Quick Splice II 5451R 25/28 kV Molded Rubber Cable Repair Splicing Kit

Quick Splice II 5451R (CN) Cable (JCN) Cable É É Accessory Splice Jacket 25/28 kV Molded Rubber Cable Repair Splicing Kit Data Sheet 1. Product Description 2. Applications The 3M 5451R Quick Splice II is a 25/28 kV class inline splice designed to serve as a cable repair for concentric neutral (CN) and jacketed concentric neutral (JCN) distribution class power cables. It is designed to replace up to 6 inches (152 mm) of damaged cable, thus eliminating the need to splice in a new section of cable with two separate splices. To make a repair splice on 25 kV and 28 kV class distribution cables: The splice is a one-piece molded design made of specially formulated, peroxide cured EPDM rubbers. Each splice is production tested on CN cable to ensure reliability. The splice is designed for use with the special CIR–Series Inline Compression Connector provided, for connecting either aluminum or copper conductors. The 5451R Quick Splice II meets the 25 kV voltage rating requirements of ANSI/IEEE Std. 404–1986. Kit Contents: For inline repair splicing of damaged cable For cable repairs up to 6 (152 mm) in length For damaged concentric neutral (CN) cable For damaged jacketed concentric neutral (JCN) cable (used with an accessory splice jacket, e.g. 3M SJ–A Series with additional 8420 Series Cold Shrink Insulator or 3M HSJ Series with additional ITCSN Series Heat Shrinkable Sleeve) For fitting cable insulation diameter sizes of 0.870 to 1.055 (22,1 to 62,8 mm) For direct burial installations For aerial installations For submerged locations 1 Molded rubber splice body 1 Connector (CIR–Series) 2 Packets of silicone grease 1 Template 1 Instruction sheet Splice Features: One-piece design, for simple installation Elongated splice body, allows for the removal of up to 6 (152 mm) of damaged cable Special 3M CIR–Series repair connector, for a one-piece connection to bridge across the gap resulting from the removal of damaged cable Production tested, partial discharge and alternating current withstand, for long term reliability Peroxide cured EPDM rubber construction, for long term elastic memory (sealing) and easy installation Computer designed, for compact size and optimal distribution of the electrical field 3. Data: Physical and Electrical Properties The 3M 5451R Quick Splice II can be used on distribution class cables with a rated operating temperature of 90C, and an emergency overload rating of 130C. Splices made with this kit are rated for 25 kV and 28 kV and meet the 25 kV rating requirements of ANSI/IEEE Std. 404–1986, “IEEE Standard for Cable Joints for Use with Extruded Dielectric Cable Rated 5000 V through 46,000 V.” The current rating of the splice meets or exceeds the current rating for the cables on which it is installed. BIL rating of the splice is 200 kV. A Special 3M CIR–A or CIR–840 Series connector is included with the splice kit. It is crimped with a standard 5/8 die or 840 die, respectively. These connectors meet the requirements of ANSI C119.4–1986, “Connectors for Use Between Aluminum or Aluminum-Copper Overhead Conductors.” A. Selection Table SPLICE KIT SELECTION TABLE Kit Number (with connector)* Cable Insulation (O.D. Range)* Conductor Size (AWG) Cable Insulation Thickness (mils) 5451R–CIR–21A 0,870 – 1.055 in. (22,1 – 26,8 mm) 2 or 1 Stranded 1 or 1/0 Solid 260 280 295 5451R–CIR–21–840 0,870 – 1.055 in. (22,1 – 26,8 mm) 2 or 1 Stranded 1 or 1/0 Solid 260 280 295 5451–CIR–1/0A 0,870 – 1.055 in. (22,1 – 26,8 mm) 1/0 Stranded 260 280 295 5451–CIR–1/0–840 0,870 – 1.055 in. (22,1 – 26,8 mm) 1/0 Stranded 260 280 295 *NOTE: CIR–A Series Connectors are sized for 5/8 crimping die; CIR–840 Series