131876 - Masonry Coatings Product Guide

masonry Resins, Polymers, Additives & Formulated Solutions Masonry Coatings Product Guide www.lubrizol.com/masonry Resins and hyperdispersants for mortarmodified Elastic waterproofing membranes. Resins for premium Roofing topcoats. Resins for concrete coatings for pool decks and waterproofing membranes. primer resins for all roofing substrates. Resins and dispersants for verical elastomeric coatings. Acrylic Resins and Polyurethane dispersions for horizontal masonry coatings. Resins and dispersants for sealers and decorative topcoats. 2 Making the world More beautiful through Innovative surface coatings 3 Horizontal Surfaces BUILD TO LAST WITH LUBRIZOL Creating solutions that deliver value for coatings manufacturers, architects, builders and building owners—that’s the mission of Lubrizol. Our advanced suite of resins, polymers, hyperdispersants and surface modifiers beautify and strengthen a diverse range of interior and exterior masonry coatings. From lasting durability to uncompromised aesthetic appeal, Lubrizol is a world leader in providing solutions for coatings, all backed by a track record of real-world results. Lubrizol ingredients not only build coating performance, they provide additional value at every step. For coatings manufacturers, our product portfolio can maximize material usage and production efficiency. For contractors and architects, our products can shorten construction schedules and reduce labor costs by simplifying application. For property owners, Lubrizol offers an array of powerful protectants to minimize the time, cost and hassle of maintaining surface appearance and functionality. Horizontal surfaces often experience the toughest wear. Lubrizol’s resins and additives improve the look and performance of coatings for stamped concrete, polished concrete and even epoxy floor systems with unique color and media dispersant technology. Roofing Lubrizol delivers added value to roof coatings with premium waterborne acrylic and polyurethane resins. We offer additives that enhance reflectivity, which lowers energy costs for building owners while offering dependable protection against weathering, dirt and ponding water damage. Mortar Modification Vertical Surfaces Suitable for concrete, block, brick, stucco, fiber cement and EIFS, Lubrizol resins and additives ensure a great appearance with excellent color development and resistance to water, efflorescence and dirt pick-up. 4 We offer an array of solutions tailored to creating high performance modifications to mortar. From cementitious membranes to adhesion-promoting additives for concrete repair, our proven solutions impart critical performance and aesthetic characteristics, including waterproofing, stress and cracking resistance, as well as adhesion promotion to improve concrete structures. 5 KEY FEATURES NMP-Free FormaldehydeFree* Carboset® 2968 Acrylic Copolymer Emulsion Yes Yes Yes Carboset® AE-960 Acrylic Emulsion Yes Yes Yes Carboset® CA-600 Acrylic Emulsion Yes Yes Yes Carboset® CA-1008A Acrylic Polyurethane Polymer Emulsion No No Yes Carboset® CA-1009 Acrylic Polyurethane Polymer Emulsion Yes Yes Yes Carboset® CR-728 Acrylic Copolymer Emulsion • Excellent hardness. • Superior water resistance. • Outstanding chemical, stain and early mar resistance. • Best industry gloss/wet look in comparison to Carboset CA-600 and Carboset CR-728. • Excellent dirt pick-up. • Superior efflorescence and alkali resistance. • Outstanding water resistance, weathering and crack bridging performance. • Good early water resistance and short dry time. Good substrate penetration. • Excellent resistance to blushing, alkaline, efflorescence. Excellent stain and chemical resistance. • Excellent exterior exposure/weathering and non-yellowing. • Excellent water resistance/low water absorption. • High elasticity before and after weathering. • Low dirt pick-up and excellent weathering durability. • Superior water resistance. • High durability against wear and weather. • UV and thermal aging resistance. • Very low water uptake and capillary absorption • Excellent water, chemical and stain resistance. • Exceptional harness, clarity and appearance. • Outstanding early mar resistance. • Better industry gloss/wet look than Carboset CA-600. Yes No Yes Carboset® CR-785 Acrylic Copolymer Latex • Cure and seal polymer for horizontal concrete. No Yes No Carboset SA-820 Styrene Acrylic Copolymer Emulsion No Yes Yes Carboset® SA-850 Acrylic Copolymer Emulsion No Yes Carboset® SA-860 Styrene Acrylic Emulsion No Carboset® X-Flex-100 Acrylic Emulsion Doresco® AC4-74 Solventborne Acrylic Polymer in Toluene • Very stable; resists deterioration and efflorescence when applied directly to highly alkaline substrates such as green concrete and hot stucco. • Outstanding long-term elasticity. • Excellent water and alkali resistance. • Excellent dirt pick-up, alkali and