Bivee Brochure

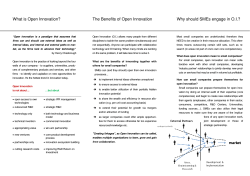

Bi vee THE PARTNERS An effective project team. Ten organisations from six European countries are committed to this three year project. Innovating Innovation FIND OUT MORE Contact us now Would like to know more about the Bivee Project? Sign up to our quarterly newlsetter or just contact us. Bivee Information: c/o Cristina Cristalli Research for Innovation Director Loccioni Group Italy Direct: +39 0731 816280 Email: [email protected] Website: www.bivee.eu Telemetry Associates Ltd Consultants in Telemetry Applications Project Coordinator: Massimo Canducci Innovation Director Engineering Ingegneria Informatica S.p.A. via Orvieto, 19 10149 Turin Italy Mobile: +39 335 7813509 Email: [email protected] ENTERPRISE INNOVATION: A MUST TO COMPETE! European industry, particularly the manufacturing industry, needs a boost in order to compete with the challenge presented by the globalised markets. Continuous production improvement and innovation need to become a ‘natural’ attitude of European enterprises. EU industrial system is characterized by a large majority of SMEs, to innovate and compete they need to rally in business ecosystems and operate as networked, virtual enterprises. Rallying the forces is a must when SMEs address innovation, since individually they lack the necessary critical mass. The BIVEE – Business Innovation in Virtual Enterprise Environments – Project proposes an integrated Software Environment aimed at promoting and supporting production improvement and enterprise innovation for networked SMEs and virtual enterprises. The BIVEE Environment includes advanced methods for boosting creativity and innovation with an open approach, for supporting their lean implementation, for monitoring the concrete outcomes, managing the innovation ventures in a collaborative networked industrial setting, for creating shared knowledge repositories, leveraging on the collective intelligence of the communities. Tools being developed by BIVEE will model the existing environment, create a playground where ideas creation is encouraged, nurtured, and validated, providing also a testing ground to prove new ideas. REAL WORLD VIRTUAL WORLD REAL WORLD PRODUCT ION SPA CE INNOVA T ION SPA CE NEW PRODUCT ION SPA CE BIVEE is a member of the Future Internet Enterprise Systems (FInES) Cluster � BIVEE is a partly funded EU project bringing 10 organisations from 6 countries working together for 3 years to enable and manage innovation in industry Design by Telemetry Associates Ltd. as part of the deliverables for WP8 of the BIVEE Project © Telemetry Associates Limited and BIVEE Partners INNOVATIVE SOLUTIONS INNOVATION IMPLEMENTATION � OPTIMISATION � MONITOR & ASSESS MONITOR & ASSESS � SOLID SCIENTIFIC BACKGROUND INNOVATING THE WAY WE MANAGE INNOVATION To manage innovation and production improvement, BIVEE proposes the concepts of two virtual spaces: the Value Production Space and the Business Innovation Space, where SMEs come together and cooperate in value production and networked open innovation, respectively. Innovation is supported by the Shared Semantic Whiteboard that allows for remote creative cooperation, both synchronous and asynchronous, with a continuous flow and exchange of ideas, comments, suggestions. The Innovation Observatory gathers and organises new ideas and achievements coming from the most renown international academic and industrial research centres. All the relevant knowledge is semantically enriched and organised in the Production and Innovation Knowledge Repository. Both spaces, production and innovation, are constantly monitored by using a semantically enriched system of Key Performance Indicators. FRONT END PRODUCTION ENGINEERS & MANAGERS CONTROL PRODUCTION & LOGISTICS FRONT END PRODUCTION SPACE THE TECHNICAL ARCHITECTURE OF BIVEE MIDDLE-TIER INTERIM PROCESS MISSION CONTROL ROOM The Technical Architecture of BIVEE is organised in four main subsystems, conceived to serve the two tightly interwoven virtual spaces: Value Production and Business Innovation spaces, that shape the BIVEE framework. PRODUCTION MAP BUILDING & MGMT • Mission Control Room. This system supports the SMEs in the continuous improvement of a distributed, networked production reality to guarantee the effective achievement of the goals, and to identify opportunities of improvement. PRODUCTION DATA INTEGRATION & MGMT • Virtual Innovation Factory. This system provides the services