the flier - BVR Machine Repair & Rebuilding

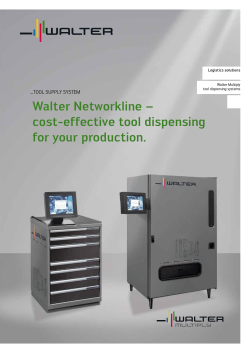

BVR Machine Repair & Rebuilding, Inc. A completed Helitronic Power machine ready to ship to a happy BVR customer A “good as new” machine for less than ½ the cost of a new machine!? A complete overhaul at BVR Machine will make your WALTER Helitronic Power function like new and run reliably for up to 10 years afterward. Because a BVR overhaul is much more comprehensive than a repair or even a rebuild: Making your machine like new Outstanding benefits ■■ Grind higher quality, more profitable tools due to improved machine function and alignment ■■ Higher productivity and faster deliveries thanks to: □□ Shorter set-ups (less “dialing in”) ■■ All linear and rotary axis components replaced □□ Less tweaking during production runs ■■ All motors and motor cables replaced (eliminating many problems that follow a typical rebuild) □□ Higher uptime ■■ All drives rebuilt to original factory specs ■■ Grinding spindle and belt replaced, plus air purge installed if not on machine ■■ All way covers replaced □□ No need to retrain operators ■■ Lower maintenance costs and fewer headaches ■■ Happier operators and lower turnover ■■ No need to purchase different wheel adapters or work holding ■■ Probe replaced Over for more ■■ Glass scales replaced, if applicable ■■ Critical wiring replaced (e.g. junction box main cable, probe body, Festo block cable, etc.) ■■ Central lube system overhauled and pump replaced ■■ Festo block replaced and pneumatic gages, lines, and fittings replaced as needed ■■ Windows replaced ■■ New paint on interior and exterior More! Call for details Phone: 540-623-9200 www.bvrmachine.com New! Can’t wait? Trade it in! An overhaul takes 10-12 weeks, so most shops schedule the work during a slow period or while rearranging their production floor. If you can’t wait, consider trading your WALTER for an overhauled machine from our stock. This will cut your downtime to a two-day switchover. We can even help install the machine and prepare the old one for removal. Supercharge the control? BVR can supercharge the HMC 400 control with 733 MHz boards that shorten the calculation time. An HMC 500 control can be upgraded to Windows XP to run Tool Studio software. But even if you don’t upgrade the control, we’ll replace the operator panel with a larger model featuring raised buttons that’s better than the original! BVR completely strips your machine and overhauls virtually everything. Above left, a C-axis workhead starts the overhaul process on a bench, while to the right, new cables are being pulled through a newly painted water cabinet Why BVR? ■■BVR is owned and operated by Rick Brown, whose 40 year career in grinding included a stint as WALTER’s North American service manager. If it’s a WALTER grinder, Rick has probably run it, sold it, and serviced it. ■■ BVR employs outstanding sub-contractors like Dan Liggett, a former WALTER field service tech, instructor, regional service manager, and control specialist, plus other former WALTER technicians who built machines in Fredericksburg. ■■ We perform a 40 hour run-in of the rotary axes, a 24 hour run-in of the entire machine, and we guarantee our work for 6 months. BVR Machine Repair & Rebuilding, Inc. 4905 Commerce Dr. Fredericksburg, VA 22408 Phone: 540-623-9200 [email protected] www.bvrmachine.com In addition to extensive testing, we grind several ballnose & corner radius endmills to ensure your machine will delight you from day one An overhauled electrical cabinet. Contrast this photo with your memory of the service hassles you’ve had lately with your old machine. What a difference! Call now! Schedule your overhaul for 2015 & enjoy 15% off the cost of an XP upgrade Quality Communication Integrity

© Copyright 2026