PlaNt ONe ON US lONdON’S RegeNt StReet ReFOReStatiON CamPaigN

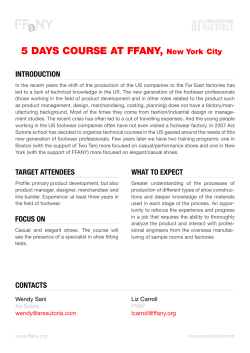

FOCUS ON Plant One on Us London’s Regent Street Reforestation Campaign At Timberland, we’re outdoor people. So we have an active interest in preserving the places where we love to recreate. Our Regent Street retail store in London turned this concept into reality. With the “Plant One on Us” campaign. A guarantee to plant one tree for every pair of boots sold at the store. Even customers who didn’t buy a pair of boots could contribute. For just $2.50 we offered to plant a tree on their behalf. (Throughout the store, you could hear staff asking customers, “Would you like a tree with that?”) We liked the idea and decided to spread the campaign to the rest of our UK retail stores. We’re making good on our guarantee by partnering with The Marston Vale Trust (www.marstonvale.org)— a charity that is converting 61 square miles of former industrial land north of London into woodlands for people and wildlife to enjoy. It is part of their 40-year vision to repair decades of industrial use by improving the landscape and environment. What was the result of the initial campaign? In 2006, our UK customers helped Timberland and the organization plant 20,000 trees. With results like this, you can bet that, in 2007, we’ll roll this initiative out globally. We believe it’s one way to allow our consumers to make purchase decisions that create positive environmental transformation. Environmental Stewardship progress report: environmental stewardship Goals for 2006resultsscore Carbon Neutral by 2010 We expanded the scope of our 2006 greenhouse gas inventory, but failed to have a third party verify it. Our 400kW solar array went into operation, reducing our California carbon emissions by approximately 40%. A carbon-neutral strategy was developed that outlines the company’s plan for reducing and offsetting its emissions for all its facilities and owned operations by 2010. Environmental Assessments Our environmental code was expanded to measure resource consumption and waste water recycling this year. Code of Conduct Specialists received in-depth training in all areas of environmental assessment, with a high level of concentration in waste water treatment systems. Timberland was also able to engage in a more in-depth evaluation at leather tanneries with a new, cross-brand assessment launched by the Leather Working Group. Improve Environmental Performance of Products After a 2005 program interruption, our water-based adhesive program rebounded with the creation of a standard for adhesive application. At the same time, we grew the use of recycled content in our product line by almost 80% and increased our consumption of organic cotton by 366,000 pounds. Our new Green Index™ rating system was launched to guide material and process selections towards earth-conscious choices. Develop Systems Procurement and Waste Management Our forest product procurement working group worked with Forest Ethics to establish a Forest Product Procurement policy and baseline. Our finance and procurement teams led early efforts to reduce paper and virgin pulp consumption through wireless billing and by switching to a higher recycled-content paper stock. Our corporate collateral, annual reports and packaging are now all made from 100% postconsumer recycled fiber. Environmental criteria are now specified in all of our procurement RFPs. Key: no improvement making progress achieved objective Confirming Our Commitment to the Outdoors We’re outdoor people. We make boots and gear and our environmental stewardship program, we’re committed clothes for your journey. We equip you to make your to doing our part to address these challenges. difference. So, we had better make sure the trail is there to hike. The river to traverse. The landscape to inspire. Because of this passion for the outdoors, we believe that doing our best to “Make it better” for our planet is at the core of our business. Unfortunately, some of today’s biggest ecological challenges have been linked to our Fortunately, we are not in it alone. We’re leveraging our partnerships with NGOs, other brands and professional service companies. And we’re working with our supply chain to demonstrate environmental leadership and reduce our impact as a global brand. industry—from global warming to deforestation. Through 2006 CSR report 35 Our Efforts to Cool the Rate of Global Warming Global warming is impacting the health of our ecosystems. We contribute to the problem by using energy that produces carbon emissions. To be a part of the solution, we pledge to be carbon neutral in Timberland-owned and operated facilities by 2010. Our Plan How are we going to achieve this in such a short time frame? Here’s our plan . . . our plan processexplanation STEP 1 Verify our greenhouse gas inventory with a credible third party. STEP 2 Reduce our energy demand through energy-efficiency improvements at our facilities around the world. STEP 3 Purchase clean, renewable energy from electric utilities. STEP 4 Generate our own renewable energy on-site where we can’t purchase clean energy from the electric grid. STEP 5 Purchase renewable energy credits to offset emissions and help develop local renewable energy projects. STEP 6 Use service and retail store promotional opportunities to plant trees that sequester (or absorb) carbon emissions beyond what we’ve reduced or offset as a company. While becoming carbon neutral is an important that has already planted 20,000 new saplings. The and challenging goal for us, we realize that the real expansion of earth-conscious product lines in footwear opportunity for reducing global warming is using and apparel. And promotional activities that support the marketplace to inspire consumers to make their regional conservation partners. For Earth Day 2007, difference. In Europe, Asia and the US, in-store and consumers had the option to forgo a paper shopping online programs build awareness and enable action. bag to make a donation to a local environmental A cornerstone of our commitment to accountability is an industry-first nutritional label on every one of our 100% recyclable shoe boxes. The label provides consumers organization. They could also purchase 100% recycled tote bags that featured a one-time discount for a return visit to Timberland. with detailed measures of our impact on the planet to Our love for the outdoors is matched by our passion invite their analysis and inform their choice. We also for confronting global warming with focus and a fully offer a series of service events and promotions that integrated strategy—from the source all the way to the engage consumers in environmental action. floors of Timberland® stores worldwide. Program highlights include a commitment to plant a million trees in the Horqin Desert in China through a strategic partnership with Marston Vale Park in London 36 2006 CSR report The Evolution of our Product Labeling More and more, today’s consumers want to know what kind of environmental footprint is being left by the products they buy. In 2006, Timberland began putting that information on 30 million footwear boxes: by placing a “nutritional label” on every box to educate consumers about the product. Where it was manufactured. How it was produced. And its effect on the environment. Green index MGI-4 A Nutritional Label—for Shoes Factors 4 ™ lower impact Climate Impact: 0 higher impact 4 10 Greenhouse gas emissions through production. 