Military Off-the-Road Tires F2000IS002 Horst W. Stumpf , G. H. Hohl

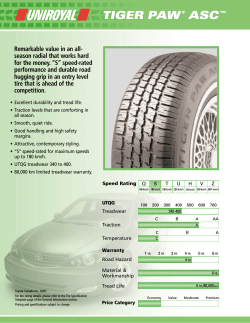

F2000IS002 Seoul 2000 FISITA World Automotive Congress June 12 -15, 2000 Seoul, Korea Military Off-the-Road Tires Horst W. Stumpf1,2, G. H. Hohl2,3 Technikum Joanneum GmbH, Austria1 Austrian Society of Automotive Engineering2 Austrian Federal Army3 ABSTRACT During the last years more military tasks have been transferred from tracked vehicles to wheeled armoured vehicles. Studies show that in most cases off-road mobility can be obtained by wheeled vehicles. It is a disadvantage of conventional pneumatic tires that they are not serviceable after a puncture. An off-road vehicle requires modern radial tires with cross-country profile, which must be able to convert the output of the vehicles engine into tractive effort on the ground. In military operations various types of tired vehicles are expected to operate over a great variety of surfaces in cross-country transport. Reliability is of particular importance. KEYWORDS: Tire, Tire Testing, Off-the Road Tire INTRODUCTION TIRE CONSTRUCTION TYPE • During the last years more military tasks have been transferred from tracked vehicles to wheeled armoured vehicles. Studies show that in most cases off-road mobility can be obtained by wheeled vehicles. But one cannot deny that a certain amount of hesitation regarding the suitability of pneumatic tired vehicles lies in the vulnerability of the tires, as they are very often exposed to the effects of enemy attack. Apart from direct hits by infantry weapons, artillery shrapnel often puts tires out of action and immobilizes the vehicle. It is a disadvantage of conventional pneumatic tires that they are not serviceable after a puncture. In many cases there is not enough time for mounting the spare wheel. These considerations require tires with emergency capabilities after puncture which offer complete safety after burst and which can be run flat for considerable distances at relatively high speeds. A vehicle provided with such an emergency running system, should be able to continue its mission on and off the road without essential decrease of its basic functions such as load carrying capacity, transmission of torque, directional and cornering stability, ride comfort, steerability acceleration and maximum speed [1]. An off-road vehicle requires modern radial tires with cross country profile, which must be able to convert the output of the vehicles engine into tractive effort on the ground as shown in Figure 1[2]. All off-highway operations do not need the same degree of traction. As a result, separate tread designs are used for different degrees of tractive effort. • • • In the construction field, as typified by dam, waterway and highway projects which require movement of large quantities of earth and rock. In this type of service, speeds as high as 40 to 80 km/h, length of haul to 16 km, and size as a means of transport of loads and equipment to 75 m3 capacity, are generally expected [3]. In the logging, mining and petroleum industries - heavier units such as mobile cranes and self-contained pumps and power plants, are used. This demands tire types with high flotation characteristics and load-carrying capacities. In military operations various types of tired vehicles are expected to operate over a great variety of surfaces in cross-country transport. Reliability is of particular importance. In general transportation into newly developed areas without adequate highways or railways - such vehicles must have flotation and mobility capability under heavy loads, without the need for extensive preparation and maintenance of roads or tracks. TIRE SIZES AND TYPES The growth of off-road operations has brought about a great diversification in tires to meet all service requirements. Tires have become larger both in cross-section and in rim diameter. Larger tires permit higher loads per tire without sacrificing flotation. With the same tire loadings, inflation pressures on the wide-base tire can be reduced. The wider cross-section gives improved traction and flotation and the lower unit ground pressure can improve the resistance to damage from stones and other objects. The wide base principle can be extended into low section-height tires. The low section-height shape makes possible a wider cross-section for improved flotation without increasing overall diameter or tire weight, as would have been necessary if conventional tire shapes had been maintained as shown in Figure 2. Radial ply Bias ply Figure 1 - Tire construction type 1 j − K H = (A ⋅ c − Fz ⋅ tan Φ )⋅ 1 − e j ... Shear displacement K (4) ... Soil deformation modulus H ... Thrust For a rotating tire or track Janosi and Hanamoto proposed a modification which accounts for the changing soil