel design features a thermal-efficient cabinet and door combined with Dynamic Cooling Technology™ for superior temperature stability, faster cooling 1"times and speedy temperature recovery even (2.5 cm) with high frequency. Figure 8 * Depth dimension of rough-in opening may vary depending on each individual installation. To recess entire drawer "F" dimension plus 1" (2.5 cm) for thickness of power cord plug Width 23 ⅞" Control Type is required. Interior Finish White Temperature Range ** Minimum rough-in opening required is to be larger than Lock Up to 108 12-oz cans the adjusted height of the cabinet. Capacity Electrical Requirements Shelving System 15 amp dedicated NA # A grounded circuit is required. Follow Length of Power Cord all local building codes when installing electrical and appli- Shelf Fronts ance. NA Product Dimensions Other Storage NA Depth to Front of Door Interior Lighting Toe Grill Finish Hinge Handle ! WARNING 1 White LED Pod per drawer Black NA Designer 211⁄2" (54.6 cm) "H" Intuit™ 34° - 42° F NA 120V / 60Hz / 15A 5' Finishes Yes Agency Approvals CSA ENERGY STAR Certified 23 ⅞" W x 33 ¾" H x 21 ½" D 23 23/32" Finishes Key DepthFloor to Handle 25 21/32 " installed for freestandmount Anti-tip Bracket must be applications. for5/built Depthing with door at 90° Not required 29 " in applications. SS 32 9 Shipping Weight 160 lbs SS, B, O Vacation / Sabbath Mode = Stainless Steel B = Black O = Overlay holes from the front, to the recommended diameter of the handle manufacturer. Counter bore the back-side of the panel so the screw heads do not interfere with the surface Overlay Panels of the drawer. Panel thickness 233⁄4" (603 mm) 13⁄16" (30 mm) OVERLAY 19" DRAWER PANEL INSTALLATION 23⁄8" (60 mm) (483 mm) 3: Attach the Overlay Panel to the Drawer 1"(25 mm) diameter Step counter 1. deep Set the overlay panel on drawer front face and align bore 1⁄4" (6 mm) edges. (See Figure 15 below). The custom overlay 2 places, top drawer only. 1429⁄32" (379 mm) panel should be flush with the top of the drawer and centered on the width of the drawer. Clamp panel in position and mark pilot hole locations. Pick the required pilot hole size from "Table B" below and drill the pilot holes ensuring not to drill all the way through the overlay panel. .35/.31 (9 mm/7.5 mm) .50 (12.5) Figure 14 OVERLAY DRAWER PANEL INSTALLATION Face of Table B: Pilot Hole Drill Sizes for Wood Screws Overlay Panel #8 Wood Screw (This side facing interior) Material Type 1 Figure 13 Hardwood Step 4: Reinstall the Drawers ⁄8 Diameter Pilot Hole Softwood ⁄64 Diameter Pilot Hole 7 Step 1. 2: Size the Overlay Panel Fully extend drawer slides and place drawer on slides. Cut the overlay thedrawer dimensions below 2. Insert Be panel sure to that sitsshown evenly on inboth slides andwood clipsscrews through clearance holes and Figure 14. On the top drawer only drill the 2 counter-bored tighten to secure overlay panel. slide into place in rear of drawer. holes which are clearance for screw heads on the face of 3. Reinstall gasket into channel. Make sure the corners 2. Re-install wire harness at rear corner of top drawer. the top drawer. are fully inserted. 3. Re-install two screws through drawer into slides. This is also a convenient time to locate and drill the holes ER PANEL INSTALLATION for your handle. Most often the handle is to match that of the surrounding cabinetry. If your handle attaches from the back-side of the custom panel, locate the mounting holes while the panel is attached to the drawer and cabinet. After Step Attach the Overlay the3: panel is removed from the Panel drawer, to drillthe the Drawer mounting 1. holes Set INSTALLATION the overlay paneltoon drawer front face diameter and alignof the ER PANEL from the front, the recommended edges. manufacturer. (See Figure 15Counter below). bore The custom overlayof the handle the back-side panel so should be flush with do thenot topinterfere of the drawer and panel the screw heads with the surface centered on the width of the drawer. Clamp panel in of the drawer. position and mark hole locations. Pick theDrawer required Step 3: Attach thepilot Overlay Panel to the Panel thickness pilotthe hole size from "Table B" below drill thealign pilot 1. Set overlay panel on drawer frontand face and holes ensuring not to all the way through the overedges. (See Figure 15drill below). The custom overlay lay panel. panel should be flush with the top3 of the drawer and 23 ⁄4" centered on the width of the drawer. Clamp panel in (603 mm) 13⁄16" (30 mm) Table B: Pilot Hole Drill Sizes Wood Screws position and mark pilot holeforlocations. Pick the required pilot hole size from "Table B" drill the pilot Material Type #8below Woodand Screw holes ensuring not to drill1 all the way through the over3 2 ⁄8" 19" Pilot Hole Hardwood ⁄8 Diameter lay panel. (60 mm) (483 mm) 7 Softwood ⁄64 Diameter Pilot Hole Table B: Pilot Hole Drill Sizes for Wood Screws 1"(25 mm) diameter counter 1 1429⁄32"wood screws through clearance n 2. Insert holes and deep ⁄4" (6 mm) Material Type #8 Woodbore Screw (379 mm) drawer only. PANEL red tighten to secure overlayOVERLAY panel.2 places, top DRAWER 1 Hardwood ⁄8 Diameter Pilot the Hole of 3. Reinstall gasket into channel. Make sure corners 7 ⁄64 Diameter Pilot Hole are Softwood fully inserted. 14 Screw clearance hole through gasket extrusion Figure 15a Overlay panel flush with top edge of drawer Custom overlay panel to be centered on width of drawer. INSTALLATION Step 4: Reinstall the Drawers nes 2.PANEL Insert wood screws through clearance Figure 14holes and RAWER INSTALLATION of red the of es After g es he of ethe ace es fter g he 1. Fully extend drawer slidespanel. andFace placeof drawer on slides. tighten to secure overlay sure that drawer evenly on both and clips 3. Be Reinstall gasket intosits channel. Make sureslides the corners Overlay Panel slide into placethe in rear of drawer. are fully inserted. (This side facing interior) Step 3: Attach Overlay Panel to the Drawer Set the overlay panel on drawer front face and 2. 1. Re-install wire harness at rear corner ofalign top drawer. edges. (See 15 below). The drawer custom overlay 3. Re-install twoFigure screws through into slides. ace elow in nter-bored e face of panel should be flush with the top of the drawer and centered on the width of the drawer. Clamp panel in position and mark pilot hole locations. Pick the required pilot hole size from "Table B" below and drill the pilot holes ensuring not to drill all the way through the overlay panel. Figure 15 14 Screw clearance hole through gasket extrusion Using clearance holes in gasket channel mark hole locations onto panel Table B: Pilot Hole Drill Sizes for Wood Screws Material Type #8 Wood Screw Hardwood 1 Softwood 7 ⁄8 Diameter Pilot Hole ⁄64 Diameter Pilot Hole 2. Insert wood screws through clearance holes and tighten to secure overlay panel. 3. Reinstall gasket into channel. Make sure the corners are fully inserted. Figure 15a installation instructions, For comprehensive please visit www.marvelrefrigeration.com Overlay panel

© Copyright 2026