00 Chemicals Used: 10 Presence of hazardous substances (PVC, Chrome leather* and Solvent Adhesives). Resource Consumption: 9 10 0 Reduced by the use of recycled, organic and renewable materials. *Chrome leather present in leather based shoes For more information about the Green Index™ rating, see inside the shoe box or visit www.timberland.com/outdoorperformance green index ™ To create the label, three critical areas are highlighted. Information about the manufacturing plant. The impact of manufacturing on the climate. And the impact on the community, including such factors as the number of hours of volunteer service performed by Timberland employees to “Make it better” in the community. We’re also putting a message inside the box asking consumers to consider what kind of footprint they themselves are leaving and encouraging them to become proactive in Introducing the Next Step: The Green Index™ Rating the effort to protect our planet. The next step in this initiative is the Green Index™ Under this initiative, footwear boxes are also crafted from 100% post-consumer recycled waste fiber, using no chemical glues. Only soy-based inks are used to print the labels, which are the first of their kind in the industry. rating, which will go beyond printing corporate CSR information on a nutritional label on the shoebox to provide product-specific environmental impact information on the actual shoe. Using a scale of 0 (best) to 10 (worst), the Green Index™ rating will rate the shoe on three key environmental factors: climate impact, The First Step chemical use and resource consumption. By putting this So far, public reaction has been positive. But, as the information—good and bad—at your fingertips, we hope Chinese proverb states, “A journey of a thousand you’ll know exactly what you’re putting on your feet. The miles begins with a single step.” Well-informed CSR Green Index™ rating will be carried on a select line of pundit Joel Makeower agreed in his blog. Evaluating Greenscape shoes in 2007. Our goal is to have it on all Timberland’s nutritional label, he says, “It’s a step in the of our shoes by 2010. right direction” and “a laudable first effort,” but adds that it left him “hungry for more.” What to Expect Going Forward Unveiled in January 2007 at the Outdoor Retailer We couldn’t agree more. In fact, we see our new trade show in Utah, the Green Index™ rating helped nutritional label as just the first step. Of a conversation. Timberland win the Backpacker Editor’s Choice Green A promise of our commitment to transparency and Award for innovation in green product development. sustainability. And a challenge to our entire supply chain And industry-wide interest seems to be developing for and to other companies to “Make it better” for the world creating a common “eco label” for products. We’re we share. excited about this development and look forward to seeing where this journey leads. Let your own voice be heard! What do you think? Does this initiative affect your purchasing decisions or your understanding of Timberland’s footprint? How can it be improved? Let us know by writing to us at [email protected]. 2006 CSR report 37 Energy Greenhouse Gas Inventory Timberland-Owned Facilities As accountable corporate citizens with a genuine Timberland uses The World Resources Institute (WRI) commitment to environmental stewardship, we protocol for measuring greenhouse gas emissions. It’s a focus almost obsessively on our energy use and the widely accepted and utilized methodology for businesses contribution we make to greenhouse gases. Our like ours that voluntarily choose to report emissions. comprehensive approach encompasses a broad array WRI’s tools allow us to take electricity, gas, and oil of rigorous corporate policies. The development of bills as well as airline, car and public transit mileage, new green technologies and innovations. And most and calculate our contribution to climate change. importantly, engagement with citizens and partners Specifically, the model tells us our direct emissions all over the world. With their wisdom and collaboration, (the emissions from fossil fuels burned for power or we seek to achieve carbon neutrality by 2010. transportation) and our indirect emissions (emissions from purchased electricity.) Our inventory reports the The first step to carbon neutrality is to understand emissions from the facilities and vehicles we own and your baseline carbon emissions, or in other words, operate, as well as the emissions from air mileage. your greenhouse gas inventory. This year, Timberland worked to expand the scope of our 2006 greenhouse As you can see in the graph, our carbon emissions gas inventory by adding information about product increased across a majority of our business divisions. A transportation. The results are included in this section. deeper dive reveals that most of these increases can be attributed to improved proficiency with data collection. These results mask what otherwise would be considered significant emissions reductions. Nobody said this was going to be easy. In the Fall of 2007, we will release a report that will include third-party verification of our greenhouse gas inventory and a detailed brief on our climate change strategy. Direct and Indirect Emissions by Division19 8,341 7,328 7,052 Headquarters 5,507 2006 International Retail International Showrooms Direct Emissions Indirect Emissions Direct Emissions Indirect Emissions Direct Emissions 930 1,822 Indirect Emissions 46 1,889 211 936 97 112 16 12 123 122 363 Manufacturing 2,708 3,884 US Showrooms 151 84 91 58 89 269 US Retail 2,483 4,989 2005 2,322 Distribution Centers 91 2,271 314 2,158 360 291 586 0 353 2,000 303 4,000 2004 4,548 5,263 6,000 6,223 8,000 6,212 METRIC TONS OF CARBON 10,000 International Offices The system isn’t perfect. We still haven’t yet found an We’ve also been working to calculate the emissions adequate way to estimate the direct emissions from produced by the third parties that ship our product in leased spaces where heat is included in our lease the US and in Asia. That’s why we’ve partnered with agreements. Sometimes, we don’t have enough stores Businesses for Social Responsibility’s Clean Cargo in a single climate regime to make good assumptions. Working Group to build our 2006 inventory. 19 38 We have restated 2004 and 2005 data to include employee air travel in “indirect emissions” as opposed to “direct emissions.” 