deformation along the contact length: Eq (5). L K − s⋅ K H = A ⋅ c + FZ ⋅ tan Φ ⋅ 1 + ⋅e − 1 s ⋅ L L . .. Tire contact length (5) ( ) s ... Overall wheel slip The definition of the mechanical soil parameters took place in a natural soil bin on sandy loam. The test run was made on tillaged soil. Figure 3 shows a typical example for a diagram in which the shear strength is plotted versus shear velocity. An increase of shear velocity entails an improvement of shear strength, which depends on the cohesion c and the angle of internal friction Φ. M = Distance between centers Figure 2 - Tire and rim measurements LONGITUDINAL AND LATERAL FORCES The slip definition used for military engineering is eqivalent to the definition in automotive engineering, since the tractive properties are of main interest [4]. Consequently there are two different slip definitions for the propelled and the braked wheel: Eq (1) and Eq (2). v − va sT = th v th v th ... Theoretical driving speed τmax (1) 0 < vs < 1,2 m/s Figure 3 - Influence of shear velocity on shear strength [8] Hidden line calculated v a ... Actual driving speed v − va s B = th (2) va This slip definition is useful when high positive and negative slip values are obtained in a test run and have to be presented in one diagram. A disadvantage of the definition is the unsteadiness at zero slip and the neglect of steering movements of the gauge wheel [5]. Many equations and methods were established for traction prediction more than twenty five years ago [6]. Because the soil used in this investigation had significant levels of cohesion and angle of shearing resistance, the main approach used was based on Micklethwaite's equation as modified by Janosi and Hanamoto for a driven wheel or track: Eq (3) [7]. H max = A ⋅ c + FZ ⋅ tan Φ In consideration of the shear velocity vs the Mohr-Coulomb equation Eq (6) τ max = c + σ ⋅ tan Φ τ max ... Area of tire and soil contact c ... Soil cohesion FZ ... Tire load (6) [c, σ , τ] ... N / mm is put in concrete terms for sandy loam, before passage Eq (7), (7) τ max = 0,009 + 0,04 ⋅ v s + σ ⋅ tan 29° and after passage Eq (8): (8) τ max = 0,016 + 0,026 ⋅ v s + σ ⋅ tan 32° Terrain vehicle mobility is strongly affected by the performance of the tires [9]. Here the influence of several tire parameters have already been investigated in a number of field and laboratory tests and by the use of simulation models. Most of the calculation models do not take effects of the tread profile into account. One of the earlier methods for predicting the motion resistance of a rigid wheel is that proposed by Bekker [10]. It can be seen from Eq (9) that to reduce the compaction resistance RC, it seems more effective to increase the wheel diameter D than the wheel width b. 2 H max ... Maximum thrust A ... Shear strength (3) Φ ... Angle of internal resistance Janosi and Hanamoto proposed to describe the asymptotic curves of shearing versus soil deformation: Eq (4). 2 2n+ 2 1 RC = (3 − n ) 2n + 2 2 n +1 ⋅ (n + 1) 1 ⋅ b 2 n +1 1 K 2 n +1 ⋅ C + K Φ b However, in this simulation the tread design was still neglected. The effect of the tread profile was replaced by a pure surface function between tire and soil as shown in Figure 4 [11]. 3F 2 n +1 ⋅ Z D RC = Motion resistance due to terrain compaction (9) D = Diameter of tire = Width of tire b K C = Cohesive modulus of terrain deformation K Φ = Frictional modulus of terrain deformation FZ = Normal load n = Exponent of terrain deformation Terrain vehicle mobility is not only a military problem but is also important for earth-moving and farming process. For wheeled vehicles the tire as interfacing element of vehicle and ground takes a strong effect on off-road mobility. The effect of different tire parameters have been investigated in a number of field and laboratory tests. The relationship between the total tractive force and the slip when part of the tire tread sliding on the ground is expressed by Eq (10). λ ⋅ µ p ⋅ Fz − K ′ ⋅ s 2 Fx = Fxs + Fxa = µ p ⋅ Fz − (10) 2⋅ L ⋅ K ′⋅ s ( Figure 4 - Influence on deflection The material description of the soil model is based on an elasto-plastic material law: Eq (6). Soil strength varies with the rate of compaction as shown in Figure 5. ) K ′ = L ⋅ kt ⋅ λ Fx = Tractive force Fxs = Tractive force developed in thge sliding region Fxa = Tractive force developed in the adhesion region Figure 5 – Deflection on a driven tire µ p = Peak value of coefficient of road adhesion Figure 6 shows the influence of tire pressure. λ = Longitudin al deformation of thetire tread prior to ntering the contact patch L = Contact length k t = Tangential stiffness Rolling resistance from the tire is not a vector but it is a scalar. Because rolling resistance is the conversion of mechanical energy into heat through the rolling tire: Eq (10). That relationship is very important for tire testing. dQ FR = dl P − Pout Q FR = = in (10) vR vR PR = Pin − Pout = Q Q = Loss energy Pin = Ingoing power Pout = Outgoing power v R = Rolling speed Moreover models for the simulation of tire and soil interaction have been established and improved. Recently, with the increase of computer capacity, the Finite-Element-Method (FEM) as a tool for various problems, has turned out to be suitable for the investigation of tire-soil interaction as well. Figure 6 – Influence of tire pressure TREAD PATTERN FOR OFF-ROAD TIRES Figure 7 shows different tread pattern designed for different requirements. Tires must possess the characteristics of durability, load carrying ability, speed capability and low operating temperature - to the degree which service requirements demand. High tensile cord materials must be used as reinforcement to provide sufficient strength and flexibility to the tires, and tire material should be characterized by toughness and high abrasion resistance and low heat generation during operation. 3 surface. An effective method to reduce the soil pressure is an increase of the contact area between tire and ground, for this the tire becomes wider and the flanks become softer. To characterize a tire running on a soft ground measurements a absolutely necessary. All calculations can only give a first prediction. ACKNOWLEDGMENT This paper is based upon studies that were conducted at the Automotive Engineering department of Technikum Joanneum GmbH in Austria. The work was part of a project designed to install an off-road tire measuring and FEMcalculating system. The authors acknowledge the contribution of the Austrian Federal Army. REFERENCES [1] Hohl, G. 1989. Tests of off-road tires with emergency capabilities. International Society for Terrain-Vehicle Systems, 4th European Conference, Wageningen: 100107. [2] Stumpf, H. 1989. Bereifungsmöglichkeiten für PkwGeländefahrzeuge. ÖVK Symposium: Geländefahrzeuge in Theorie und Praxis, Wien: 109-132. [3] Yong, R., Skiadas, F., Skiadas, N. 1984. Vehicle traction mechanics, Elsevier, New York: 45. [4] Haken, K. 1993. Konzeption und Anwendung eines Meßfahrzeuges zur Ermittlung von Reifenkennfeldern auf öffentlichen Straßen. Dissertation Universität Stuttgart. [5] Armbruster, K. 1991. Untersuchungen der Kräfte an schräglaufenden angetriebenen Ackerschglepperrädern. Dissertation Universität Stuttgart, VDI Fortschrittberichte, Reihe 14, Nr. 53. [6] Keen, A. 1998. Traction prediction on a sandy loam soil for a single wheel tester. Proc. of the 5th AsiaPacific Regional Conf. ISTVS, Korea: 393-400. [7] Keen, A., Craddock, S. 1997. A method for determining the tire-soil contact of a rolling tire by using the dynamic measurement of the radial and tangential tire deflection. 7th European Con. ISTVS, Italy. [8] Kutzbach, H., Schlotter, V., Barrelmayer, T. 1999. Investigations on longitudinal and lateral forces on tractor tires. Proc. 13th International Con. ISTVS, Germany: 397-404. [9] Fervers, C. 1996. Phenomena of tire-profile on different soils. Proc. 13th International Con. ISTVS, Germany: 337-344. [10] Wong, J. 1993. Theory of ground vehicles. John Wiley & Sons, New York, 2nd ed.: 150-163. [11] Aubel, T. 1996. FEM-Simulation der Wechselwirkung zwischen Reifen und nachgiebiger Fahrbahn. TÜV Bayern. Figure 7 - Off-road tread patterns (a) Representative tread pattern designed for maximum traction requirements, as in agricultural tractors, earth moving or excavation operations used. (b) Variation of this pattern in which deep grooves have been added to the traction elements to reduce rubber mass and provide lower tire operating temperatures in high-speed service. (c) Medium traction design used mainly in military operations. (d) Design which is supposed to provide extra traction in off-road operations whilst still performing satisfactorily if used part of the time on the highway. (e) Widely-rolling wheels (f) Free-rolling wheels (g) Unusual service conditions sometimes demand a special choice of tread pattern. In muskeg and deep snow operation, high flotation and traction are required and hence terra tires are used. In desert operations maximum traction is necessary but the use of an aggressive design is not always recommended because the tire may tend to dig-in, and become stuck when a no-go situation is encountered. (h) In this case, a ribbed design could be used where the lack of traction elements is offset by the large ground contact area. Snow creats problems similar to soft sand. CONCLUSIONS This review has included mainly theoretical studies of tire shape, tread pattern and structural properties of the soil or sand. The lateral force-slip angle performance is represented in consideration of inflation pressure, tire load and 4

© Copyright 2026