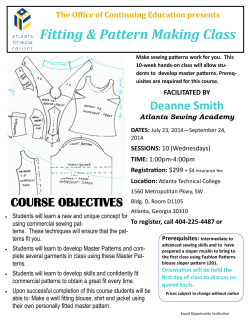

Document 96820