2006 CSR report Transportation Emissions: Ocean Freight who all are members of Business for Social The calculation of CO2 emissions is based on a model Responsibility (BSR). The calculation follows the developed by the Clean Cargo Working Group guidelines set forth by CCWG and is our best current (CCWG)—a group of Carrier and Shipper companies estimation of our transportation footprint. tons of carbon emissions related to product transportation20 2005 2006 Asia ➜ North America 10,3069,431 Asia ➜ Europe 6,047 6,448 Asia ➜ Rest of the World 202 483 Other Lanes (excluding Dominican Republic origin) 522 412 Total 17,077 16,774 Engagement: BSR Clean Cargo Working Group Timberland’s Global Transportation group has engaged with other members of Business for Social Responsibility (BSR) in a forum known as Clean Cargo Working Group (CCWG), in an effort to understand the greenhouse gas impact of our product transportation. CCWG promotes the use of industry-wide tools and methodologies to address the environmental and social impacts of transporting products. This group is working to capture information about CO2 emissions from vessels and intermodal transportation so that Shippers (i.e. brands) can understand their share. Once we have a base line understanding of our CO2 emissions, we plan to work with Carriers (i.e. transportation companies) engaged in the CCWG to reduce our overall greenhouse gas impact. Summary of Greenhouse Gas Inventory 2006 GREENHOUSE GAS INVENTORY: METRIC TONS OF CARBON21 30,000 Timberland-Owned Facilities 16,774 22,557 Employee Travel Product Transport: Inbound Ocean Freight 6,514 METRIC TONS OF CARBON 25,000 EMISSION TREND DATA22 25,084 26,854 29,071 20,000 15,000 10,000 5,000 0 2004 2005 2006 We made several assumptions for this calculation. It’s assumed that the CO2 emission factors calculated by the carrier apply to all the Carrier’s vessels—regardless of whether the Carrier owns the vessel or charters it. The Carrier CO2 emission factors also assume a fully utilized vessel, which rarely is achieved. We assume that the distance reported by distances.com (+2%) accurately reflects the true distance between ports. 21 This chart does not include outbound and intermodal product transport. It also does not include greenhouse gases associated with our contract factories. 22 Represents carbon emissions from Timberland-owned facilities and employee travel. 20 2006 CSR report 39 Efficiency Measures employees to drive hybrid cars. And Timberland plans In 2006, Timberland continued to work to reduce the to roll out a comprehensive program in 2007 to reward amount of energy we require to operate as a company. employees who have the smallest carbon footprint by Having installed renewable energy systems at almost all breaking their dependence on “dirty energy”. of our largest facilities, we began adding more focus to our retail stores. With more than 300 stores around the world, 20 renovations and 30 build-outs per year, stores represent one of our greatest opportunities for reducing our corporate energy demand. After incorporating green building principles and energy-efficient lighting in our design for years, last year we committed to exploring a more holistic approach to retail store constructions. We did that by using the US Green Building Council’s LEED (Leadership in Energy and Environmental Design) certification system as the basis for our new global standards for retail store design and construction. LEED buildings on average consume 30% less energy, use 30–50% less water and reduce waste costs by as much as 50–97%23. Our new store designs, which began construction in spring 2007, are intended to meet, at a minimum, the silver certification for LEED’s new pilot program for retail store construction. In addition, we continue to encourage our employees Renewable Energy Credits and Carbon Offsets In 2006, Timberland purchased Renewable Energy Credits (RECs) to power key community service projects and events. We also offset the emissions associated with mailing our 2005 Corporate Social Responsibility report to our partners. In this same spirit, all recipients of our 2006 Holiday card received a tree planted on their behalf by The Conservation Fund at the Illinois Wildlife Refuge. Reforestation In 2006, we began to focus on reforestation as a way to leverage consumer interest in global warming. This plan involved two major initiatives. In Marston Vale in the UK, an innovative consumer engagement strategy led to the planting of 20,000 trees in the first year alone. And in China, our Timberland Asia team has made a commitment to plant more than 1 million trees over a five-year period (2006–2011) in the Horqin Desert. to live these values. A $3,000 bonus encourages Renewable Energy In the last three years, four renewable energy systems (three solar arrays in New Hampshire, California and the Dominican Republic and a wind turbine in the Dominican Republic) have contributed to our current electricity utilization rate of 6.6% from clean, renewable sources. The most recent effort was the installation of a 400kW solar array at our Ontario, CA distribution center. The array provides 60% of the power for our facility—enough electricity to power 50 homes. In addition, our distribution center in Holland is powered by 100% renewable energy that is bought from the grid. And we use biodiesel fuel in a service vehicle at our corporate headquarters. In preparation for meeting our carbon neutral goal for 2010, we spent most of 2006 exploring renewable energy opportunities for our facilities—in particular, our manufacturing facility and our retail stores. Our goal for 2007 is to use this information to convert our manufacturing operations in the Dominican Republic to 100% renewable energy, and to purchase as much renewable energy off the grid as we can to power our retail stores. Renewable Energy Breakdown (in kWh) Total Timberland Energy Use 2006 37,089,047 42,540,928 Wind Power 637,317 727,429 Solar Power 3,000 518,518 Hydro Power 910,975 1,017,149 Renewable Energy From Grid 692,173 540,078 Total Renewable Energy Used 2,243,465 2,803,174 Renewable Energy as Percent of Total Energy Used 6.0% 6.6% Source: http://www.usgbc.org/ShowFile.aspx?DocumentID=1892 23 40 2005 2006 CSR report Chemical Management Chemicals are used in material and footwear production testing of a thermoplastic rubber substitute in 2006 is paving the way for the launch of PVC-free boots in 2008. to improve the performance and aesthetics of our product. Finding substitutes that meet the molding and physical Timberland is committed to eliminating the use of requirements for our industrial and full-shot boots remain chemicals linked to human or environmental harm. To that the two outstanding PVC-related issues in our footwear. end, the company is working to identify and adopt safer, In 2007, we will enlist the University of Massachusetts more environmentally conscious substitutes for common at Lowell Green Chemistry Program to develop solutions footwear components. These components include polyvinyl to complete our phase-out of PVC across the Timberland® chloride (PVC), solvent-based adhesives and chrome footwear line. leather. In addition, we want to stay informed of the latest developments regarding restricted substance lists. This Apparel desire informs our active participation in AFIRM. Analysis has revealed that only a few items in our apparel line contain enough PVC to require material PVC substitutions. Changes like the switchover of logos or Polyvinyl chloride (PVC) has long been linked to human the use of different trims were easy to make. Finding health issues. In our last CSR report, we discussed our substitutes for the inks used in our high-density (puffy) commitment to phasing PVC out of our products. Used printed graphics, however, proved to be an issue. Working in everything from drainage pipes to shopping bags, this with our