Document 91238

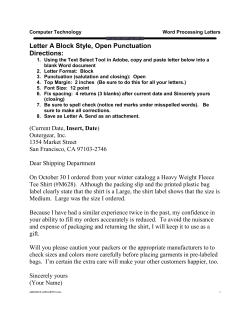

FLINN SCIENTIFIC INC. ((11 J J' [, JJ ':Jour Ja~ersource ~orscience JUpp ie» P.O. BOX 219 • BATAVIA, ILLINOIS 60510 • 800/452-1261 Vol. 93-4 CHEl\IISTRYEDITION' ©1993 Flinn Scientific, Inc. Tie-Dyeing ~Chemistry Fun Penney Sconzo Westminster School Atlanta, Georgia o The art of dyeing probably originated in India or China no later than 2500 BC. Most natural dyes came from parts of plants such as the bark, berries, flowers, leaves, and roots. Because these dyes did not have a strong attraction for the fibers being dyed, a process known as mordantinq was used to improve colorfastness. To react with acidic dyes, fibers were treated with basic or metallic mordants which might include solutions of aluminum, copper, iron, or chromium salts. Compounds formed by the dye and the mordant, called lakes, prevented the colors from washing out and made the color longer lasting. Such natural dyes became less and less important as synthetic dyes that produced brighter colors were developed. Today, Iogwood black is the only natural dye widely used. In 1856, William Henry Perkin began the synthetic organic chemical industry by accidentally discovering the purple dye, mauveine, when he tried to produce quinine from aniline. The synthetic dyes were known as coal tar dyes because the six-membered ring structures of carbon atoms were all derived from coal tar. Congo Red was the first dye discovered with so great an affinity for cellulose that a mordant was not required. o About 100 years after Perkin's first discovery, fiber-reactive dyes capable of forming covalent linkages with the fiber were discovered. A fiber-reactive dye is washfast. During dyeing, dye molecules must diffuse from the aqueous solution and into the fibers. Fibers such as cotton absorb water readily and are said to be hydrophilic, while fibers such as polyester absorb water with difficulty and are described as hydrophobic. Dyeability is influenced if a fiber can somehow carry an ionic charge and better interact with oppositely charged colored ions. To dye cellulose, a reactive dye must combine with the hydroxyl groups in the fiber. Tie dyeing is one of the oldest methods of printing designs on fabrics. Typically, parts of the fabric are bunched together in a design and knotted or tied together with string. Tied sections are protected from absorbing the dye and patterns are created. Related Chemical Concepts: Dyes, chrornophores, affinity (hydrophobic/hydrophilic). covalent bonding vs. adsorbtion, electrolyte concentration, equilibrium, kinetics, reaction rates (temperature effects, concentration effects), pH Materials Needed and Preparation Instructions • T-shirts, 100% cotton, PFD (prepared for dyeing) If you buy T-shirts that are not prepared for dyeing, they must be pre-washed in hot water with 2 tablespoons of a mild detergent like Joy®, Dawn", Ivory", etc. Do not use a detergent with phosphates or chlorines. Dry shirts on the hot cycle to remove spinning lubricants or other surface additives. • Sodium carbonate activator solution For a class of 30 students you will need approximately 8 liters of sodium carbonate activator solution. To prepare this solution, mix 250 grams of sodium carbonate anhydrous into 8 liters of distilled water and stir. • Urea solution For a class' of 30 students you will need approximately 8 liters of Urea solution. To prepare this solution, mix 650 grams of urea into 8 liters of water and stir. This solution can be stored if it is not mixed with the reactive dye. Urea increases the solubility of the heavy shades of reactive dyes. • Reactive Dyes Place a small amount of cold water in a beaker and add 4 to 6 teaspoons (12-18 grams) of the reactive dye you have selected. Mix until lumps are removed and all dye is moistened. Add urea solution (as described above) to make a total of one liter of dye solution. The amount of reactive dye is not specific as it depends on how strong you want the colors to be. Colors like yellow will need more dye. Remember some of the dye will wash out when the T-shirt is washed in hot water, so make the color darker than you want as an end product Each student will require about one cup of dye solution. For a class of 30 students, prepare a total of 2 liters <5freac- . tive dye solution for each color you want to use. Reactive dyes should be stored at room temperature. If kept dry, reactive dyes have a shelf life of two years. • Plastic bucket • Plastic drop cloth (Continued on page 2) VoL93-4 CHEMISTRY EDITION TieDyeing-Continued etc. This makes a great lab to do before the Christmas holidays. Students can make personalized gifts that are affordable. Use this activity as a fund raiser for the science club at your school. • Rubber bands! size 33 (3 1I2"L x 1/8"W) .Jumbo, Beral-type pipets, 15 ml bulb capacity . • Beakers, 1000 ml • Oven racks or sturdy plastic coat hangers interlocked between slats of wood • Rubber gloves • Ziplocksbags or small trash bags • Newspaper Procedure: 1. Fill the plastic bucket with 8 liters of sodium carbonate activator solution. Soak the T-shirts in the sodium carbonate activator solution for a minimum of 20 minutes. The ionization of cellulose increases with increasing alkalinity of the solution and above pH 8 there is an adequate number of ionized hydroxyl groups in the fiber for most dyeing purposes. Soaking the T-shirts for 2 hours will maximize the number of possible bonding sites. After the T-shirt has soaked, wring the T-shirt out over the plastic bucket. The sodium carbonate activator solution is very basic so be sure to wear rubber gloves when placing shirts in the solution and when the shirt is wrung out at the end of the activation period. Figure 2 Hint This should be' done in an area separate from the dyeing area to prevent shirts frompickingup dye by mistake. 