aimed at promoting networked innovation for SMEs, fostering a collaborative, open innovation approach, supporting the sharing of creative ideas, feasibility studies, prototyping experiences, and engineering, with a continuous monitoring of achieved results and resource consumption. Innovation management is traditionally based on an empirical background, BIVEE proposes a systematic approach based on a solid scientific background. From Business Science to Enterprise Architecture Frameworks (such as SCOR and VRM), from social network theory to cooperative systems, from Measurement Theory and performance management to computational semantics and ontologies, BIVEE achieved an unprecedented systematic study on the foundation of collaborative open innovation that drove the development of the proposed Business Innovation Reference Framework (BIRF). The Virtual Innovation Factory is based on BIRF and its � innovation waves: Creativity – where BIVEE Environment promotes and supports new ideas and creative thinking Feasibility – where new ideas are preliminarily confronted with market, economic, and technical challenges PRODUCTION R&D ENGINEERS & MANAGERS Prototyping – where the innovation is materialised, to prove its APPLY INNOVATIVE SYSTEMS AND METHODS technical and concrete viability Engineering – where the achieved prototype is transformed into an INNOVATION SPACE industrial artefact, and operational/production plans are defined. VIRTUAL INNOVATION FACTORY INNOVATION MAP BUILDING & MGMT REAL WORLD MANUFACTURING DATA BACK END INNOVATION MGMT SYSTEM KNOWLEDGE & MODELS META REPOSITORY AGGREGATION / INTEGRATION AGGREGATION / INTEGRATION INNOVATIVE MANUFACTURING METHODS & IDEAS REAL WORLD REAL WORLD VIRTUAL WORLD INNOVATION SPACE PRODUCTION SPACE � • Production and Innovation Knowledge Repository. This system operates as a central hub that guarantees a continuous cross-flow of information and knowledge, within and across the two spaces, but also with the external world. Semantic annotation and indexing, semantic similarity reasoning, ontology management, and Key Performance Indicators management, are among the key offered services. • Real World Data and Service Management. This platform connects and integrates the real world production and innovation data in order to provide a unified, integrated view of the actual State-of-Play in the production and innovation spaces. Furthermore, it provides all the infrastructural services to administrate the BIVEE Environment. INNOVATIVE SOLUTIONS INNOVATION IMPLEMENTATION � OPTIMISATION � MONITOR & ASSESS MONITOR & ASSESS � Each wave is effectively managed, with a continuous monitoring (based on a system of semantically enriched KPIs) of the actors operating in the Business Innovation Space: a subsequent wave can be only activated after a positive outcome of a go/no-go appraisal. The Mission Control Room represents the cockpit that governs Virtual Enterprises (i.e., networked SMEs) while their members cooperate in the distributed Business Production Space (tightly connected to the innovation space). The Virtual Enterprise Modelling Framework (VEMF) sees the networked production organised in 4 Phases: Plan, Source, Build, Deliver. Here the challenge is to harmonise and continuously monitor the value production going on in a highly distributed, networked space. The Production and Innovation Knowledge Repository is based on advanced distributed knowledge representation and management methods, exploiting the Linked Open Data and Knowledge paradigm, including a suite of reference ontologies. It manages a shared knowledge pool gathering resources coming from within and outside of the Virtual Enterprise. BIVEE SOLUTIONS TESTED IN PRACTICE The BIVEE Environment has gone through extensively test, validation, and refinement phases in two radically different pilots, to also prove its flexibility and adoptability. A Pilot in the High-tech sector of robotics and automatic measuring equipment, where the Loccioni Group leads a Virtual Innovation Factory involving several partners, suppliers, customers, cooperating in extensive trialling of BIVEE solutions. A Pilot in the traditional sector of wood and furniture, where AIDIMA leads a focused trial to improve a networked production, involving low-tech SMEs that represent the main actors of the furniture industry value chain: suppliers of raw materials, external operations providers, and internal manufacturing operators.

© Copyright 2026