regional suppliers around the globe did not plastic is also found in the inks applied to our t-shirts, identify a comprehensive solution last year, so in 2007 the linings of our luggage and the midsoles of our boots. we seek to work with a multi-brand group to stimulate the Footwear development of PVC-free ink alternatives. We voluntarily started removing PVC from our product Licensed Product several years ago. In 2006, we made significant strides For licensed product such as luggage, watches, belts and with our footwear by implementing a hard-and-fast rule hats, PVC again showed up in small areas. It was fairly that all new products developed by Timberland would simple to find alternatives for watch cases, for example. be PVC-free. While this initiative didn’t immediately Working with our luggage supplier to find alternative eliminate PVC in our carry-over product, such as the fabric backings is our largest ongoing project in 2007. midsoles in our classic boot models, the successful The reward of these efforts? In 2008, Timberland’s licensed accessories will be PVC-free. 2006 CSR report 41 Solvent-based adhesives Chrome III Solvent-based adhesives are used to glue footwear Chrome III is a mineral agent used in the processing components. They can emit volatile organic compounds of leather to impart key performance characteristics (VOCs), which, if not treated, can produce indoor and and long-term preservation. Due to the excellent outdoor air pollution. In addition, the extra adhesive performance properties given by chrome salts, chrome is considered hazardous waste and requires careful remains the most common means of tanning leather. disposal. Timberland began promoting the use of Although Chrome III does not pose a direct human safer, water-based alternatives in 2000. By the end or environmental threat in the processing of leather, of 2006, we had converted about 10 million pairs it can convert to a carcinogenic form known as of shoes—or about 1/3 of our product line—to Chrome VI under very specific circumstances, such as water-based adhesives (WBAs). incineration. Given the small but serious potential for We did not achieve our 2006 WBA targets of 14.4 million pairs, however, due to sourcing changes and costing pressures. To reinvigorate our approach, we began focusing our efforts on aggressive training internally and in our factories. Through this pollution, Timberland has been working with leather industry representatives to improve the environmental performance of tanneries that use chrome. As an organization, we are also working on initiatives to develop alternative tannages for footwear leather. comprehensive approach, we began to see immediate AFIRM improvements in WBA use. We have forecast this growth As the global apparel supply chain continues to grow to continue in 2007 and have projected increases of and reach many places in the world, it is important for 45% in stockfitting and 25% in assembly over 2006. brands to stay current on latest developments regarding We also intend to identify further areas where we can restricted substances lists. Based on this need, the reduce overall VOC (e.g., primers and cleaners) this Apparel and Footwear International RSL Management year. And we will problem solve other issues relating Working Group (AFIRM) was formed in July, 2004 with to materials that typically don’t bond with water-based the goal of bringing together product chemistry, safety, adhesives, such as oily leather. regulatory and other experts within the apparel industry to discuss emerging restricted substance topics, share 10 WATER-BASED ADHESIVES USED IN FOOTWEAR PRODUCTION24 MILLIONS OF PAIRS 8 6 8.40 are currently ten companies in AFIRM: adidas Group, C & A Buying, Gap, Inc., Hennes & Mauritz, Levi Strauss 8.42 & Co., Marks & Spencer, Nike, Nordstrom, PUMA 7.00 and Timberland. The guiding principles of AFIRM are 4 4.64 as follows: 3.40 2 0 information and experiences, and benchmark. There 1.40 2004 2005 WBA - Stockfit • Chemical product safety must be understood in the global supply chain as an integrated whole, from workplace to consumer. • Chemical product safety can only be achieved through partnership among retailers, suppliers and manufacturers. • Retailers must encourage suppliers’ and manufacturers’ self-governance of chemical product safety within their spheres. 2006 WBA - Assembly In 2006, AFIRM conducted a joint Vendor Event to train nearly 1,000 suppliers about RSL and created a joint RSL for vendors. 24 42 “Assembly” is the production of the upper portion of the shoe. “Stockfit” is the production of the midsole to the outsole. 2006 CSR report Resources Reducing the harmful impacts of manufacturing. And reducing our overall environmental footprint. These actions are high on the agenda at Timberland. Over the past few years, we have pledged to closely review how we design our products, our stores and even our packaging. We’re also being much more careful about how we select our resources and raw materials. Leather The durability of our footwear is due in large part to the quality leather we source for it. Leather is a byproduct from the meat-packing industry. Even so, it is a resourceintensive material to produce, so, unfortunately, leather contributes more to our environmental footprint than any other material we use in our footwear. Even more unfortunately, there is no winning technology that In 2007, Timberland will require all of its tanneries to switch over to this cross-brand assessment process. Assessments will be performed once per year by a third-party auditor who is qualified under LWG’s auditing criteria. The protocol will continue to be a dynamic one, updated by LWG members as needs and technology change. Scoring will also evolve over time as environmental technologies become increasingly available to tanners. We hope that, as the top level “bronze, silver and gold” scores become increasingly challenging to obtain, tanneries will be spurred toward better management techniques and new technologies. In the meantime, the bulk of the group’s efforts will be devoted to making tanners better aware of best practices and resources, empowering them to “Make it better” in their operations and their products. can produce leather in a way that can be considered Organic Cotton “earth-conscious.” In 2006, we grew our consumption of organic cotton Our opportunity with tanneries is to encourage sound management and year-over-year improvement in environmental performance. Having audited factories and suppliers for nearly 10 years now, we know that this is easier said than done. Tanneries undergo rigorous auditing by multiple brands, which creates audit fatigue and confusion over standards. Often, the by-products are reports, with little remediation and long-term planning. to 593,000 pounds (or 5.7% of our overall cotton purchase) through the sale of 100% organic cotton and organic cotton blended t-shirts, as well as specialty woven organic products including shirts, pants and some women’s wear lines. We also introduced a color palette specifically designed for organic cotton merchandise. This new palette was formulated with the help of dye suppliers (such as Clariant, Dystar and Huntsman) to use fewer chemicals, less water and less energy— Many Brands Work