Connectors are sized for 840 crimping die. Table 1 B. Typical Dimensions Dimension A B C 18.4 in. (467 mm) 2.47 in. (63 mm) 1.16 in. (29 mm) Table 2 —2— C. Typical Physical and Electrical Properties D Ultimate Tensile Strength ASTM D 412 Insulating EPDM Rubber Physical Properties Test Method D Color D Ultimate Elongation ASTM D 412 D Ultimate Tensile Strength ASTM D 412 Typical Value* White 400 psi (2.8 MPa) 55 D 300% Modulus ASTM D 412 1800 psi (12.4 MPa) 19% 185 psi (1.28 MPa) D 300% Modulus ASTM D 412 650 psi (4.49 MPa) Electrical Properties Typical Value* D Dielectric Constant ASTM D 150 73_F (23_C) 194_F (90_C) 266_F (130_C) 2.71 2.58 2.56 D Dissipation Factor ASTM D 150 73_F (23_C) 194_F (90_C) 266_F (130_C) 0.4% 1.3% 4.7% 1177 Volts/mil (46.4 MV/m) 518 Volts/mil (20.4 MV/m) D Ultimate Elongation ASTM D 412 D UV Resistance (70 hrs. @ 20% strain) No Cracking Test Method D Volume Resistivity (3M Test Method TM 80) Typical Value* 15.4 Ohm–inch max. (40 Ohm–cm max.) * This data is not to be used for specification. Values listed are for typical properties and should not be considered minimum or maximum. 4. Specification (Open Specification) The concentric neutral (CN) and jacketed concentric neutral (JCN) cable repair splice must meet the requirements of ANSI/ IEEE Std. 404–1986 for a 25 kV rating, and must be rated by the manufacturer for use on 25 kV and 28 kV distribution systems. It must be rated for continuous operation at 90_C, with an emergency overload temperature rating of 130_C. The repair splice must be capable of replacing up to 6 inches (152 mm) of damaged CN or JCN cable. The splice shall be a one-piece, slip-on design made of molded peroxide cured EPDM rubber. It shall be rated for indoor, outdoor and direct burial applications. Engineering/Architectural 1066 Volts/mil (42.0 MV/m) 790 Volts/mil (31.1 MV/m) Physical Properties D Color No Cracking Product Splice Jacket Semi-Conductive Rubber Test Method D Ozone Resistance (70 hrs., 150 ppm @ 20% strain) Electrical Properties D 100% Modulus ASTM D 412 100 mil thick slab 225 lbs/in min. (39.4 KN/m min.) D 100% Modulus ASTM D 412 D Compression Set ASTM D 395, Method B D 20 Days @ 96% RH and 194_F (90_C) 25 mil thick slab D Die C Tear ASTM D 624 900 psi min. (6.21 MPa min.) 25% 100 mil thick slab 70 20% max. D Permanent Set (3M Test Method: 100% strain with 5 min. recovery) D Dielectric Strength ASTM D 149 25 mil thick slab D Shore A Hardness ASTM D 2240 D Permanent Set (3M Test Method TM 86A) 570% min. D Shore A Hardness ASTM D 2240 Test Method 1700 psi min. (11.7 MPa min.) Typical Value* Black 300% min. —3— (Closed Specification) Repair splicing, for up to 6 inches (152 mm) of damaged cable length, of all 25 kV and 28 kV rated concentric neutral (CN) and jacketed concentric neutral (JCN) cables sized 2 AWG through 1/0, shall be performed in accordance with the instructions provided with the 3M 5451R Series Quick Splice II Molded Rubber Cable Repair Splicing Kit. For JCN applications, the splice shall be sealed with an additional jacket installed in accordance with the instructions provided with the 3M SJ–A Series Cold Shrink Jacket Kit, plus the addition of an 8420 Series Cold Shrink Insulator to provide for additional repair length. 