3. Dyeing can be done on oven racks placed over sinks or on racks with newspaper underneath to absorb' excess dye. After a shirt is placed on a clean rack, dyes can be applied using jumbo Beral-type pipets. Apply the dye to one side of the shirt by slowly squirting the reactive dye solution onto each section of the shirt. A beautiful design can be made by dyeing each section of the shirt a .different color. Once you are done dyeing one side of the shirt, turn the shirt over and repeat the dyeing process. Shirts should drain for 15 minutes if possible. Students tend to use a lot of dye and there is a lot of dripping so be prepared. Hint: Fewer beakers of dye and more pipets work best. Too many beakers take too long to clean up and reorganize between classes. Shirts can pick up some dye by mistake, but students will be applying so much dye that it probably will not matter. Clean work areas will minimize problems. 2. Shirts are now ready to fold and tie. A spiral pattern is created by laying the shirt flat on a surface protected by a clean dropcloth. The shirt is held with the thumb and fingers at the point where the center of the spiral will be located. Use a twisting motion to coil the shirt and use your other hand to bring the loose ends of the shirt into the circle (see Figure 1). Take four rubber bands and slide them around the shirt so they intersect at the center where the twist began (see Figure 2). You now have what appears to look like a "pie" cut into eight pieces. The bound shirt can be turned over and dyed on both sides. We selected this type of folding pattern because it is the easiest to do and the entire tie-dyeing process can be completed in a 50minute lab period. Students also like this pattern the best. 4. Place shirts in a plastic Ziplock" bag or small trash bag and close to keep the shirt moist. Drying will prevent the reactive dyes from fully reacting. Most colors will have completely reacted after 4 hours but less reactive colors such as green and turquoise will take as long as 24 hours. Be patient. Let the dyes react completely. 5. At home, rinse the shirt in warm water (75-900F) in order to remove the unreacted dye and the sodium carbonate activator. Change the water and continue to rinse. Repeat until the water remains clear and the shirt does not feel slippery. Set the washing machine on the HOT water setting and wash as many as 10 shirts at one time in 2 tablespoons of the pre-wash, such as Joy® or Dawn" dishsoap. Dry shirts on the hottest dryer setting. The reactive dye is washfast so it is now safe to wash with other clothes using normal detergents. The reactive center on the dyes is a dichloro-triazinyl group so do not use bleaches on the shirt. 6. Now be creative! Try other patterns for folding. Dye labcoats, socks, tennis shoes, Safety Precautions: Students should wear old clothes and shoes. Reactive dyes are "wash fast." Once the reactive dye makes contact with clothes it will not wash out. Do not let the students get sloppy. Students should not squirt each other with filled pipets of reactive dye solution. Students should wear appropriate protective clothing, e.g., chemical splash goggles, disposable plastic gloves and chemicalresistant aprons. Hands may become stained from the reactive dye. It is not easily washed off and will take about two days for the dye to wear off your hands, Sodium carbonate activator solution is very basic. Be sure to wear rubber or plastic gloves when placing the T-shirts in solution and when the shirt is wrung out at the end of the activation period. Disposal: All of the chemical solutions and reactive dyes may be disposed of according to Flinn Suggested Disposal Method #26b. Consult your current Flinn Chemical Catalog/ Reference Manual. Literature Cited: American Association of Textile Chemists and Colorists (MTCC). Dyeing Primer. A series of short papers on the Fundamentals of Dyeing. P.O. Box 12215, Research Triangle Park, NC 27709. Vickerstaff, T. "Theoretical Principles of Dyeing with Reactive Dyes." Procion Dyestuffin Textile Dyeing, 1962, pp. 17-40. Special thanks to Gerald Blackstone, Eastchester High School, Eastchester, NY and Elenore Grow, Horizon High School, Brighton, CO for showing me how to tie-dye. Ordering information for Flinn's TieDyeing-Chemistry Fun Kit is listed on page 7 of this Flinn Fax. Individual tiedyeing supplies may be found below. AP8701Z Pipets, Jumbo, 15 ml capacity, AP8702Z Urea, 650 g Beral-type pkgJ120 carbonate, $ 9.50 8.45 AP8703Z Sodium AP8704Z Reactive Dye, Yellow, 45 grams 250 g 8.50 5.40 AP8705Z Reactive Dye, Red, 45 grams 8.25 AP8706Z Reactive Dye, Blue, 45 grams 10.10 AP8707Z Reactive Dye, Green, 45 grams 11.25

© Copyright 2026