toward a Common Goal ultimately leading to less carbon dioxide emissions in What’s needed, obviously, is agreement on a common dyeing. The palette will also help Timberland comply set of rules. Recognizing this, in 2005 Timberland, Nike with the new organic certification standard, GOTS and UK-based BLC Leather Tech convened a cross- (Global Organic Textile Standard). brand, cross-tanner working group, called the Leather Working Group (LWG). This group now also includes top brands such as Clarks, Marks and Spencer, New Balance, adidas, Ikea and The Pentland Group. The first priority that LWG identified was to ensure that 8% PERCENTAGE OF ORGANIC COTTON PURCHASED 7% 6% 5.7% 5% 4% valuable brand and tanner resources benefited from a 3% streamlined assessment process. In 2006, the group 2% completed a final, peer-reviewed draft of a detailed 1% auditing process and launched it with tanners who had 0% 2.11% 2.11% 2004 2005 2006 participated in the working group. Tanners are scored on their environmental performance in over 300 areas, so Processing our organic cotton with the new eco dyestuffs the assessment is rigorous. Still, the promise of having a and using a scouring (vs. bleaching) process to remove single, comprehensive audit conducted each year, with knitting oils eliminates approximately 2 hours from the one standard performance grading system, has proven total dye processing time. We’re also seeking to save to be a real incentive for tannery participation. Other resources by encouraging new developments from textile incentives provided by the LWG include benchmarking machine builders, such as Thies, to increases our dye data, guidance documents and a forum for sharing houses’ ability to dye at lower liquor ratios. For a typical best practices. t-shirt that uses approximately 200 grams of fabric, the 2006 CSR report 43 carbon emission savings from these improvements is roughly 10gm per t-shirt (an average 15% reduction). In 2007, we have a new opportunity ahead of us: howies—a small but growing activewear brand based in Wales that Timberland acquired at the end of last year. Howies was founded on strong environmental Carden Welsh Award for Environmental Excellence 2006 Winner: Larry Klane principles and is incorporating renewable materials in Timberland has long struggled with what to do with Organic Exchange, we seek to grow our consumption of unmatched footwear samples used by our sales organic cotton to 6.5% in 2007. its product line at every opportunity. For example, their organic denim is dyed using natural indigo grown in the Tokushima Prefecture of Shikoku Island in Japan. With their brain trust and our continued partnership in the staff. Our distribution centers were never organized to collect and match these samples. We couldn’t even find a nonprofit organization willing to accept so many shoes of the same size. Sadly, in the past, we ended up having to dispose of well over 15,000 pairs of shoes a year in the United States alone. Wool The SmartWool® brand is the U.S. pioneer of woolbased socks, apparel and accessories. SmartWool works to establish good business practices that focus on environmental sustainability. Economic sustainability. That’s where Larry Klane comes in. Through Improvement in animal welfare. And social change. research and persistence, Larry developed a Environmental Sustainability partnership with several nonprofit organizations that SmartWool is the largest natural fiber-based brand in the allows our U.S. sales staff to mail unmatched shoes outdoor industry—roughly 90 percent of its raw materials to a central collection site. There, they are matched are natural and biodegradable. It is also the largest single by non-Timberland volunteers. branded purchaser in the world of wool from New Zealand, The main nonprofit where sustainable farming helps to maintain undeveloped involved was Soles4Souls. Soles4Souls is a relatively new organization, formally established post-Hurricane Katrina. They have since raised almost 1 lands. SmartWool’s fiber production uses 3 to 5 times less energy than synthetic fiber production. Plus, recent research supports chlorine use and chlorine-Hercosett wool processing, which SmartWool utilizes, as the most commercially viable and environmentally sensitive wool processing available. million pairs of shoes for Economic Sustainability displaced people along Everybody wants job security, and SmartWool helps to the Gulf Coast. For 2006, provide that for wool growers, as the world’s first wool Timberland committed to product manufacturer to develop seven-year sourcing donating 30,000 pieces contracts with them. Also, SmartWool has developed (15,000 pairs) of footwear accreditation certification standards for livestock samples to Soles4Souls. stewardship, environmental responsibility, and economic This project is a win, win, win. Win #1: We reduce our solid waste. Win #2: We outfit people who cannot afford footwear. Win #3: Instead of paying to dispose of the shoes, we receive a tax deduction that will more than offset the cost of shipping shoes to the nonprofit site. and social values for our growers. Animal Welfare SmartWool, along with its New Zealand partners, developed the first accreditation in the wool industry that ensures animal, environmental and social values. Their sheep are free-range and hormone free. They provide safe, effective and responsible use of medicines and supplements to ensure animal health. And SmartWool is the world’s first wool-product manufacturer to mandate that wool growers end Congratulations to Larry for truly embodying the the controversial practice of spirit of “Make it better” at Timberland. “mulesing” sheep. Eco-Effective Design “greening” practices for footwear (e.g. adding recycled or It makes sense to make something right from the start organic content) didn’t deliver the greatest environmental rather than less bad at the back-end. So why don’t returns. Fewer materials, lighter materials and a reduction corporate sustainability initiatives incorporate this thinking? in volatile organic compounds (VOCs) had a far greater Taking something that’s commercially successful and impact. Combining material reduction and cement-free side reinventing it to be environmentally responsible requires an stitch construction, without compromising performance entire mindset shift in the people who shape the business or aesthetics, proved to be tremendously difficult. Few and design the product. It’s hard. We are starting down materials were available that combined lightweight that path, where, instead of becoming waste, products and renewable or recycled materials while meeting our tough services become the raw materials for new products and durability requirements for abrasion, tensile strength, stitch services. That is the principle behind eco-effectiveness. tear and crocking. Most required heavy synthetic backers. Despite pioneering the use of water-based adhesives (WBAs) Product more than six years ago, our factories still struggle to keep The biggest and most important step in the direction of WBA chemistry at a development pace that matches our creating eco-effective product is to introduce a tool that rapid increase in new material use. Working with these allows our design and development teams to