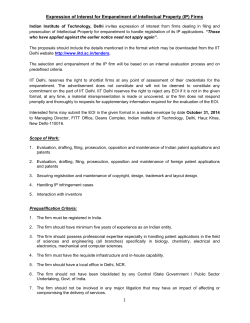

B.E. Industrial Engineering and Management