Benefits of SOLAμ Technology in Sample Preparation

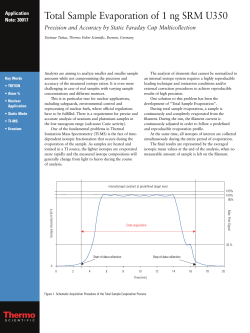

The Benefits of SOLAμ Technology in Sample Preparation Jon Bardsley and Ken Meadows Thermo Fisher Scientific, Runcorn, UK Introduction Precision M The modern bioanalytical and clinical research laboratory must provide high quality analytical results from complex biological samples in a high throughput environment while complying with strict legislation. The proprietary The micro elution produ elution formats. By solid uniform sorbe These demands are compounded by the continued drive to higher efficacy drugs and long acting formulations which continue to push the required quantification limits to lower levels. There is also the desire to take advantage of the replacement, refinement and reduction policy. The growth of bio pharmaceuticals also brings into consideration additional analytical challenges such as solvation and non-specific binding. FIGURE 3. SOLAμ formats Thermo Scientific™ SOLAμ™ plates are designed for bio-analytical and clinical research analyst’s who require cleaner, highly reproducible and robust sample extraction at very low sample and solvent volumes in high throughput workflows. SOLAμ achieves this due to the unique and innovative frit-less SPE technology. SOLAμ meets bioanalyitcal needs by providing: • A Robust low sample volume preparation platform • Reproducibility at low sample and solvent levels • Processing of low volume samples • Sample enrichment • Mitigates against solvation and non-specific binding issues • Speeds up bionalyical work-flows Sensitivity Counts SOLAµ allows users to pre-concentrate the sample up to twenty- times prior to injection, allowing greater limits of sensitivity to be achieved whilst maintaining a high level of analyte recovery, accuracy and precision. FIGURE 1. Loading capacity of 50 µL to 500 µL (top) of human plasma spiked with a polar and a non-polar compound was assessed demonstrating excellent flowthrough characteristics and reproducibly low matrix effects (bottom) Stable and contro controlling reprod low bed weight d from the sorbent. controlled, reprod plate to plate and viscous biologica processing of sam FIGURE 4. Recov plate precision 2 The Benefits of SOLAμ Technology in Sample Preparation Users can load high volumes of sample onto the SOLAµ plate and elute in as low as Users can load high volumes of sample onto the SOLAµ plate and elute in as low as 25 µL of solvent allowing greater levels of sensitivity to be achieved. Even with this low elution volume high levels of accuracy, precision, recovery and sample cleanliness are achieved. FIGURE 2. Comparison of a sample spiked with Niflumic acid before (bottom) and after (top) being taken through the SOLAµ extraction process, demonstrating a twenty-fold linear increase in response Scale Things Ethical, analytical and bioanalytical laborator SOLAµ allows users to allowing for a reductio without compromising Figure 5 demonstrates limits. 250 µL of samp sensitivity. This is due of interest from the ex Thermo Scientific Poster Note • PN20953_HPLC_2014_E_05/14S 3 Precision Matters high quality environment acy drugs and on limits to lower finement and sideration ng. The proprietary Thermo Scientific™ SOLA™ manufacturing process generates an SPE micro elution product which eliminates the issues with traditional loose-packed micro elution formats. By combining the support material and active media components into a solid uniform sorbent bed we remove the need for frits. FIGURE 5. C scale SPE ex extraction (bo FIGURE 3. SOLAμ SPE design limits issues associated with conventional SPE formats clinical research traction at very achieves this due Speed Thin prior to injection, high level of With traditional S concentration of t certain compound SOLAμ allows the achieve the requi Not only does this increases produc ma spiked with xcellent flowm) Stable and controllable flow through the SPE micro elution device is another key factor controlling reproducibility of the final analytical method. This is especially important in low bed weight devices where flow control is more difficult due to lower back pressure from the sorbent. The macro-porous structure found within SOLAμ is defined by a well controlled, reproducible manufacturing process which results in uniformity well to well, plate to plate and batch to batch. This provides an added advantage when dealing with viscous biological samples, preventing blocking and enabling high throughput processing of samples. FIGURE 4. Recovery data for SOLAμ WAX demonstrating excellent inter and intra plate precision 4 The Benefits of SOLAμ Technology in Sample Preparation e in as low as FIGURE 6. Diag conventional sc viscous biological