understand obstacles, we stripped as many parts from the shoe as we the environmental impact associated with their choice could (this reduced the shoe’s weight by between 10-15%), of materials. This tool, the Green Index™ rating, was employed a hand-stitch construction around the outsole tested by the Outdoor Group in 2006 as we developed (saving 50g of VOCs per pair) and used WBAs to construct the Greenscapes Collection of footwear. The objective the rest of the shoe (saving an additional 48 grams per pair). of the collection was to meet the technical performance and aesthetic requirements of the outdoor enthusiast, Our greatest challenges were ensuring that our Green while delivering a more earth-conscious product. Index™ rating was accurate and our design optimized sustainability. To do this, we had to obtain detailed Our challenge was to use this new, objective rating material content from our factory and from our suppliers. system to influence product design and development. We It turned out to be easier to get performance data than also had to do it within a typical six-month design cycle, chemical component descriptions of our materials. using only commercially available materials. The design In an effort to streamline this data collection (which, team hoped to achieve a rating that was at least 50% interestingly, is the biggest obstacle for other brands better than the rating for our typical product. as well), we spent six months developing an improved Application of the Green Index™ rating system taught us something we didn’t expect—namely that common factory communication process plan that we’re now applying across all new Green Index™ rated lines. Materials Used in our Product Line The following chart shows the percentage of Timberland® products25 that use one or more of the following types of materials: 25 Category Explanationpercentage Natural / Renewable Materials Harvested materials that are readily available, grow rapidly and don’t require lots of chemicals to produce. 3.76% Recycled Content Materials that contain ingredients from other products. Postindustrial material uses scrap from the manufacturing process. Post-consumer material is recovered after use by consumers. 79.50% Recyclable Materials These materials can be recycled through municipal or private programs. 75.64% Reduced Impact Materials Versions of materials that use less energy, resources and chemicals, thus saving natural resources. 6.53% Recycled Packing Materials This includes shoe stuffers, box stuffers, box tissue and separators made from recycled materials. 77.46% There were a total of 6,322 products in the survey that covered Fall 07, Fall Holiday 07 and Spring 08 product lines. 2006 CSR report 45 SmartWool® fabric lining made from sustainable, biodegradable merino wool Organically tanned, premium full-grain leather and fast-growing hemp. Vibram® EcoStep® outsole made with 30% recycled rubber Mountain Sneaker Low Hemp The Mountain sneaker is part of our Greenscapes Collection—a technical, casual footwear and apparel collection which utilizes earth-conscious materials and construction methods without sacrificing the style and function demanded by the outdoor consumer. These shoes contain: • Green Index™ Rating of 3.5: The sneaker features a Green Index™ (GI) rating for the climate, chemical and resource impact created from raw material extraction through finished product production. • Recycled PET materials: Used for more than 10 years in fleece, recycled PET is a new fiber to footwear. This fiber comes from post-consumer plastic bottles and is incorporated in the linings and laces of the sneaker. • Rapidly renewable fibers: Hemp is an extremely desirable fiber from an environmental standpoint because it grows rapidly while requiring minimal input of chemicals and water. Durability and aesthetics have always plagued the use of hemp in footwear. We found a 25% hemp/75% polyester blend that allows us to gain some of the environmental benefits of hemp without sacrificing our performance or aesthetic requirements. • Reduced VOCs: Water-based adhesives and hand stitching replaces traditional solvent adhesives, thus reducing the release of harmful volatile organic compounds. Store • Where we locate our buildings is another area where we can model eco-effectiveness. Our focus now is to consider walking and biking distance, and public transit availability, so that it’s not necessary to generate extra greenhouse gas emissions by getting in a personal vehicle to visit Timberland. We’re also looking at how we can Keeping or simply cleaning exposed brickwork and raw tongue-and-groove wall claddings, to support the statement the brand wanted to make. Refinishing remnants of the banana warehouse, including steel box rolling-racks, tables and assorted metal work, then returning them to the site as display equipment repurpose the resources in the buildings we occupy to Resources and Materials meet Timberland’s fixture requirements. Plus, we’re asking Designed elements met a set of strict constraints: if everything in the building design is necessary. Sourced • locally. Made entirely out of reused or recycled materials. Energy efficient. And most importantly, recyclable into new products after Timberland has moved on. Build as little as possible: Develop methods of achieving the desired design goals with a minimum of materials. These materials were also assessed for their embodied energy values (e.g., we used a significant amount of timber as opposed to metal). In 2006, we launched Timberland Boot Company (TBC), a premium footwear and clothing brand that combines • Use certified products: Use products such as FSCapproved softwood and sheet material in furniture and framework. These materials were finished using natural waxes and oils. • Design for disassembly: All the designed elements were designed to be simply unbolted into their basic raw-material components to either recycle or biodegrade naturally. Similarly, on a large scale, all fittings can be removed from the building, leaving minimal trace on this Grade II-listed Georgian building. In other words, if Timberland Boot Company chose to leave the site, they would leave it in a significantly restored and more usable state. • Celebrate Context: Requirements for accessibility demanded the inclusion of a DDA (Disability Discrimination Act) toilet facility and a ramped floor to the centre of the store. In order to integrate the new seamlessly with the old, reclaimed London stock bricks were sourced to create the toilet enclosure and reclaimed warehouse flooring defined the ramp. the best of modern-day innovation with earlier ideals of craftsmanship. The idea is to blend the best of the old and new, wrapping it all up in a culture of community responsibility. It was decided early on that the commercial activities of the new brand would be guided by our company’s environmental ethic. We wanted to make sure that its retail spaces would use resources effectively, by physically consuming as few of them as possible. In addition, we sought a site where Timberland Boot Company could create a “home” for itself within an established community and make a positive contribution to it—for example, by using the retail space to hold community-based events and artistic