5. Performance Tests IEEE Std. 404–1986 25/28 kV Voltage Rating Test Requirements Design Test and Sequence Seq ence 25 kV 28 kV* Minimum Partial Discharge (Corona) Level (kV–rms @ <3 pC) 21.6 24.2 Alternating-Current 1 Minute Withstand (kV–rms) 52 58 Direct -Current 15 Minute Withstand (kV–dc) 100 112 Impulse Withstand (BIL) at 68F (20C) (kV–crest) ±150 ±168 Impulse Withstand (BIL) at 266F (130C) (kV–crest) ±150 ±168 Minimum Partial Discharge (Corona) Level (kV–rms @ <3 pC) 21.6 24.2 Cyclic Aging (kV–rms) 43 48 High Voltage Time 5 Hour Alternating-Current Withstand (kV–rms) 1 Hour Alternating-Current Withstand (kV–rms) 52 78 58 87 Short-Time Current (sec.) (ICEA P–32–382 and ANSI/IEEE C37.09–1979) 0.17 0.17 Alternating-Current 1 Minute Withstand (kV–rms) 52 58 Shielding IEEE Std. 592–1990 ANSI/NEMA CC3–1978 and ANSI C119.4–1986 Connector Thermal and Mechanical Production Test Test Requirements Production Units Tested (%) 100 Minimum Partial Discharge (Corona) Level (kV–rms @ <3 pC) 24.2 Alternating-Current 1 Minute Withstand (kV-rms) 58 * NOTE: 28 kV test requirement values are extrapolated from standard IEEE 404–1986 values. Table 3 e. Connect other end of connector and place a tape marker 1/2 (13 mm) from end of cable semi-con. 6. Installation Techniques Detailed Instructions for installing the 5451R Quick Splice II are included with each kit. The following is a brief summary of the installation steps required: a. Cut out damaged section of cable but do not exceed 6 (152 mm). b. Fold neutral wires back and prepare cable. 1/2 Cable Semi-Con Tape Marker CABLE Y f. Lubricate exposed connector and cable. Center splice body over connector, aligning its end with the tape marker. c. Install CIR Connector onto one cable. d. Lubricate connector and cable, and slide splice body onto connector until uncrimped end is exposed. Tape Marker CABLE X CABLE Y g. Join neutral wires, attaching one wire from each cable to the splice grounding eyes. CABLE X Grounding Eye Splice Body Uncrimped Connector End CABLE X É Connector —4— Grounding Eye CABLE Y Installation Techniques (continued) 8. Availability h. JCN Cables Only: Install accessory splice jacket over splice and exposed neutral wires. 3M 5451R Quick Splice II Kits are available to splice 25/28 kV CN and JCN distribution class cables. They are available in four kits, with the special CIR–Connector included, from your local authorized 3M electrical distributor. CABLE X É Accessory Splice Jacket CABLE Y 7. Maintenance Components of the 3M 5451R Quick Splice II Kit are stable under normal storage conditions. Normal stock rotation procedures are recommended. The splice can be field tested using normal field cable testing procedures (reference: ANSI/IEEE Std. 400, “Guide for Making High-Direct-Voltage Tests on Power Cable Systems in the Field).” —5— Important Notice to Purchaser: All statements, technical information and recommendations related to the Seller's products are based on information believed to be reliable, but the accuracy or completeness thereof is not guaranteed. Before utilizing the product, the user should determine the suitability of the product for its intended use. The user assumes all risks and liability whatsoever in connection with such use. Any statements or recommendations of the Seller which are not contained in the Seller's current publications shall have no force or effect unless contained in an agreement signed by an authorized officer of the Seller. The statements contained herein are made in Electrical Products Division 6801 River Place Blvd. Austin, TX 78726-9000 lieu of all warranties expressed or implied, including but not limited to the implied warranties of merchantability and fitness for a particular purpose which warranties are hereby expressly disclaimed. SELLER SHALL NOT BE LIABLE TO THE USER OR ANY OTHER PERSON UNDER ANY LEGAL THEORY, INCLUDING BUT NOT LIMITED TO NEGLIGENCE OR STRICT LIABILITY, FOR ANY INJURY OR FOR ANY DIRECT OR CONSEQUENTIAL DAMAGES SUSTAINED OR INCURRED BY REASON OF THE USE OF ANY OF THE SELLER'S PRODUCTS. Recycled paper 40% pre-consumer 10% post-consumer Litho in USA 1995 3M 80Ć6108-5074-7

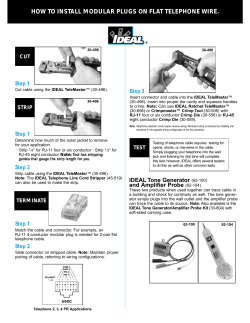

© Copyright 2026