samples, preventing blocking and enabling high throughput processing of samples. FIGURE 4. Recovery data for SOLAμ WAX demonstrating excellent inter and intra plate precision e in as low as en with this low cleanliness are SOLAμ SPE is a selectivity; • Hydrophobic R • Mixed-mode St • Mixed-mode W • Mixed-mode St • Mixed-mode W re (bottom) and onstrating a Scale Things Down With Accuracy Ethical, analytical and sample availability considerations are a challenge faced by many bioanalytical laboratories and have resulted in a drive to limit sample volume. SOLAµ allows users to directly scale down the volumes used in their analytical methods, allowing for a reduction in sample usage and eliminating issues caused by evaporation without compromising the sensitivity of their assay. Figure 5 demonstrates a ten-fold reduction in sample usage without compromising assay limits. 250 µL of sample was reduced to 25 µL of sample maintaining the same level of sensitivity. This is due to the reduction of elution volumes required to release the compound of interest from the extraction plate © 2014 Thermo F Scientific and its s This information i intellectual prope Thermo Scientific Poster Note • PN20953_HPLC_2014_E_05/14S 5 erates an SPE acked micro mponents into a FIGURE 5. Comparison of 250 μL spiked human plasma following a conventional scale SPE extraction (top) and 25 μL spiked human plasma following SOLAμ SPE extraction (bottom) tional SPE Speed Things Up With Confidence With traditional SPE the eluted sample is typically blown down to increase the concentration of the sample and thus improve the sensitivity. This causes an issue for certain compound types which can be lost during this step resulting in reduced sensitivity. SOLAμ allows the sample to be concentrated during extraction. It is therefore possible to achieve the required limits of quantitation without the need for dry down and reconstitution. Not only does this maximize recovery of the analytes it improves workflow efficiency and increases productivity. nother key factor lly important in r back pressure efined by a well mity well to well, hen dealing with ughput FIGURE 6. Diagram of a typical work flow required to concentrate samples using conventional scale SPE (top) and modified workflow utilizing SOLAμ (bottom) t inter and intra 6 The Benefits of SOLAμ Technology in Sample Preparation increases productivity. her key factor important in ack pressure ned by a well y well to well, en dealing with ghput FIGURE 6. Diagram of a typical work flow required to concentrate samples using conventional scale SPE (top) and modified workflow utilizing SOLAμ (bottom) nter and intra SOLAμ SPE is available in a wide range of chemistries to increase selectivity; • Hydrophobic Reverse Phase (HRP) for non-polar compounds • Mixed-mode Strong Cation Exchange (SCX) for basic compounds • Mixed-mode Weak Cation Exchange (WCX) for strongly basic compounds • Mixed-mode Strong Anion Exchange (SAX) for acidic compounds • Mixed-mode Weak Anion Exchange (WAX) for strongly acidic compounds aced by many me. ytical methods, evaporation romising assay ame level of ase the compound © 2014 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific and its subsidiaries. This information is not intended to encourage use of these products in any manners that might infringe the intellectual property rights of others. www.thermoscientific.com ©2014 Thermo Fisher Scientific Inc. All rights reserved. ISO is a trademark of the International Standards Organization. All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. This information is presented as an example of the capabilities of Thermo Fisher Scientific Inc. products. It is not intended to encourage use of these products in any manners that might infringe the intellectual property rights of others. Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative for details. Africa +43 1 333 50 34 0 Australia +61 3 9757 4300 Austria +43 810 282 206 Belgium +32 53 73 42 41 Brazil +55 11 3731 5140 Canada +1 800 530 8447 China 800 810 5118 (free call domestic) 400 650 5118 Denmark +45 70 23 62 60 Europe-Other +43 1 333 50 34 0 Finland +358 9 3291 0200 France +33 1 60 92 48 00 Germany +49 6103 408 1014 India +91 22 6742 9494 Italy +39 02 950 591 Japan +81 6 6885 1213 Korea +82 2 3420 8600 Latin America +1 561 688 8700 Middle East +43 1 333 50 34 0 Netherlands +31 76 579 55 55 New Zealand +64 9 980 6700 Norway +46 8 556 468 00 Thermo Fisher Scientific, Sunnyvale, CA USA is ISO 9001:2008 Certified. Russia/CIS +43 1 333 50 34 0 Singapore +65 6289 1190 Sweden +46 8 556 468 00 Switzerland +41 61 716 77 00 Taiwan +886 2 8751 6655 UK/Ireland +44 1442 233555 USA +1 800 532 4752 PN20953_E 05/14S PO20953_E 04/14S

© Copyright 2026