Document 86030

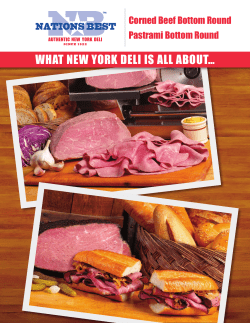

7KH*XLGHWR%HHI6DODPL 6SHFLDOO\GHYHORSHGIRU0LGGOH(DVWFOLHQWV$FFHOHUDWHGIHUPHQWDWLRQSURFHVV XVLQJLQJUHGLHQWVZLWK*G/FRQWHQWUHGXFLQJSURFHVVLQJWLPHFRQVLGHUDEO\HJ IURPZHHNVWRGD\V 7KHIROORZLQJJXLGHLVLQWHQGHGWRGLVFORVHDOOSRVVLEOHLQJUHGLHQWVZKLFKFRXOG EHXVHGWRPDNH%HHI6DODPL$FFRUGLQJWRORFDOPHDWTXDOLWLHVDQGPDFKLQHU\ %HHI6DODPL SDUNUHVXOWVDQGDFFHSWDQFHPD\YDU\ 5DZ0DWHULDOV IUR]HQEHHI, 70 – 80% vl [visual lean] IUHVKEHHI, completely lean %HHI This meat recipe may be altered according to local requirements and availability. No water or ice must be added. 3UR7LS: The fresh lean beef should not be from freshly slaughtered meat but 3-4 days matured at +2° C for best processing result. S+GHYHORSPHQWXVLQJGLIIHUHQW*G/GRVDJHOHYHOV Salami Rapido contains GdL [glucono delta-lactone] to accelerate the fermentation process. If used as recommended, 0.5% of GdL will be added to the final meat product. Refer to next page for details. $GUHVVH friedrich gewürze gmbh Marktstätte 8 D-78462 Konstanz +DQGHOVUHJLVWHU .RQVWDQ] *HVFKlIWVIKUHU 7HOHIRQ (PDLO Reinhard J. Friedrich + 49 7531 89276-0 [email protected] 7HOHID[ ,QWHUQHW +49 7531 89276-10 www. ingredients.de Nr. HR B 1548 USt-ID '( 6HDVRQLQJDQG,QJUHGLHQWV3HUNJ7RWDO6DXVDJH5HFLSH[meat + water/ice] 6DODPL5DSLGR J 6DODPL5DSLGR complete blend of spices and functional ingredients for accelerated production of salami and other dry sausage products. Reduced processing time due to added GdL which acts as a fermenting accelerator. Spice blend is especially developed to cover the undesired GdL flavour. Choose 6DODPL&ODVVLF or 6DODPL0LODQ for natural fermentation process without GdL acceleration Nitrite Curing Salt. We recommend to use nitrite curing salt concentrate to &XUH0L[. J Cure Mix 5/5 contains 5% sodium nitrite and 5% potassium nitrite. Mix 1 part Cure Mix 5/5 with 9 parts of regular salt to achieve a curing salt with 1% active cure content. 2SWLRQDO:'H[WURVH. Use to cover unwanted salt-flavour when higher salt to addition is needed to preserve freshness and yield. J Improves mouthfeel and texture. Reduces the a -value which results into w reduced micro-biological activities. J 2SWLRQDO: 0HLVWHU*OXWDIL[ premium flavour enhancer based on mono sodium glutamate [MSG]. For all food products. Eliminates unwanted salt flavour and balances flavour profile in general. Especially suitable for meat products and convenience foods. to JNJ 2SWLRQDO: *DUOLF([WUD, highly concentrated liquid garlic extract, made from fresh garlic cloves. Use to round off flavour and to cover undesired off-flavours. Long-lasting flavour retention. Garlic has anti-bacterial properties. Clean label declaration [VSLFH or JDUOLF]. 2SWLRQDO: Starter cultures, if desired &KHFNRXUZHEVLWHIRUPRUHLQIRUPDWLRQLQFOXGLQJ LQJUHGLHQWGHFODUDWLRQDQGSULFHV: http://www.ingredients.de Page 2 of 2 Recipe Beef Salami dated 01.09.2005 3URFHVVLQJ,QIRUPDWLRQ1 &DVLQJV We offer and store a wide range of FDVLQJV for cooked sausage. Fibrous casings, ready to be cooked and smoked, or moisture-proof PA-casings for smokeless sausages. Always soak sausage casings properly – minimum 30 minutes in luke warm water. The complete range with prices can be viewed online here. 0L[LQJ*ULQGLQJ For Beef Salami, best results are achieved when preparing the lean, fresh beef by grounding it through the 3 mm plate. This will ensure binding of the clean cut frozen meat parts with the ground lean meat in the bowl cutter. Photo courtesy of Kilia http://www.kilia.com Photo courtesy of CFS: http://www.cfs.com &XWWLQJ Place the frozen beef with all ingredients except for the curing salt into the bowl cutter and start chopping at low or medium speed until the desired texture is reached. At this time, add the ground lean beef and blend with the frozen beef for as long as needed to distribute the lean beef thoroughly. Finally, add the curing salt during the final rounds. 3UR7LS: Use sharp bowl cutter knifes to secure clean cut texture. )LOOLQJ Fill into pre-soaked fibrous casings [minimum 30 Minutes in luke warm water] and allow to adjust temperature for a few hours before removing into the cooler. 3UR7LS: It is important that the sausage mix is filled tightly, to ensure that no air pockets disturb the fermentation process and causing discolouration. Photo courtesy of handtmann: http://www.handtmann.de )HUPHQWLQJDQG6PRNLQJ Apply cold smoke, if desired for several hours. Keep in the cooler for 3-5 days according to diameter, until the salami is ready to be sliced or packed. Natural fermentation process requires long fermenting time. A post-smoking climate room is necessary to control both humidity and temperature during the Photo courtesy of fermentation period. This may take 2-4 weeks, depending on the sausage diameter. Fessmann: http://www.fessmann.de 3UR7LS: Measure pH value of the sausages before slicing or packing to secure that the salami is fit for consumption. Desired pH: 5.0 to 5.3 This is the Isoelectric Point or, in other words, the optimum pH value for further processing, i.e. slicing, packing or shipping. 1 This recipe was developed with the best of knowledge, and according to today’s technical standards. However, we cannot accept any responsibility for the result or lack of acceptance. Page 3 of 3 Recipe Beef Salami dated 01.09.2005

© Copyright 2026