displays. Our decision to choose a historic site steered the type of environmental approach we used in the design. The key emphasis became the restoration of period features using traditional craft-based methods. All materials used were either recycled/repurposed or new materials that were from certified sustainable sources or that could be recycled without downgrading their quality. Examples include: • • Applying lime paste and wax finish to existing flooring Replacing timber cladding with sourced like-for-like material David Kira, once a banana and tomato wholesaler, is now the Timberland Boot Company. As a result of these approaches, almost no building waste was generated during the project. Energy Energy use has been kept to a minimum throughout the project by following a number of different strategies: • Transport of materials to and from site was strictly controlled, and whenever possible all fixtures and fittings were pre-fabricated and shipped in parts for efficiency. • Day lighting was enhanced significantly to the rear of the store space, through the inclusion of (new) skylight to reduce artificial lighting loads. • The artificial lighting system installed can be upgraded to significantly more energy-efficient lamps in the future. 2006 CSR report 47 we will build the culture with a global program that encourages a wide variety of green office behaviors. Environmental Stewardship in our Value Chain Our assessment process has evolved to include scoring for the environmental attributes of our factories. While we have been doing this in our tanneries for several years, in 2005 we began to roll it out to other business units. What happens is this: The Timberland Code of Conduct team, trained in our environmental standards, • Flexible sun shading to the south-facing shop front reduces glare and minimizes heat gain during the summer but, once retracted, allows for heat gain during the winter months. • The heating system is basic but utilizes a boiler chosen to match the heating requirements of the store volume. It is also mated to reclaimed cast-iron radiators. Looking Forward Modeling eco-effectiveness is admittedly an unreachable goal for our company. Every time we will think we’re closer, new information, technologies and ideas will show us that there’s more work to be done. This is a good thing. An infinite goal will keep us hungry for what’s new and better—and keep us innovating—in the environmental arena. In 2006, our goal was to begin delivering the tools that will empower our product design and development teams to make product better from the start from a sustainability standpoint. The Green Index™ rating was a powerful start. Developing design criteria for our premium earth-conscious product, Earthkeepers™ collection, provided another important set of guardrails. In 2007, we will continue down the path of automating and launching the Green Index™ rating across our line. In the near future every designer and developer will be able to get environmental statistics on their product while they are developing it. In addition, we plan to publish our internal “Green Guide,” which outlines Best, Better and Good material choices and services for everyone from product designers, to printers and facility managers, so that our entire staff will be empowered to make more informed procurement decisions. Finally, we will build the culture with a global program that encourages a wide variety of green office behaviors. This expands our existing hybrid-car incentive program to acknowledge other resource conservation and community service initiatives spearheaded by employees. 48 2006 CSR report interviews factory management to make sure that human and environmental health is protected and that environmental and management best practices are encouraged. During the assessment, we search for environmental hazards such as asbestos and PCBs, look at chemical, water, waste and energy management systems, and score factories based on how far above and beyond compliance they go with their environmental measures. With each assessment, suppliers are rated on five criteria to establish an overall score reflecting their commitment to minimize their environmental footprint. For each criterion, a factory is given a score from 1-5, with one representing no accountability or tracking and five representing factories that have exceeded stated targets. Among the areas assessed are: 1. Systems: Making sure that accountability has been formalized, with effective monitoring and procedures worthy of independent certification and a proven history of effectiveness. 2. Compliance: Ensuring full awareness of all applicable regulatory requirements, with no current instances of non-compliance in all regulated areas. 3. Chemicals (footwear only): Verifying that waterbased or hot-melt adhesives are utilized in the manufacture of Timberland® footwear, as well as up to 100% use of solvent-free cleaners, primers and adhesives. 4. Energy: Establishing and tracking energy reduction goals and checking that aggressive efficiency measures are in place, with up to 100% renewable energy. 5. Waste: Implementing waste-minimization efforts that result in up to zero-waste operations (in other words, all waste streams are either recycled or re-used). Environmental Assessment Results As a footwear-first company, we focused our environmental assessment training and tracking on our tanneries and footwear factories in 2005 and 2006. The results for 2006 are shown below for these two business units. ASSESSMENT SCORE 2.5 2006 ENVIRONMENTAL ASSESSMENT (AVERAGE) Target 2.12 Actual 1.5 1.0 2.0 2.59 2.45 2.21 2.55 2.06 2.00 1.91 1.5 2.55 2.44 Footwear Tanneries 1.0 0.5 0.5 0.0 2.5 2.53 2.0 2006 ENVIRONMENTAL ASSESSMENT (BY CATEGORY) 3.0 3 3 ASSESSMENT SCORE 3.0 Footwear Tanneries BUSINESS UNITS 0.0 Systems Compliance Energy Chemicals Resources SCORING CATEGORIES While neither business unit has achieved the target goal of three, it is clear that our tanneries have outperformed our finished-goods footwear facilities. We believe these results are consistent with the on-site visits and environmental guidance that tanneries have received from Timberland personnel for several years. Training and tracking for environmental performance was expanded to the entire supply chain in 2006, and we plan to share results in our 2007 report. Looking Forward: 2007 Goals Climate change: Address our contribution to the most pressing environmental issue of our time by implementing a strategy that will reduce our energy demand and emissions. Support the development of clean, renewable energy. And grow carbonabsorbing forests for generations to enjoy. Timberland commits to the goal of carbon neutrality by 2010. Product: Continue to implement the Green Index™ rating across our product line and our industry. This will provide our product development teams with tools to design product better from the start, and it will inform consumers’ purchasing decisions around sustainability. Employees: Launch a comprehensive program, the “Make It better” initiative, which will inform and inspire our team with opportunities to reduce corporate and personal environmental footprints. Apply the lessons learned to the development of consumer-facing initiatives that encourage Timberland