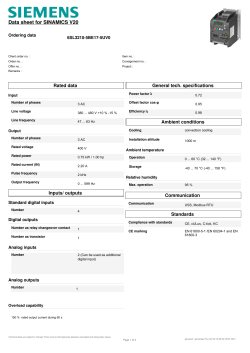

icpdf_datasheet_5 1