efflorescence resistance. • Superior crack-bridging capability and weathering performance. • Excellent resistance to chalking, fading and water penetration. • Excellent resistance to dirt pick-up, efflorescence, alkali and water. • Outstanding weathering and crack bridging performance. • Superior adhesion to cementicious substrates. • Imparts high mortar flexibility. • High flexibility at low temperatures. • Dual adhesion properties for adhesion to concrete and tile adhesives. • Good combination of toughness and flexibility for interior and exterior applications. • Provides fast solvent release and generally films that resist blocking. • Upon moderate aging, air dried applications will exhibit the same end properties as baked systems. Doresco® L91-1x Solventborne Acrylic Polymer in Xylene Permax™ 805 Vinylidene Chloride Emulsion Sancure™ 20025F Aliphatic Polyurethane Dispersion Coating VOC Capability 76 8.1 57 1.05 250 g/L VOC 55.0 2,000 max 8.5 – 1.03 0 g/L VOC Capable 42.0 41 8.3 35 – 100 g/L VOC • 48.0 5-100 8.5 0 – 50 g/L VOC • 54.0-56.0 150-800 8.0-9.0 – – 50 g/L VOC • 42.0 25 8.0 45 – 100 g/L VOC • 42.5 40 8.0 44 1.03 270 g/L • 49.0 10,000 8.3 0 1.03 0 g/L VOC Capable Yes • 55.0 100-1500 7.9-8.7 9 1.06 50 g/L VOC Yes Yes • 50.0 7,000-10, 500 8.3 21 1.06 150 g/L VOC Yes Yes Yes 60.0 250 8.5 – – – Yes Yes Yes • 45.0 8,000 – – 0.96 350 g/L • A general purpose hard acrylic that is good for concrete coatings. Yes Yes Yes • – 6,000 – – – 350 g/L • Excellent moisture vapor transmission resistance. • Superior corrosion and humidity resistance. Shelf life up to 12 months. • Recommended as a metal roof coating primer. • Can be blended with acrylics to enhance coating durability. Yes Yes Yes • 60.0 85 1.0-2.2 13.5 1.28 100 g/L VOC Yes No Yes 500 max 8.0 – – 50 g/L VOC No Yes Yes • • 48.0 • Developed to match the properties of high performance polyurethane dispersions without the use of NMP and with low VOC content. • Exceptional outdoor durability, non-yellowing, inherent UV and mildew resistance. • Excellent floor wear and water, alcohol and household cleaner resistant. • Exceptional pigment compatibility. 34.0 200 max – – – 41 g/L VOC No No Yes 45.0 1000 max 8.0 10 – 100 g/L VOC Horizontal Masonry Coatings 42.0 Roof Coatings Specific Gravity Waterborne Oil-Modified Urethane Dispersion MFFT (˚C) Sancure™ OM-945 pH Aliphatic Waterborne Urethane Polymer Viscosity cP Sancure 20041 ™ Weight Solids (% ) ® typical Physical Properties Mortar Modification Description RESINS & POLYMERS FOR MASONRY APPLICATIONS Vertical Elastomeric Coatings Product Name APEO-Free USES • • • • • • * FTC definition for formaldehyde free. Formaldehyde is not intentionally added. HYPERDISPERSANTS FOR MASONRY APPLICATIONS typical Physical Properties Product Name Pigment Type Uses Physical Form Active (% ) Solvent Solplus™ D510 Organic & Inorganic Increased pigment or silica sand loading, improved self-leveling, color separation resistance and resistance to settling. Particularly effective in epoxy flooring applications. Liquid 100 – Solplus™ D570 Inorganic Effective in dispersing higher levels of inorganic pigments and fillers in 100% solid epoxy systems. Polymer design improves viscosity stability. Particularly effective in epoxy flooring applications. Liquid 100 – Solplus™ K500 Inorganic Improvement of dispersion and stability, increased filler loading and improved wetting. Particularly effective in epoxy flooring applications. Liquid 100 – Solsperse™ 40000 Inorganic General purpose waterborne, low foam, great for TiO2 and CaCO3. Liquid 85 Water & diethanolamine (DEA) Solsperse 46000 Organic & Inorganic Dispersion of TiO2 and fillers with improved color stability. Liquid 50 Water ™ 6 7 North America Lubrizol Advanced Materials, Inc. 9911 Brecksville Road Brecksville, OH 44141 USA +1.800.380.5397 Europe Lubrizol Limited PO Box 42, Hexagon Tower Blackley, Manchester M9 8ZS United Kingdom +44 161 721 6800 Asia-Pacific Lubrizol Specialty Chemicals (Shanghai) Co., Ltd 10/F, Park Center International No. 1088 Fang Dian Road Shanghai 201204, PR China +8621-3866-0366 South America Lubrizol do Brasil Aditivos Ltda Avenida Nove de Julho, 3653 Jardim Paulista Sao Paulo – SP WHAT WE ADD MAKES THE DIFFERENCE.™ At Lubrizol, we innovate coatings solutions that help our customers balance the aesthetics, durability and functionality needs of their products for a wide array of surfaces and substrates. Our strength is in collaborating with customers to solve their toughest challenges— such as making coatings safer, enhancing production efficiency and reducing environmental impact—without compromising performance. To learn more, contact your Lubrizol representative or visit www.lubrizol.com/coatings. 01407-000 +55.11.4097.0250 Visit us at: www.lubrizol.com/masonry © The Lubrizol Corporation 2014, All Rights Reserved. 131876

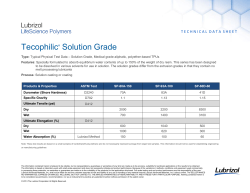

© Copyright 2026