consumers to make it better in their communities. ➜ ➜ ➜ VOICES OF CHALLENGE question: how far should a company go to stabilize the climate? ➜ ➜ ➜ ➜ Jonathan Dorn Editor-in-Chief, Backpacker ➜ Mindy Lubber President, Ceres As far as it can go. And then a bit farther— Climate change will have huge financial implications especially if the company is rooted in the outdoor in the years to come. How businesses and investors industry. As users and protectors and beneficiaries respond to the risks and opportunities from this issue of wilderness, we bear a unique responsibility to will have an enormous rippling effect on the global do more than the other guy, to set an example for economy. For this reason, Ceres challenges companies, our culture’s interaction with nature. like Timberland, to tackle climate change head-on. Is there any other answer that is acceptable? Not Adaptive companies know that times have changed, really. But few businesses can remake themselves that the 21st century presents unparalleled challenges overnight. Backpacker faces that predicament with sustainability at their core. Companies leading right now. Mea culpa! This magazine is a carbon- in the climate arena are formulating comprehensive intensive operation. We know we must eliminate strategies that involve the measurement and reduction all those subscription cards. We must use higher of emissions causing global warming, as well as grades of recycled paper—and less paper overall. engagement of key stakeholders. Timberland is on We know we must reinvent our business to be both the right track. The company’s 2010 goal to become profitable and carbon-neutral. And we will. carbon-neutral includes critical steps to reduce energy The outdoor industry, led by companies like Keen, Teko, Patagonia and Timberland, has turned a very use, pursue efficiency gains, purchase renewables, and, when necessary, offset emissions. important corner—the corner of intentionality. We Stabilizing the climate requires board members and know what we have to do and how far we need to senior management to focus on long-term planning. go. And most of us are on board. The important We are pleased that Timberland recently added a thing now is to instill in our companies, and in sustainability committee to its Board of Directors, each other, the kind of urgency that leads to some and expect this Committee will be involved in refining measurable progress every day, every issue, every Timberland’s future climate strategy. show, every year. However, we also need companies to show strong leadership in developing meaningful climate policy solutions in Washington. Investors are calling for analysis and disclosure of the business and competitive implications of this issue—including members of Ceres and the Investor Network on Climate Risk, an alliance of investors with nearly $4 trillion of assets. This is a necessary step to move corporate America full throttle into the clean energy economy. Chris Walker US Director, The Climate Group Tim Smith Senior Vice President, Walden Asset Management Meredith Benton Associate Director of Social Research, Walden Asset Management From the leather in its boots and the wool in its socks, to the transport of its merchandise, to the clothing its customers wear, climate change has the potential to change every aspect of Timberland’s business. Given a complex, interconnected economy and a complex, interconnected natural world, all companies will be The climate impact of the retail sector and of many consumer-facing brands may not be as obvious as that of a steel mill or power station. But retailers account for a rising percentage of overall energy consumption and CO2 emissions. And as the “hidden” footprint of retailers and brands is also significant, exciting opportunities for emission reductions exist not only at the operational level but also in the supply chain and in the products and services provided. affected by climate change. And all companies will need Exploiting these opportunities will be increasingly to make changes in order to reduce their greenhouse gas important as climate change moves up the agenda emissions and address the difficulties presented. for consumers and investors. The latest research26 A leader in socially responsive investing, Walden Asset Management manages clients’ assets to achieve specific financial and social objectives. With a focus on attractive investment returns, we seek to identify, and encourage, sustainable business models. To be sustainable, a company must approach environmental, social and governance issues in a holistic manner that incorporates long-term strategic thinking. We have found that shows that climate change is likely to be “a mainstream consumer issue” by 2010. When this happens, there will be “reputational implications for many sectors not seen to be addressing the issue appropriately.” In order to prevent putting brand value at risk consumer facing retailers and leading brands will increasingly need to take a proactive stance on climate change. operating within a sustainability framework contributes to Forward-thinking companies are already taking long-term business success. Addressing climate change significant action to reduce site-based emissions. is one key example of sustainability planning. As a boot-making family business, Timberland does However, sustainability reaches beyond a company’s not seem the most likely candidate for leading direct operations, employees, and consumers, to include the corporate world in taking action on climate its entire sphere of influence. Hence, we encourage change. With a carbon footprint equal to less than Timberland and all companies to actively work toward 1% of BP’s, Timberland’s definitive contribution to sustainability wherever they have the ability to do so emission reduction may seem inconsequential— effectively. For example, we expect them to address until the company’s supply chain and consumer topics such as greenhouse gas emissions and human outreach are considered. rights when structuring supplier relationships. We expect companies to ask hard questions, listen to hard answers and have the courage to make the necessary changes. As investors, we believe taking these steps, as daunting as they may be, is essential for sustaining the long-term health of a company—and the planet. With 120,000 factory workers worldwide and distribution vehicles traveling over 25 million miles annually, Timberland’s scope for positive change is obvious. It is our belief that, regardless of a company’s size, its capacity to make a difference is infinite. We commend Timberland for its willingness to approach sustainability issues thoughtfully, to look for opportunities for constructive change, and to test innovative solutions. We encourage Timberland’s leadership, and to go even further in prioritizing sustainability goals: in its work with its supply chain, in its sourcing of leather and other materials, and in its structuring of stakeholder relationships. The question before us was: how far should a company go to stabilize the climate? The answer is simple: as far as it reasonably can. 26 The Carbon Trust: http://www.carbontrust.co.uk/Publications/publicationdetail.htm?productid=CT-2004-10 2006 CSR report 51

© Copyright 2026